PPR Pipe for Potable Water has a reliable connection method and can effectively prevent the risk of leakage in drinking water systems.

In modern urban and rural water supply systems, the reliability of piping materials and their connection methods play a crucial role in ensuring safe and sustainable drinking water delivery. Among various plastic pipe solutions, PPR Pipe for Potable Water have emerged as one of the most preferred choices for potable water applications due to their excellent performance, environmental friendliness, and reliable jointing technology. As a leading manufacturer in this field, Shanghai Zhongsu Pipe Co., Ltd. has been at the forefront of developing high-quality PPR pipes and fittings that offer secure connections and significantly reduce the risk of leakage.

Introduction to PPR Pipes

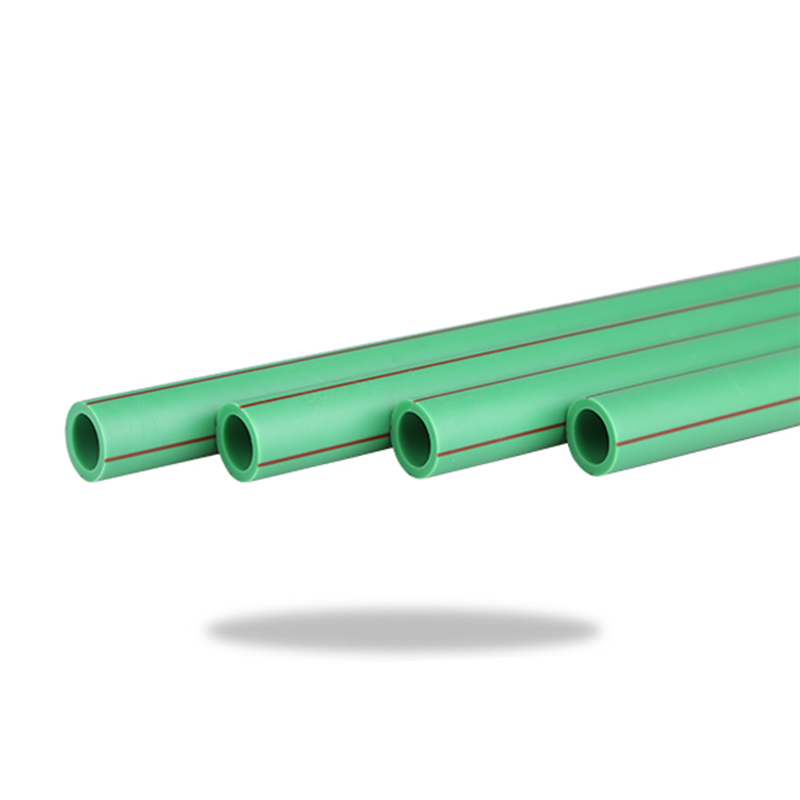

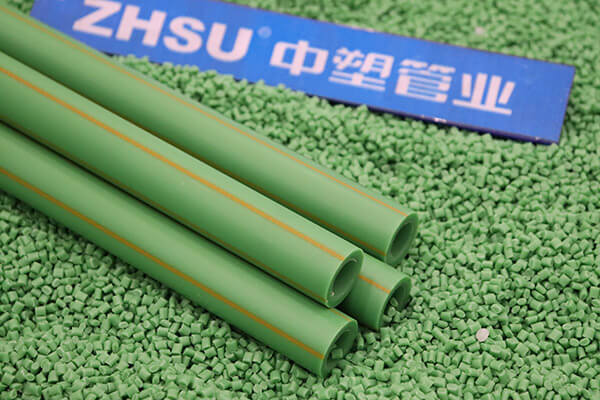

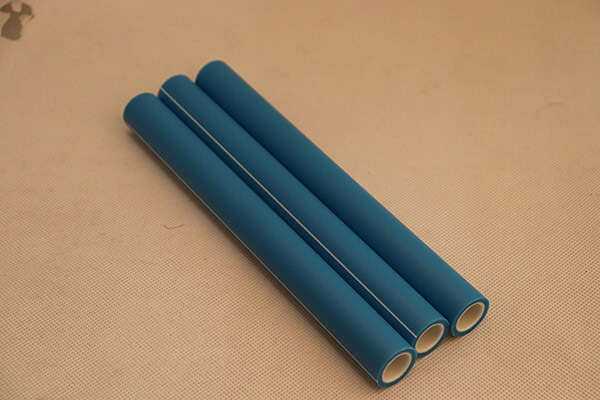

PPR pipes are thermoplastic piping systems widely used in hot and cold water distribution systems within residential, commercial, and industrial buildings. Their molecular structure provides superior resistance to temperature variations, chemical corrosion, and long-term durability. One of the most significant advantages of PPR pipes is their heat fusion connection method, which eliminates the need for mechanical joints or adhesives that could potentially fail over time.

This seamless joining process ensures that the pipeline system remains leak-proof, maintaining water quality and minimizing maintenance costs. In drinking water systems, where contamination risks must be minimized, the integrity of each joint is critical. The use of PPR pipes with proper fusion techniques offers an effective solution to these challenges.

Shanghai Zhongsu Pipe Co., Ltd.: A Trusted Manufacturer

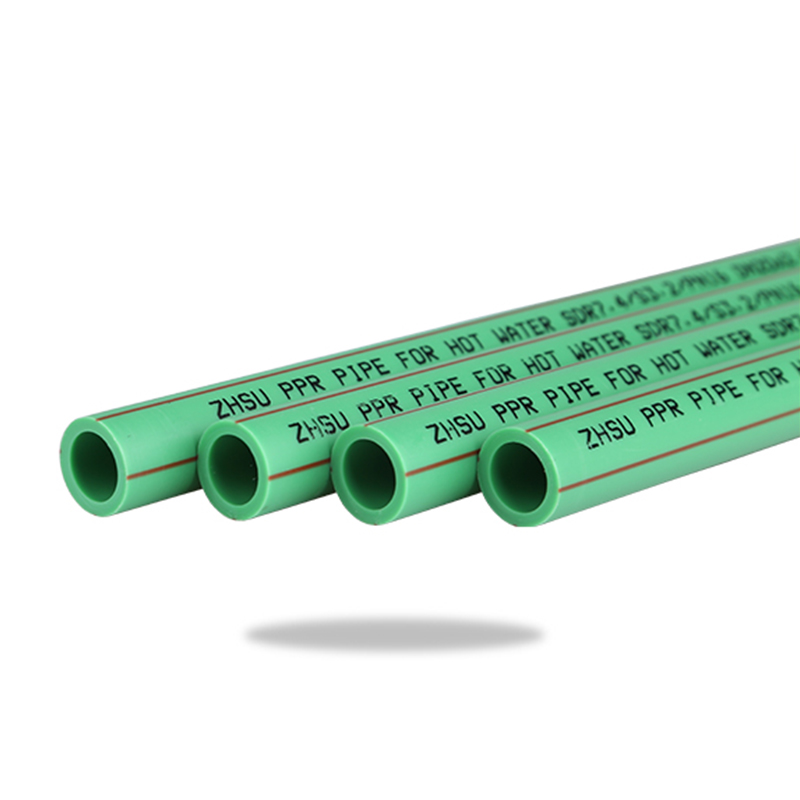

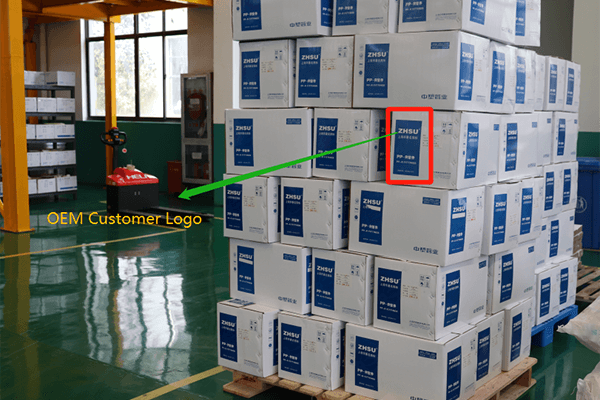

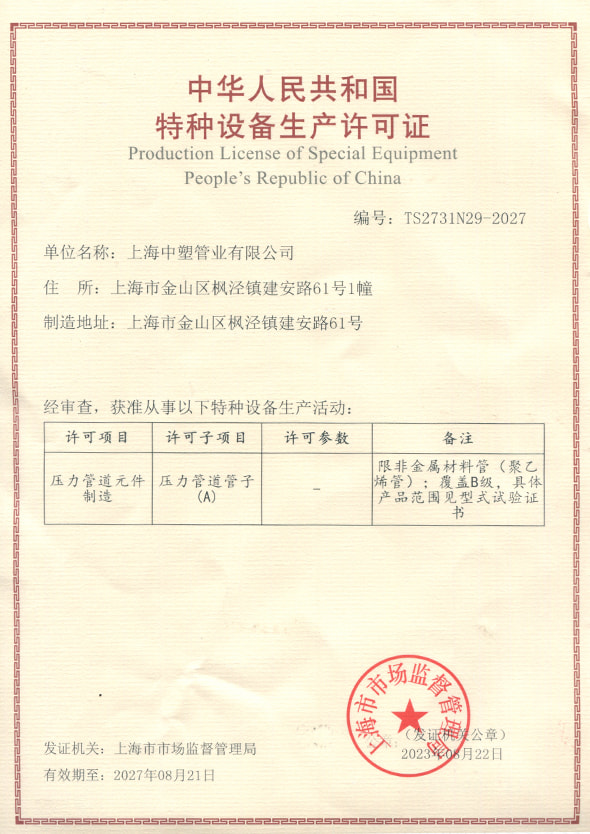

Established in 2004 with a registered capital of RMB 1.01 billion, Shanghai Zhongsu Pipe Co., Ltd. (ZHSU) is located in the Jinshan District of Shanghai, China, occupying more than 70,000 square meters. With over two decades of experience in the industry, ZHSU has become a well-known enterprise specializing in the production of PPR pipes and fittings, antibacterial PPR pipes, anti-UV PPR pipes, PP-RCT pipes, HDPE pipes, and related fittings.

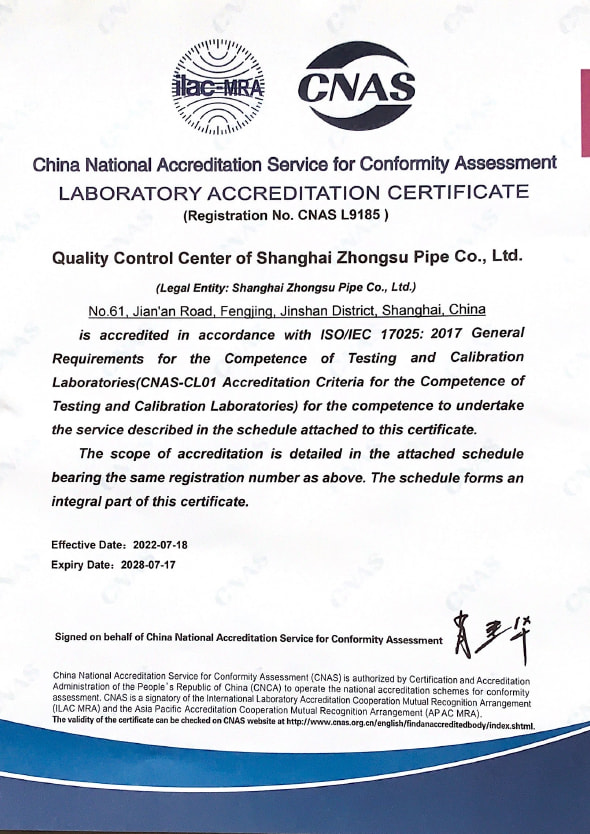

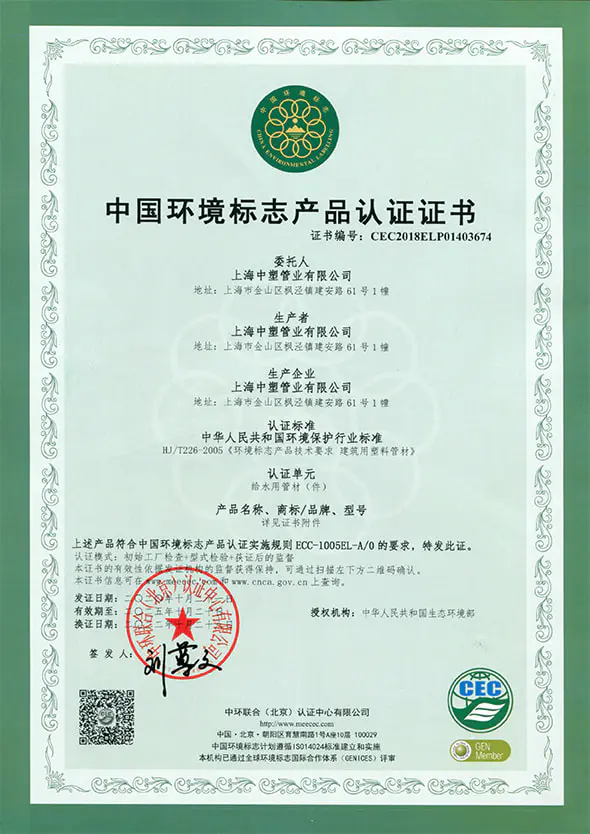

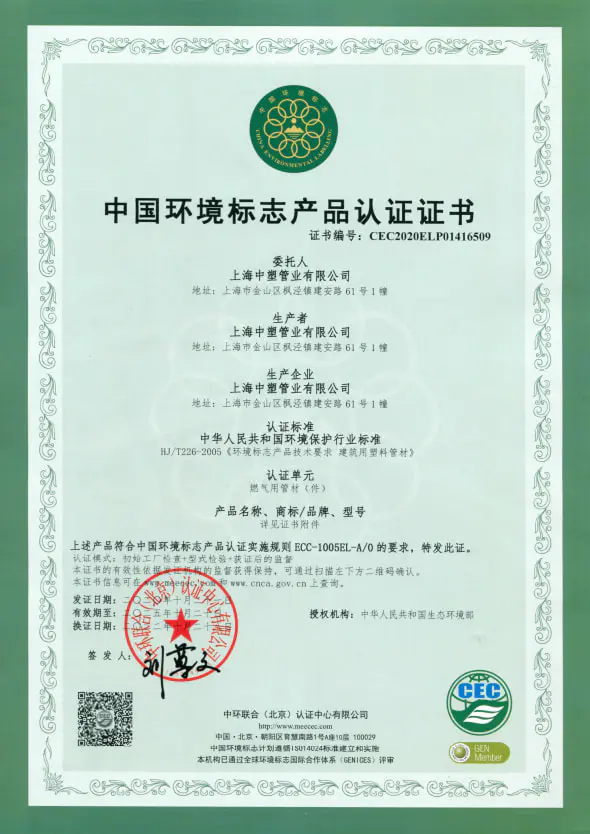

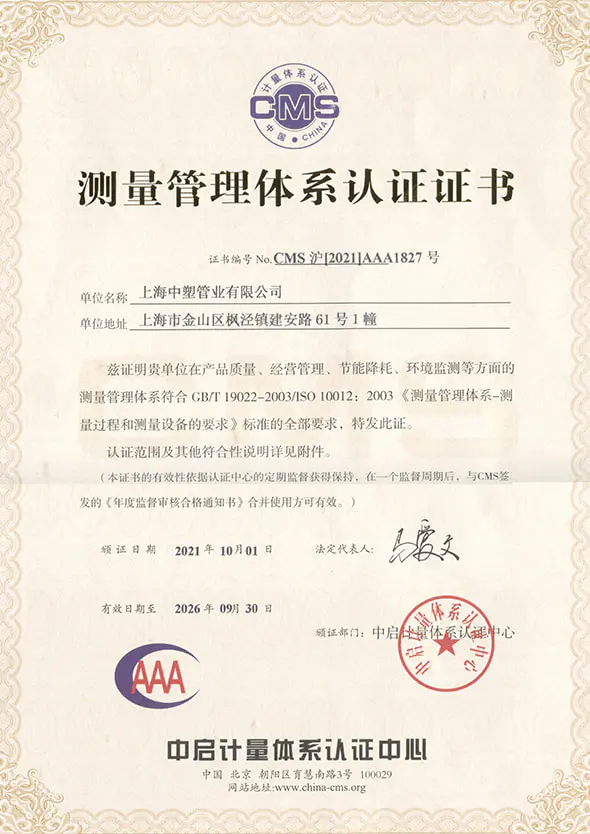

ZHSU adopts advanced production lines and inspection equipment to ensure high productivity and fast lead times. Its national laboratory, certified by CNAS (China National Accreditation Service for Conformity Assessment), guarantees strict quality control from raw material selection to final product delivery. All products are made from 100% virgin raw materials sourced from reputable suppliers such as Borealis and top domestic brands, ensuring environmental safety and long-term performance.

The company adheres to a strategic vision of “creating first-class enterprises, producing first-class PPR pipes & fittings, providing first-class service, and establishing a first-class HDPE pipes & fittings brand.” This commitment has driven steady growth and earned ZHSU recognition as a “Shanghai Famous Brand Product,” “Shanghai High-Tech Enterprise,” and “Shanghai Famous Trademark.”

Reliable Connection Methods of PPR Pipes

One of the key features that make PPR pipes ideal for potable water systems is their reliable connection method—heat fusion jointing. Unlike traditional metal pipes that rely on threaded or flanged connections, PPR pipes are joined using specialized welding machines that melt both the pipe end and the fitting socket simultaneously. Once cooled, the joint becomes a single, continuous piece with no weak points.

This method eliminates common leakage sources such as rubber seals degradation, improper tightening, or corrosion. Additionally, since there are no additional sealing materials required, the risk of contamination from foreign substances is minimized, making it especially suitable for clean water applications.

ZHSU’s PPR Water Pipes are designed and manufactured in accordance with national and international standards, including ISO 9001, ISO 14001, and OHSAS 18001 certifications. These standards ensure that every stage—from raw material procurement to finished product delivery—is under strict quality monitoring.

Application of PPR Pipes in Drinking Water Systems

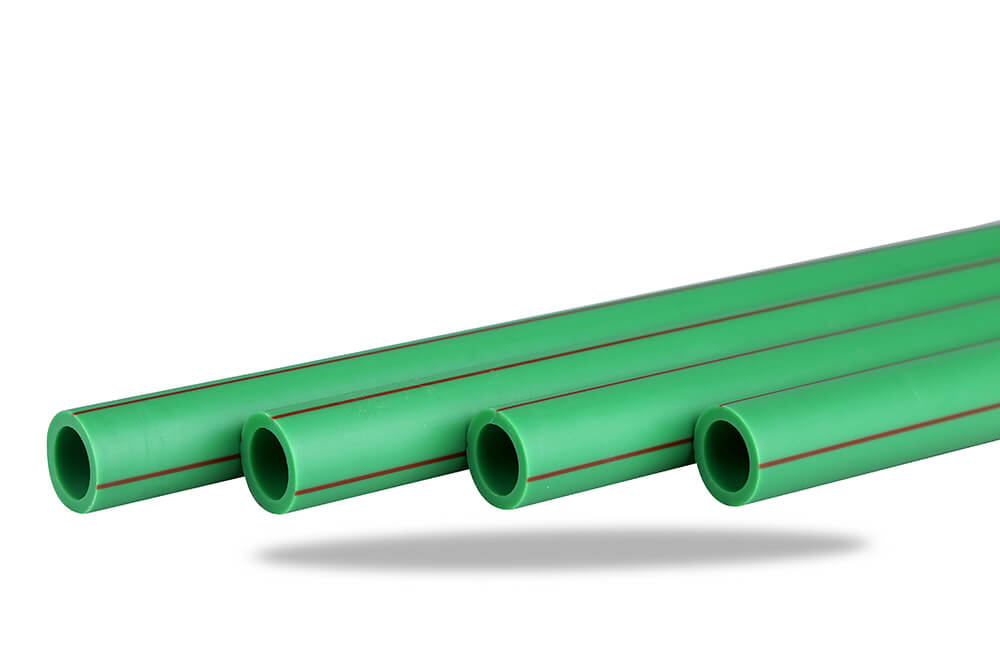

ZHSU’s Hot Water PPR Pipes and fittings are extensively used in various sectors, including:

Building water supply and drainage systems

Municipal water supply networks

Rural water network transformation projects

Commercial and residential plumbing systems

In particular, ZHSU has actively participated in nationwide rural drinking water safety projects and nuclear power plant infrastructure developments. To meet the growing demand for large-diameter piping solutions, ZHSU has invested in state-of-the-art PE production facilities capable of manufacturing pipes up to DN1200mm in diameter—an impressive achievement that positions ZHSU among the few manufacturers in China capable of producing such large-scale pipelines.

These capabilities not only enhance ZHSU’s competitiveness in the domestic market but also support its global expansion. Today, ZHSU’s products are exported to Southeast Asia, Africa, Latin America, and other regions, where they are highly regarded for their reliability, safety, and environmental sustainability.

As cities expand and water resources become increasingly precious, the importance of reliable and sustainable piping systems cannot be overstated. PPR Cold Water Pipe, with their proven track record in potable water applications, offer a robust and efficient solution to the challenges of modern water distribution.

With its extensive experience, cutting-edge technology, and unwavering commitment to quality, Shanghai Zhongsu Pipe Co., Ltd. stands out as a trusted partner in delivering safe, durable, and environmentally responsible piping solutions. Whether for municipal infrastructure or individual building projects, ZHSU’s PPR pipes provide a reliable connection method that effectively prevents leakage risks in drinking water systems—ensuring clean water access for generations to come.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie