PPR Fiber Composite Pipe has good thermal stability and dimensional stability

The demand for high-performance piping systems has increased significantly. Among various types of plastic pipes, PPR (Polypropylene Random Copolymer) fiber composite pipe has emerged as a leading choice due to its excellent thermal stability and dimensional stability. As a professional manufacturer with over 20 years of experience in the field, Shanghai Zhongsu Pipe Co., Ltd has been at the forefront of producing high-quality PPR fiber composite pipes that meet international standards and address the evolving needs of global markets.

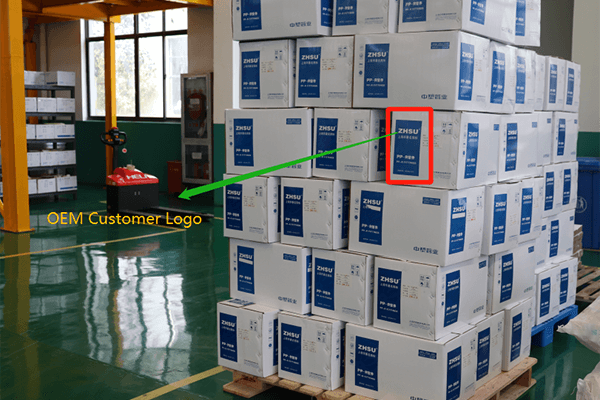

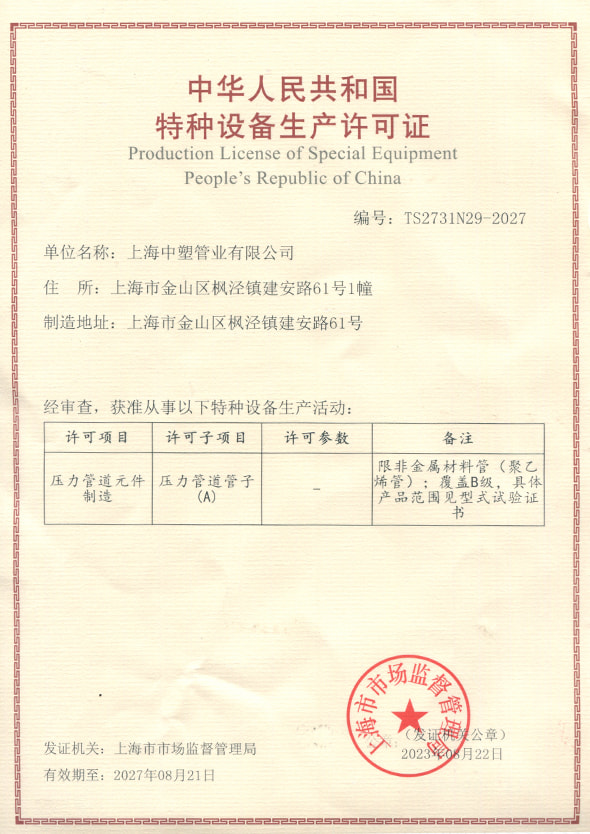

Established in 2004, Shanghai Zhongsu Pipe Co., Ltd is located in the Jinshan District of Shanghai, China. With a registered capital of RMB 1.01 billion and occupying an area of 70,000 square meters, the company has grown steadily into one of the most reputable manufacturers of plastic piping systems in China. ZHSU specializes in the production of PPR pipes and fittings , antibacterial PPR pipes , anti-UV PPR pipes , PP-RCT pipes , and HDPE pipes and fittings , serving both domestic and international markets across Southeast Asia, Africa, Latin America, and beyond.

The company adheres to a strategic development philosophy: "creating first-class enterprises, producing first-class PPR pipes & fittings, providing first-class service, establishing first-class HDPE pipes & fittings brand." This commitment to excellence has allowed ZHSU to expand its capabilities and continuously improve its product offerings, including the advanced PPR fiber composite pipe .

Understanding PPR Fiber Composite Pipe

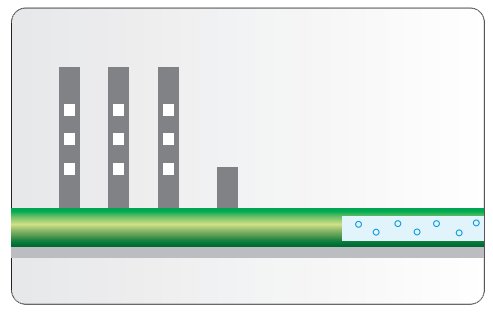

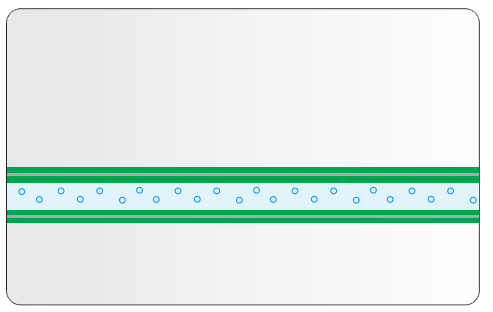

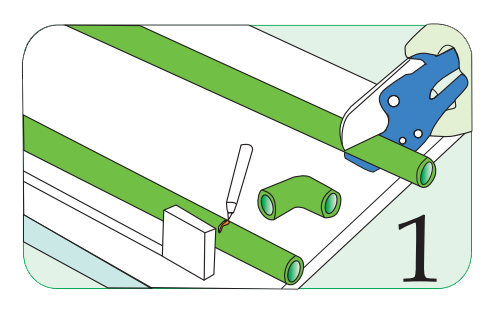

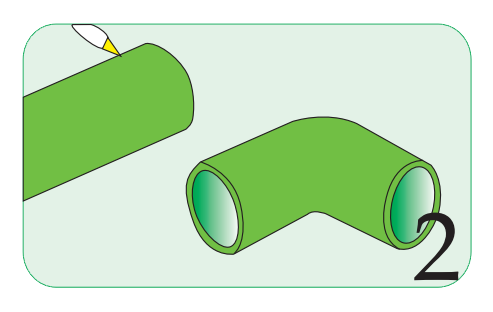

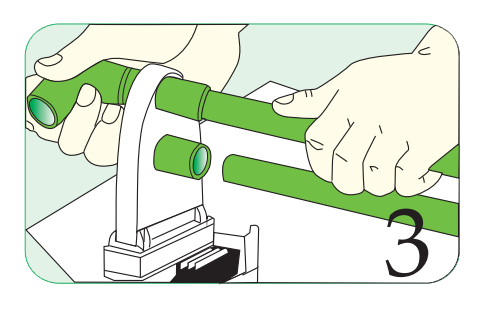

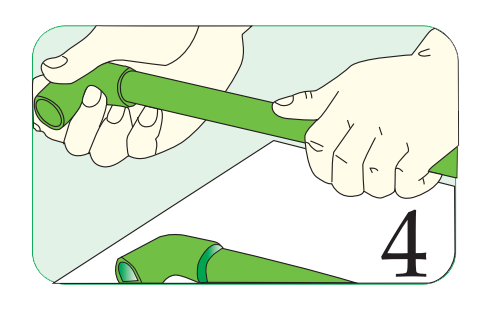

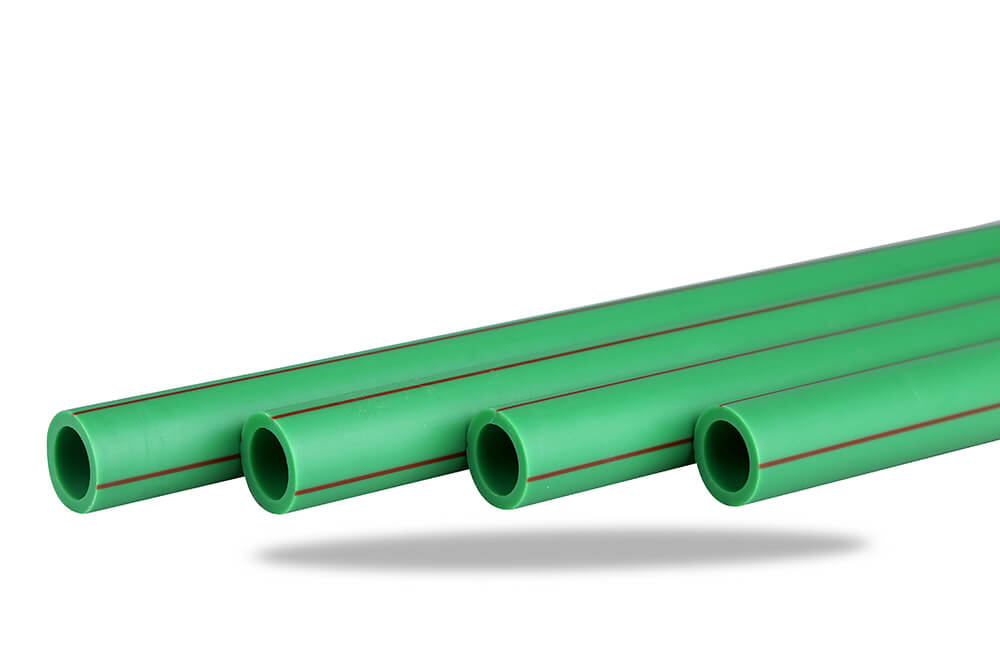

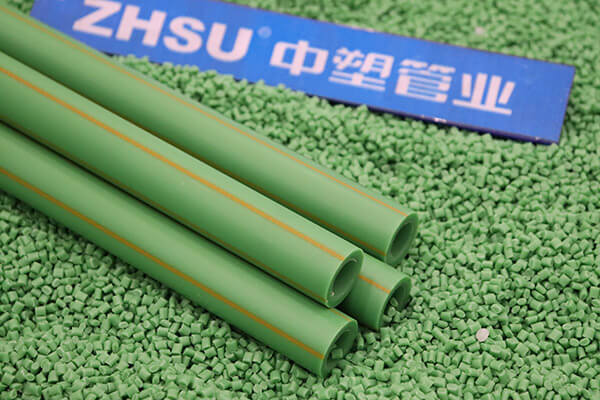

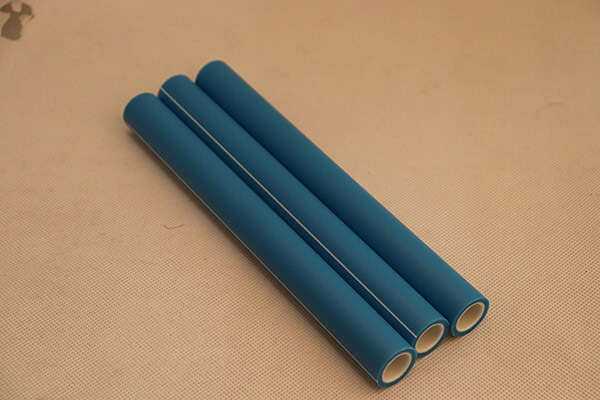

PPR fiber composite pipe is a type of enhanced polypropylene random copolymer pipe that incorporates a reinforcing layer—typically made from fiberglass or other high-strength fibers—between two layers of PPR material. This structural design provides superior mechanical strength while maintaining the inherent advantages of traditional PPR pipes, such as corrosion resistance, long service life, and ease of installation.

One of the most significant benefits of PPR fiber composite pipe is its thermal stability and dimensional stability , which are crucial factors in ensuring the reliability and durability of plumbing systems under varying temperature conditions.

Thermal Stability of PPR Fiber Composite Pipe

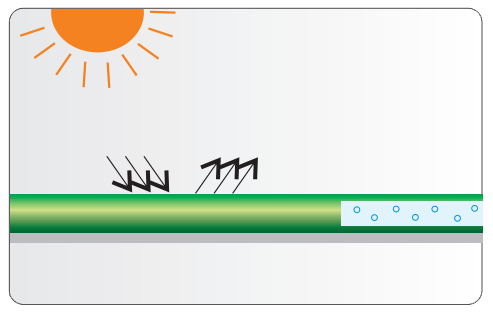

Thermal stability refers to a material’s ability to maintain its structural integrity and performance when exposed to high temperatures. In hot water distribution systems, especially those used in residential, commercial, and industrial applications, pipes must withstand elevated temperatures without deforming or deteriorating.

Traditional PPR pipes have already demonstrated good thermal resistance, typically capable of handling continuous operating temperatures up to 70°C for decades. However, when reinforced with fiber composites, the PPR fiber composite pipe achieves even better thermal performance.

This improvement comes from the integration of a high-strength fiber layer that acts as a barrier against thermal expansion and contraction. The fiber layer reduces internal stress caused by temperature fluctuations, thereby preventing deformation and extending the lifespan of the piping system.

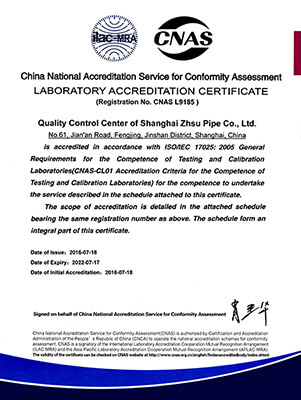

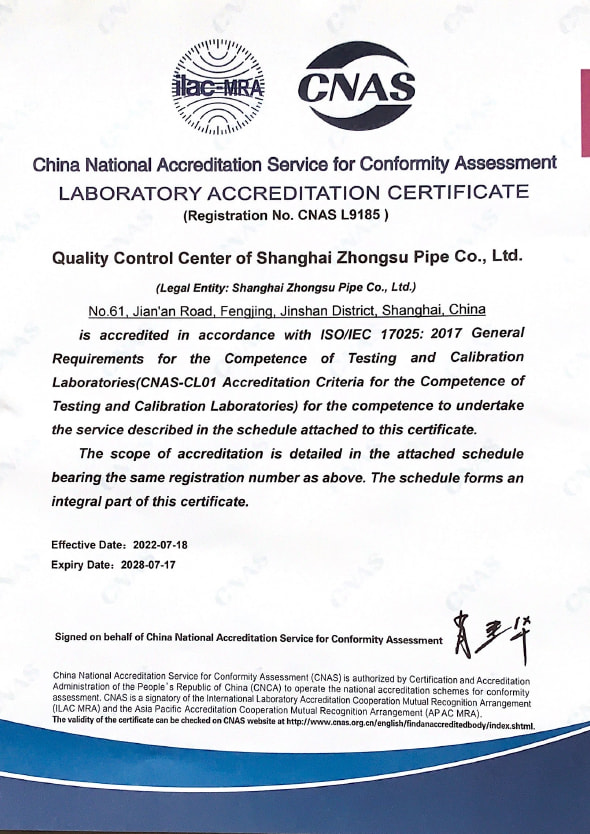

At ZHSU , our PPR fiber composite pipes undergo rigorous testing in our CNAS-certified national laboratory to ensure they can withstand prolonged exposure to high temperatures without compromising safety or efficiency. We use 100% virgin raw materials sourced from trusted suppliers like Borealis and South Korean brands, guaranteeing not only thermal stability but also environmental friendliness and safety.

Dimensional Stability of PPR Fiber Composite Pipe

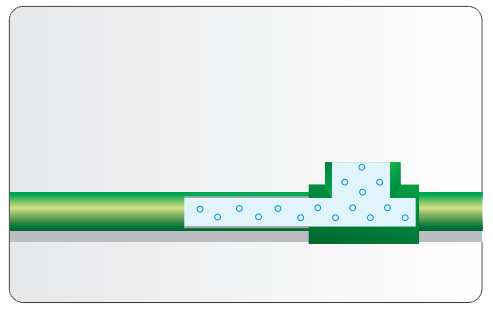

Dimensional stability refers to a material’s ability to resist changes in shape or size under external stresses such as pressure, temperature variation, or mechanical loading. For piping systems, dimensional stability is essential to prevent leaks, bursts, or misalignments during installation and operation.

PPR fiber composite pipe excels in this aspect due to the presence of the reinforcing fiber layer. This layer serves as a stabilizing core that limits radial expansion and axial elongation, making the pipe more resistant to bending, warping, or sagging over time.

Moreover, the fiber reinforcement enhances the pipe’s resistance to creep deformation—a phenomenon where materials slowly deform under constant stress over time. This characteristic is particularly important in underground installations or large-scale municipal water supply projects, where long-term structural integrity is critical.

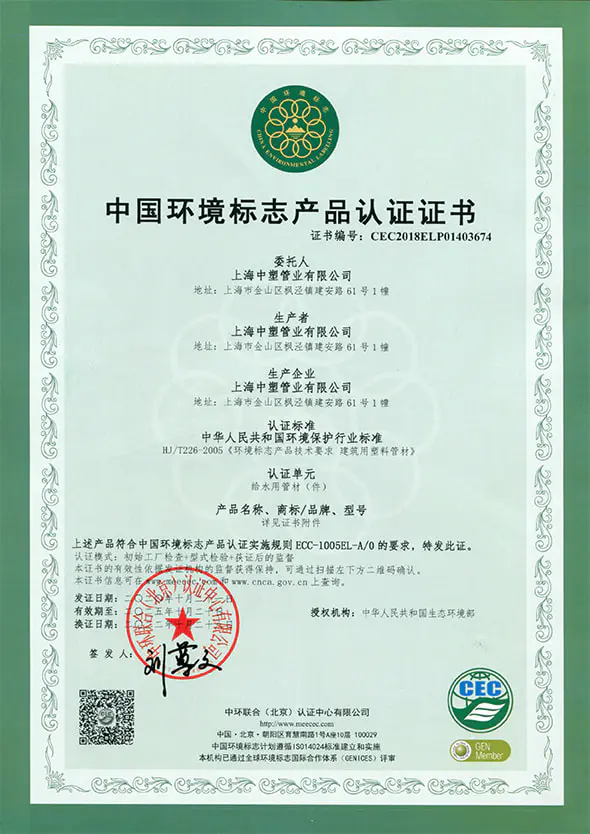

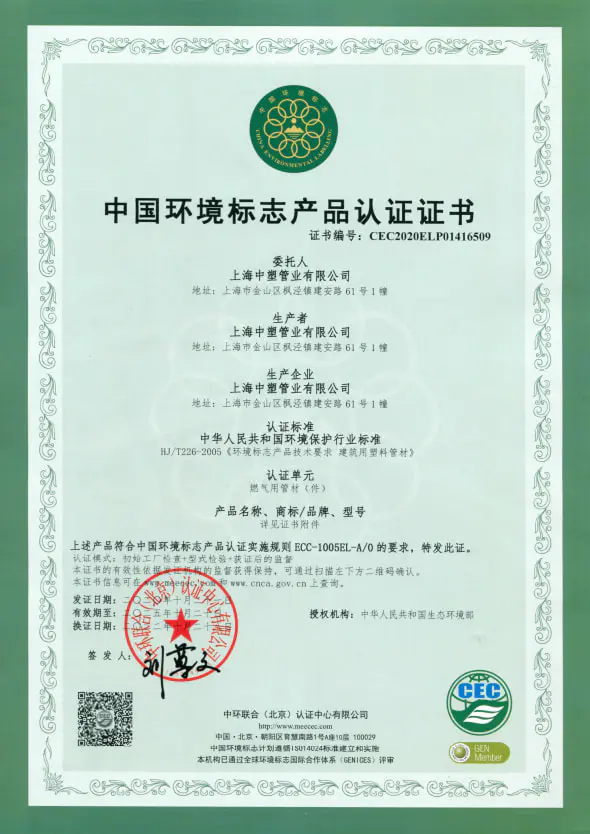

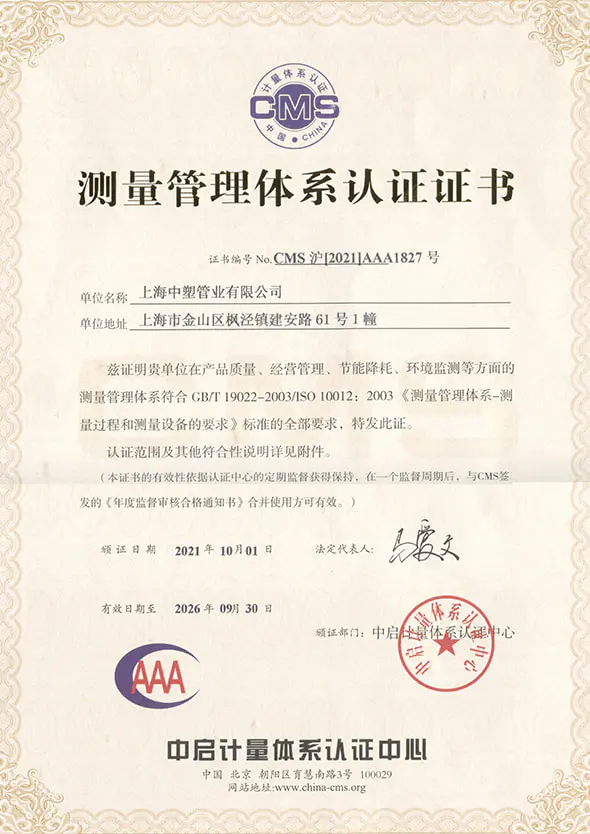

ZHSU's advanced production lines and strict quality control processes ensure that each batch of PPR fiber composite pipe maintains consistent dimensions and mechanical properties. Our products comply with national and international standards, including ISO9001, ISO14001, and OHSAS18001 certifications, reflecting our commitment to quality and reliability.

Applications of PPR Fiber Composite Pipe

Thanks to its excellent thermal and dimensional stability, PPR fiber composite pipe is widely used in various applications:

Building Water Supply Systems : Ideal for hot and cold water distribution in residential and commercial buildings.

Municipal Water Supply and Drainage : Suitable for long-distance water transmission due to its durability and leak-proof joints.

Underground Drainage and Sewage Discharge : Resistant to soil movement and temperature changes, ensuring stable performance.

Industrial Process Piping : Capable of transporting hot fluids in chemical, food processing, and pharmaceutical industries.

Rural Drinking Water Projects : A preferred solution for large-scale rural water network transformation due to its cost-effectiveness and longevity.

ZHSU has played a key role in supporting national infrastructure projects, including rural drinking water safety initiatives and nuclear power plant construction. Our company has invested in large-diameter PE production facilities, enabling us to produce PE pipes up to DN1200mm , further expanding our capability to meet complex engineering requirements.

Why Choose ZHSU for PPR Fiber Composite Pipe?

As a certified "Shanghai Famous Brand Product" , "Shanghai High-Tech Enterprise" , and "Shanghai Famous Trademark" , ZHSU combines innovation, quality, and customer-centric service to deliver world-class piping solutions.

Our strengths include:

Advanced Production Technology : Equipped with internationally leading production lines and inspection equipment.

High-Quality Raw Materials : Use of 100% virgin-grade resins ensures product safety and longevity.

Strict Quality Control : Comprehensive monitoring from raw material procurement to final delivery.

Professional Technical Support : Experienced engineers and after-sales teams provide tailored solutions.

Global Market Presence : Products exported to over 50 countries and regions worldwide.

PPR fiber composite pipe offers outstanding thermal stability and dimensional stability, making it a superior choice for modern piping systems. At Shanghai Zhongsu Pipe Co., Ltd , we are proud to lead the industry in developing and manufacturing these advanced pipes that combine functionality, durability, and sustainability.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie