Comprehensive evaluation of temperature resistance, pressure resistance and antibacterial stability of PPR Antibacterial Pipe

In today’s infrastructure and construction industries, the demand for reliable, durable, and safe piping systems has grown significantly. With increasing concern for public health and hygiene, antibacterial piping solutions have gained widespread attention. Among these, the PPR antibacterial pipe has emerged as a preferred solution for domestic and industrial water supply systems due to its excellent chemical and physical properties. Shanghai Zhongsu Pipe Co., Ltd. (ZHSU), a leading manufacturer in this field, has been at the forefront of innovation and quality in plastic piping systems. This article provides a comprehensive evaluation of the temperature resistance, pressure resistance, and antibacterial stability of PPR antibacterial pipes, with special emphasis on the contributions and product standards maintained by ZHSU.

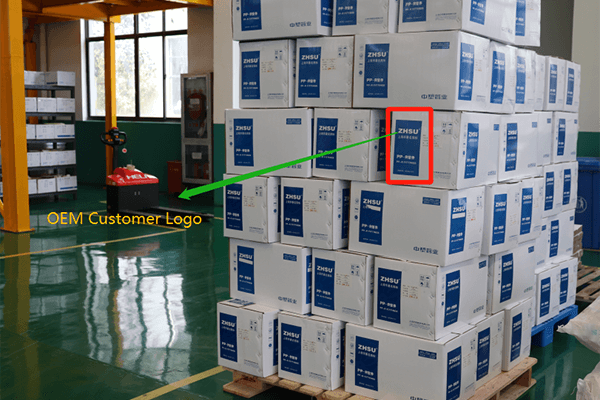

Established in 2004, Shanghai Zhongsu Pipe Co., Ltd (ZHSU) is a prominent manufacturer specializing in the production of high-performance plastic pipe systems. With a registered capital of 1.01 billion RMB and a sprawling 70,000-square-meter facility in Jinshan District, Shanghai, ZHSU has become a symbol of reliability and technological advancement in China’s piping industry.

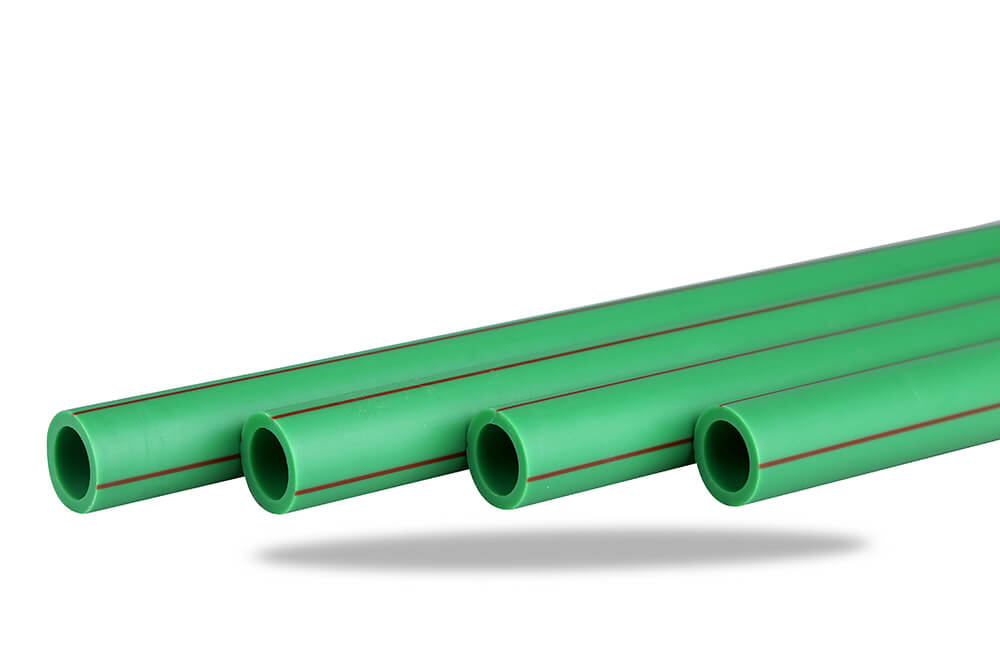

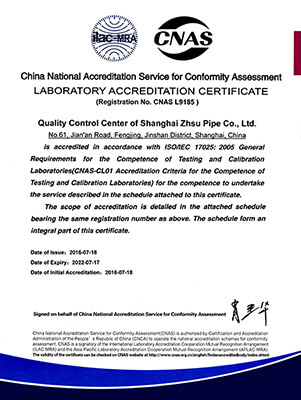

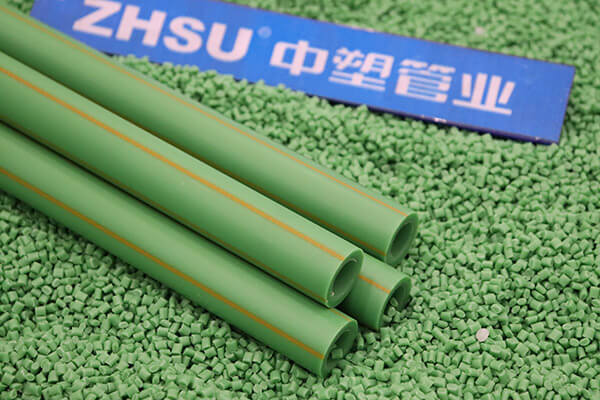

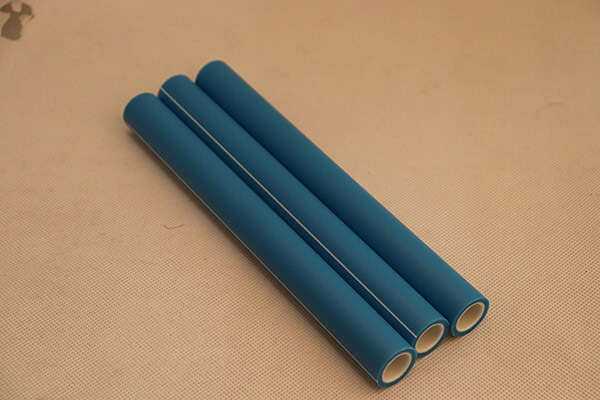

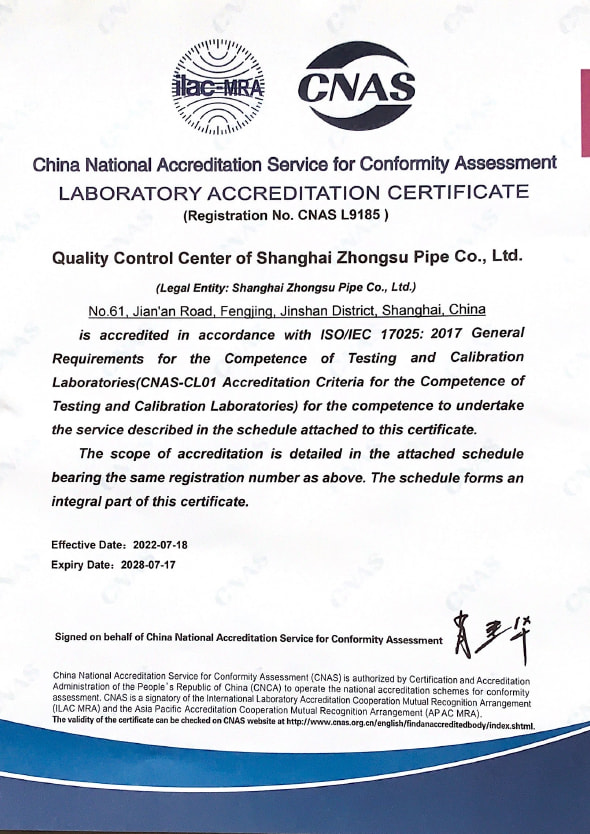

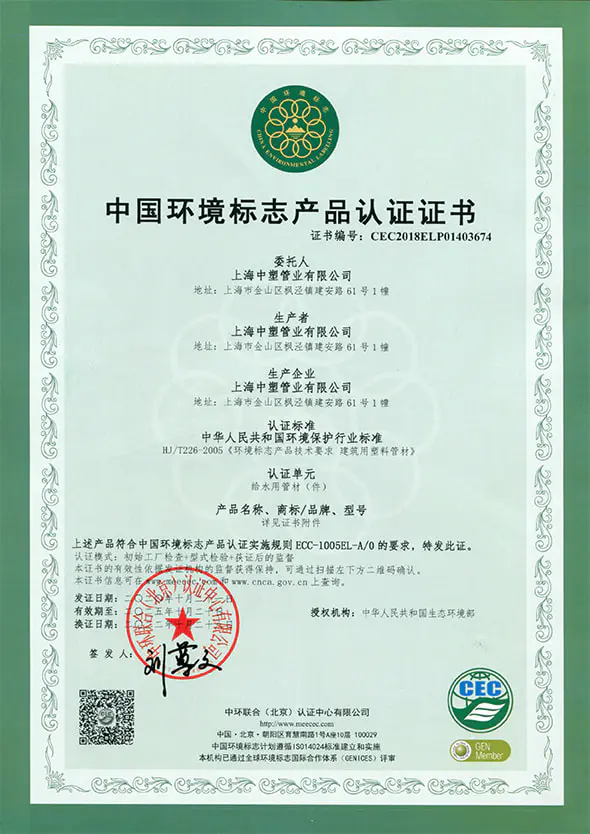

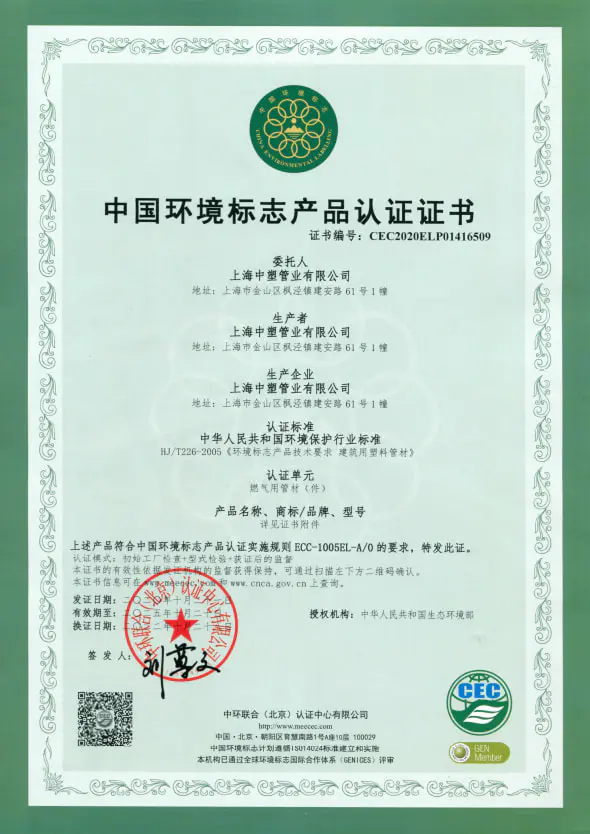

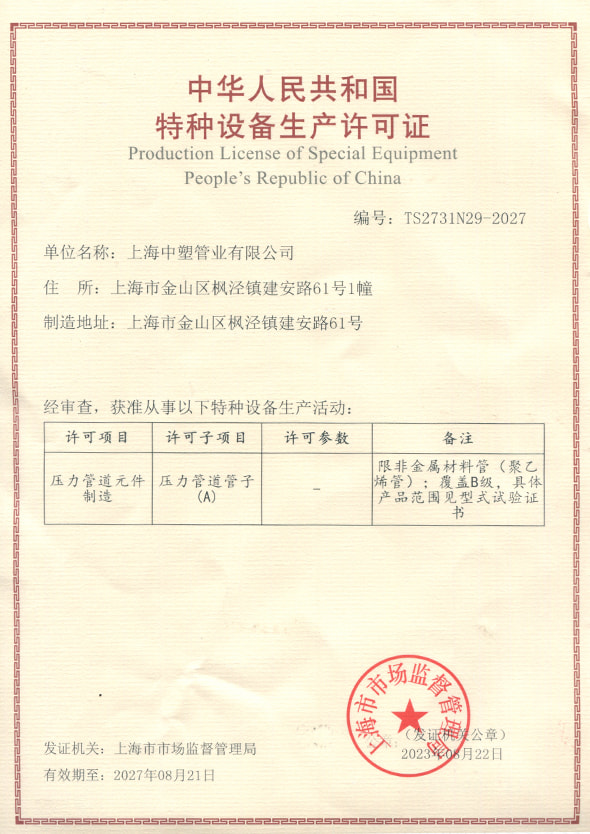

The company’s core product offerings include PPR pipes and fittings, antibacterial PPR pipes and fittings, anti-UV PPR pipes, PP-RCT pipes, and HDPE water supply and drainage pipes. ZHSU operates fully automated production lines equipped with cutting-edge inspection and testing facilities. Notably, it maintains a CNAS-accredited national laboratory and utilizes 100% virgin raw materials sourced from international and domestic premium suppliers such as Borealis and leading South Korean brands. These features ensure that ZHSU products are environmentally friendly, safe, and aligned with both national and international quality standards.

Temperature Resistance of PPR Antibacterial Pipe

Polypropylene Random Copolymer (PPR) is well-known for its high resistance to temperature, making it suitable for hot and cold water distribution systems. ZHSU’s PPR antibacterial pipes are manufactured using advanced extrusion technology, which improves the molecular structure and overall heat endurance of the pipe material.

The pipes are capable of withstanding operating temperatures up to 70°C for hot water systems, with short-term tolerance reaching 95°C. This temperature resistance makes ZHSU’s antibacterial PPR pipes ideal for central heating systems, industrial fluid transport, and domestic hot water supply, especially in regions with variable climate conditions.

ZHSU’s proprietary manufacturing process includes optimized crystallization and the integration of thermally stable antibacterial agents, which ensures that performance is maintained under prolonged thermal stress. In tests conducted at the company’s national laboratory, the pipes retained over 95% of their mechanical integrity after long-duration exposure to elevated temperatures, affirming their reliability in real-world applications.

Pressure Resistance and Structural Integrity

Pressure resistance is a critical parameter for any piping system, especially in high-rise buildings and municipal infrastructure projects. ZHSU’s antibacterial PPR pipes exhibit excellent mechanical strength due to the integration of high-modulus PPR resin and advanced reinforcement technologies.

The pipes conform to ISO15874 and GB/T 18742 standards, and are rated for various pressure classes including PN10, PN16, PN20, and PN25. The use of high-grade raw materials and advanced manufacturing methods ensures uniform wall thickness and homogenous molecular distribution, contributing to superior burst strength and long-term hydrostatic resistance.

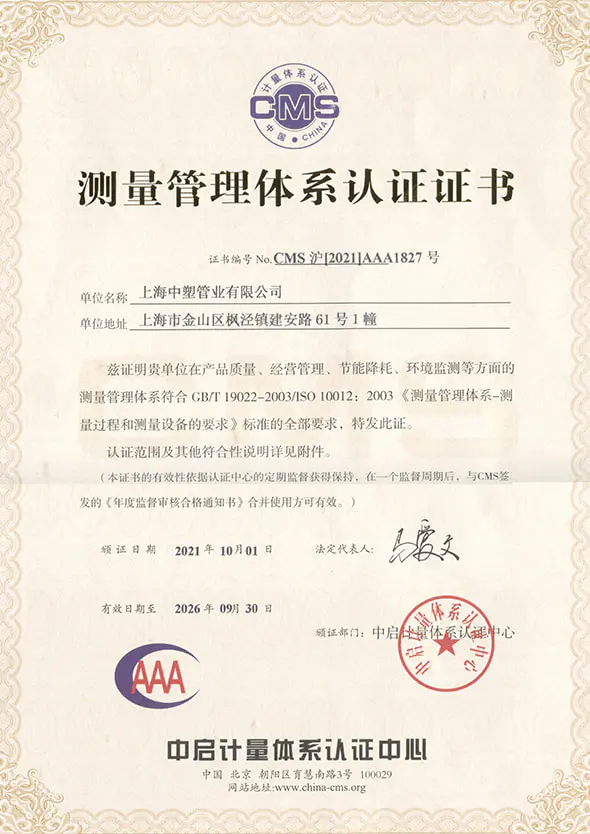

ZHSU adopts a rigorous quality control process from raw material inspection to final product delivery. Each batch undergoes hydraulic pressure testing, thermal cycling tests, and impact resistance assessments in accordance with ISO and CNAS protocols. This meticulous attention to detail has enabled ZHSU to maintain certification under ISO9001 (Quality Management), ISO14001 (Environmental Management), and OHSAS18001 (Occupational Health & Safety).

In practice, ZHSU’s antibacterial PPR pipes have been widely applied in high-pressure systems, including residential complexes, hospitals, schools, and public buildings, demonstrating consistent durability and structural integrity over years of use.

Antibacterial Stability and Health Safety

One of the key differentiators of ZHSU’s PPR antibacterial pipes is their incorporation of silver ion-based antibacterial agents directly into the polymer matrix during production. This provides long-lasting antibacterial protection that is resistant to washing or surface abrasion.

Third-party laboratory testing confirms that these antibacterial pipes effectively inhibit common bacteria such as E. coli, Staphylococcus aureus, and Pseudomonas aeruginosa, with a bacterial reduction rate of over 99%. The antibacterial function is particularly vital in water distribution systems where stagnant water may lead to microbial growth, which can compromise water safety and human health.

ZHSU’s CNAS-accredited laboratory conducts microbiological testing on all antibacterial product lines, ensuring compliance with Chinese standard GB/T 31417 and the European standard ISO 22196. The integration of non-leaching antibacterial technology ensures stability throughout the lifecycle of the product, making it suitable for sensitive applications like hospital water systems, food processing, and rural drinking water projects.

To support large-scale infrastructure development, ZHSU has expanded its production capacity for large-diameter pipes. The company now offers HDPE and PE pipes up to DN1200mm, making it one of the few manufacturers in China capable of producing such large-scale components.

ZHSU products are not only dominant in the domestic Chinese market but also enjoy a strong international presence across Southeast Asia, Africa, and Latin America. The company’s reputation for quality and reliability has led to it being named a “Shanghai Famous Brand Product” and recognized as a “Shanghai High-Tech Enterprise.”

Commitment to Excellence and Future Outlook

At the heart of ZHSU’s success lies its unwavering commitment to excellence and innovation. Guided by its corporate philosophy — "Knowledge, Courage, Truth-Seeking, Innovation" — and the enterprise values of "Customer First, Quality, Management Efficiency, Reputation and Sincerity", the company continuously pushes the boundaries of product development.

Looking forward, ZHSU aims to enhance its R&D capabilities, improve automation and smart manufacturing, and strengthen partnerships globally. By maintaining its focus on eco-friendly and health-conscious solutions, ZHSU is poised to be a global leader in sustainable plastic piping systems.

The PPR antibacterial pipes produced by Shanghai Zhongsu Pipe Co., Ltd. represent a pinnacle of modern polymer engineering. Their superior temperature resistance, outstanding pressure handling capabilities, and proven antibacterial performance make them ideal for a wide range of water supply and drainage systems.

ZHSU’s focus on quality assurance, environmental responsibility, and technological innovation ensures that its products not only meet but exceed the expectations of customers both in China and internationally. With growing global demand for hygienic and durable piping solutions, ZHSU’s antibacterial PPR pipes stand out as a testament to the company’s vision — to create first-class enterprises and provide first-class products and services to the world.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie