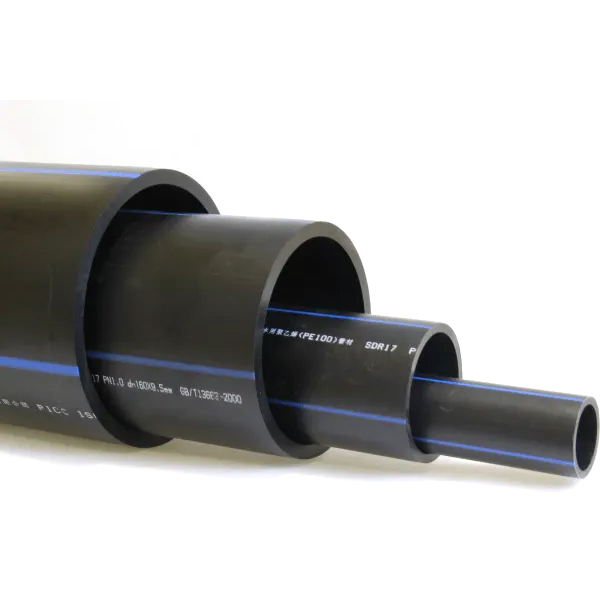

HDPE Water Pipe has excellent corrosion resistance and is suitable for water supply systems in a variety of complex environments.

In the modern era of infrastructure development, the choice of piping materials plays a crucial role in ensuring long-term reliability, safety, and efficiency of water supply systems. Among the various types of plastic pipes available today, HDPE (High-Density Polyethylene) water pipe stands out due to its excellent corrosion resistance, making it an ideal solution for water distribution in complex environments. Shanghai Zhongsu Pipe Co., Ltd., with over 20 years of experience and expertise, has emerged as a leading manufacturer of high-quality HDPE pipes and fittings, contributing significantly to sustainable water management solutions globally.

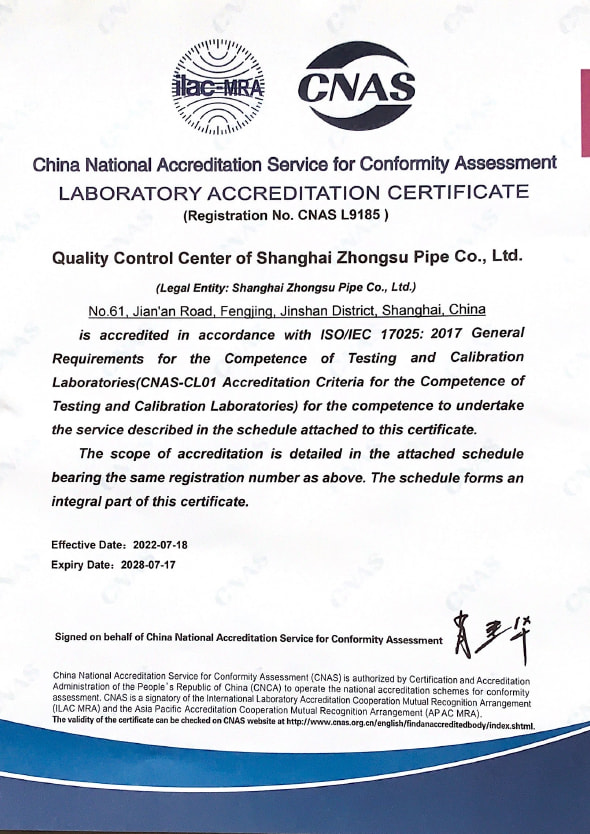

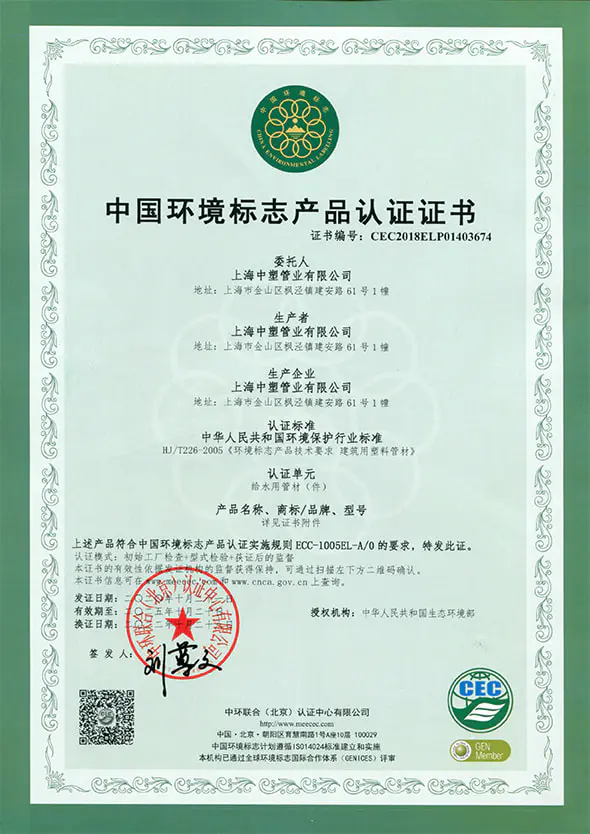

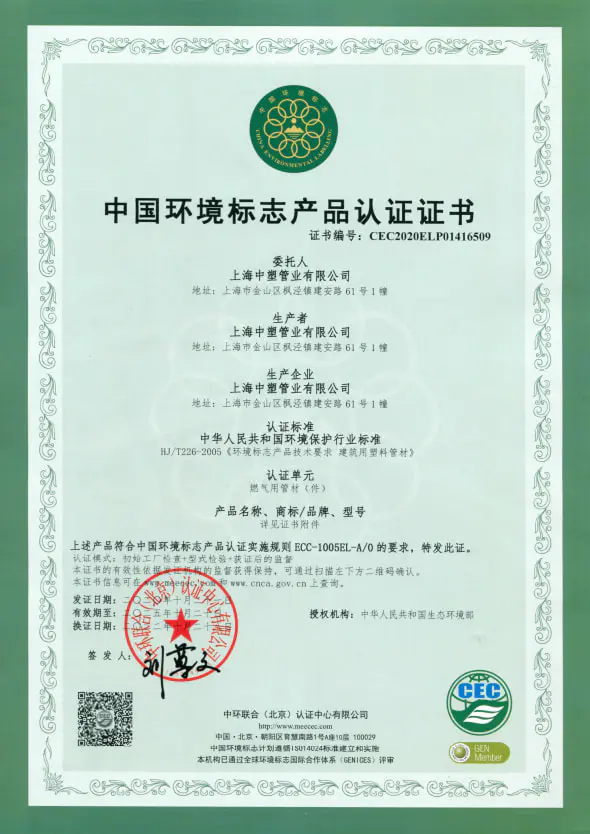

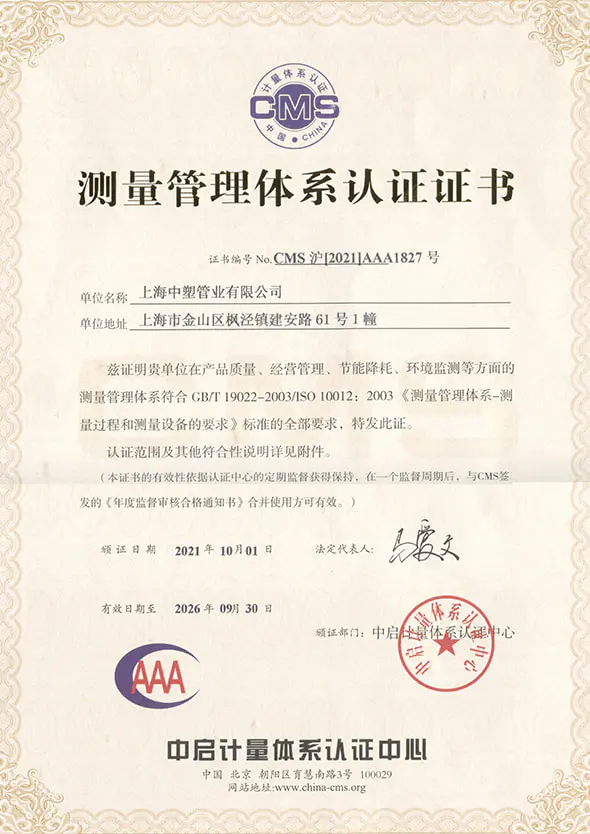

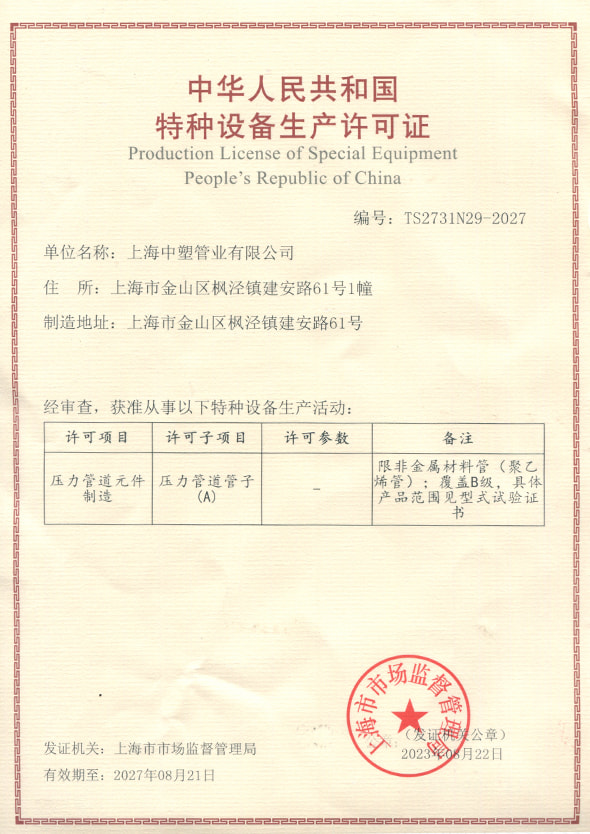

Shanghai Zhongsu Pipe Co., Ltd. specializes in producing HDPE pipes that meet national and international standards, including ISO9001, ISO14001, and OHSAS18001. With a registered capital of RMB 1.01 billion and a production base covering 70,000 square meters in Shanghai's Jinshan District, the company has invested heavily in advanced manufacturing technology and quality control systems to deliver top-tier products to global markets.

Corrosion Resistance: A Key Advantage of HDPE Pipes

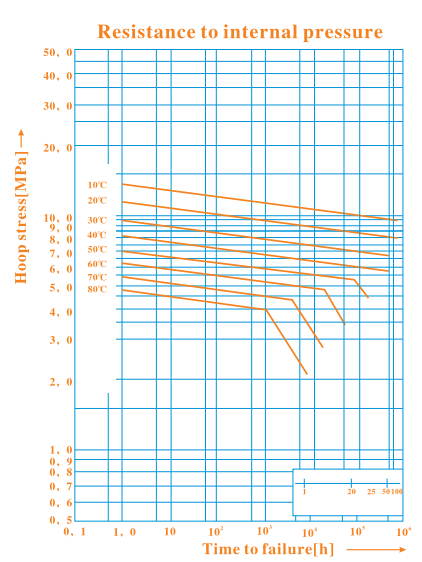

Corrosion is one of the primary causes of pipeline failure, especially in environments where soil acidity, salinity, or industrial pollutants are present. HDPE pipes are chemically inert, meaning they do not react with acids, alkalis, or salts found in soil or water. This inherent property ensures that HDPE pipes remain unaffected by electrochemical reactions, microbial corrosion, or oxidative degradation—common issues that plague metal-based piping systems.

Shanghai Zhongsu Pipe Co., Ltd. uses 100% virgin raw materials sourced from reputable brands such as Borealis and South Korean suppliers, guaranteeing the environmental friendliness and mechanical strength of its HDPE pipes. The company’s CNAS-certified national laboratory ensures rigorous testing and inspection throughout the production process, from raw material selection to final product delivery. As a result, ZHSU’s HDPE pipes exhibit superior performance in aggressive environments, including coastal areas, industrial zones, and regions with acidic groundwater.

Wide Applicability Across Diverse Environments

The versatility of Water Supply HDPE Pipe makes them suitable for a wide range of applications. Whether used in municipal water supply networks, rural drinking water projects, or large-scale industrial facilities, HDPE pipes offer unmatched adaptability. Their flexibility allows for easy installation even in uneven terrain, reducing the need for additional fittings and joints that can become potential leakage points.

Shanghai Zhongsu Pipe Co., Ltd. has developed a comprehensive product line that includes HDPE water supply and drainage pipes, with diameters reaching up to DN1200mm—a testament to the company's technological capabilities and commitment to meeting diverse infrastructure needs. This large-diameter capability enables ZHSU to serve major municipal and industrial projects, including nuclear power plant cooling systems and large-scale sewage discharge pipelines.

The company’s HDPE Water Pipes have been successfully deployed in various complex environments across China and overseas markets, including Southeast Asia, Africa, and Latin America. In these regions, where water infrastructure often faces challenges such as extreme weather conditions, poor soil stability, and limited maintenance resources, HDPE pipes provide a durable and cost-effective solution.

ZHSU’s HDPE pipes are fully recyclable and do not release toxic substances during their lifecycle, making them an eco-friendly alternative to traditional piping materials. Additionally, the long service life of HDPE pipes—often exceeding 50 years—reduces the frequency of replacements and associated environmental impacts. By adopting stringent quality management systems and earning certifications such as ISO14001 (Environmental Management System), the company demonstrates its dedication to minimizing ecological footprints while delivering high-performance products.

With state-of-the-art production lines and inspection equipment, ZHSU ensures that every HDPE pipe leaving its factory meets the highest quality standards. The company also collaborates closely with government agencies, engineering firms, and international partners to support critical infrastructure projects, including nationwide rural drinking water safety programs and urban underground utility networks.

HDPE water pipes possess exceptional corrosion resistance, making them an ideal choice for water supply systems operating in a variety of complex environments. Shanghai Zhongsu Pipe Co., Ltd., as a leader in the industry, continues to set benchmarks in product quality, innovation, and customer satisfaction. Through its commitment to excellence, environmental stewardship, and technological advancement, ZHSU is playing a vital role in shaping the future of sustainable water infrastructure around the world.

Whether in bustling metropolitan cities or remote rural communities, HDPE pipes from Shanghai Zhongsu Pipe Co., Ltd. offer reliable, efficient, and environmentally friendly solutions for modern water management.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie