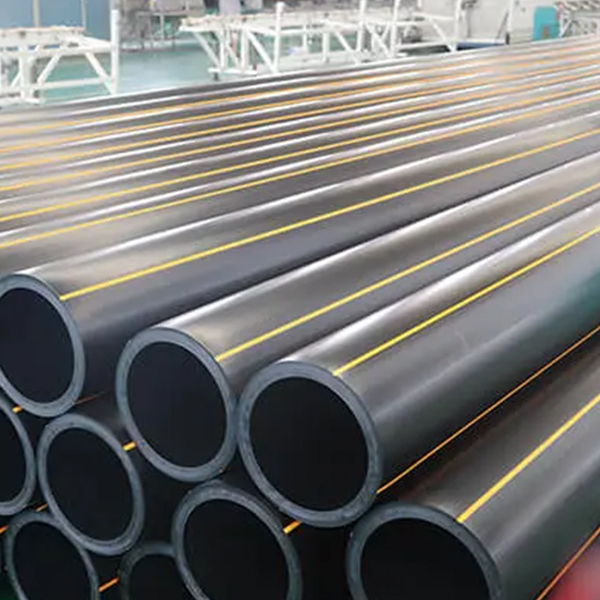

HDPE Natural Gas Pipe has good impact resistance and resistance to environmental stress cracking, and is suitable for long-term underground use.

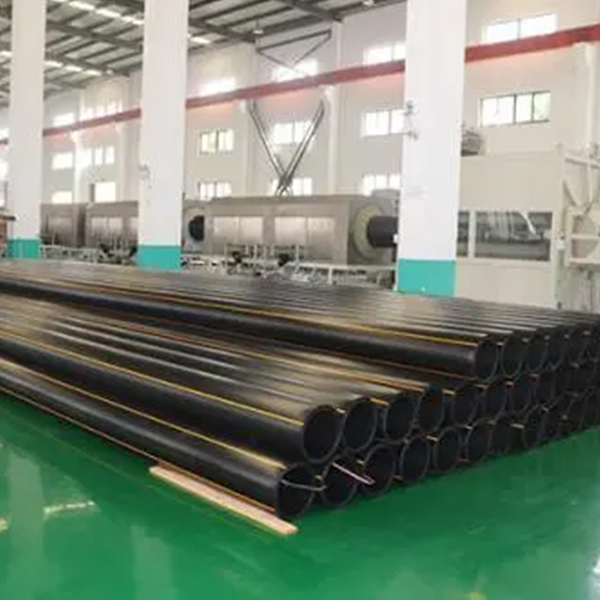

In the modern era of infrastructure development, the demand for durable, safe, and environmentally friendly piping systems has never been greater. Among the various types of plastic pipes used in gas distribution networks, HDPE Pipe for Underground Oil & Gas Gathering stands out as one of the most reliable solutions, especially for long-term underground use. With its excellent impact resistance and strong resistance to environmental stress cracking, HDPE pipe has become the preferred material for gas transportation systems around the world.

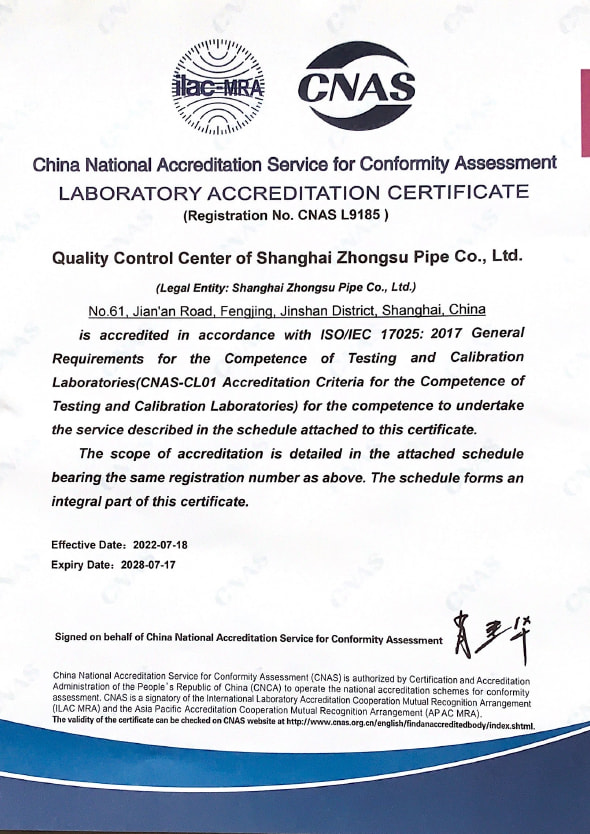

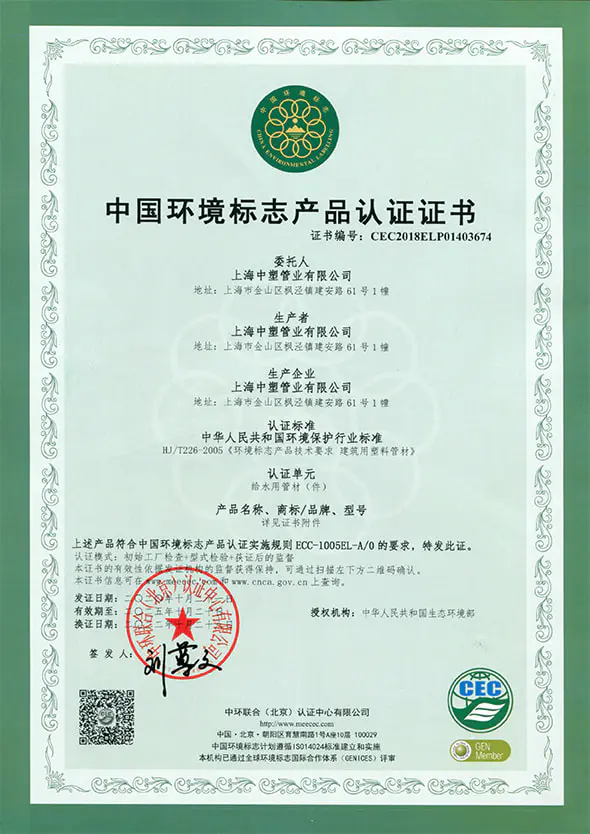

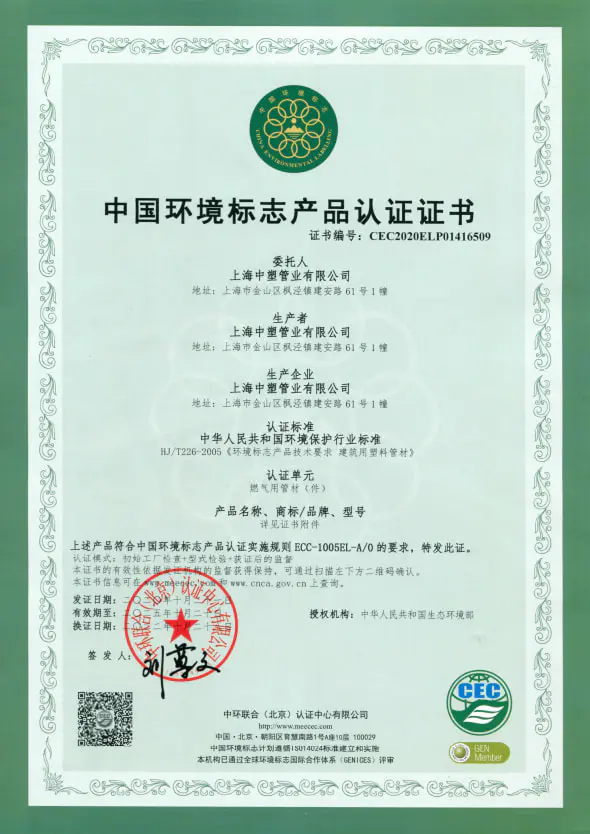

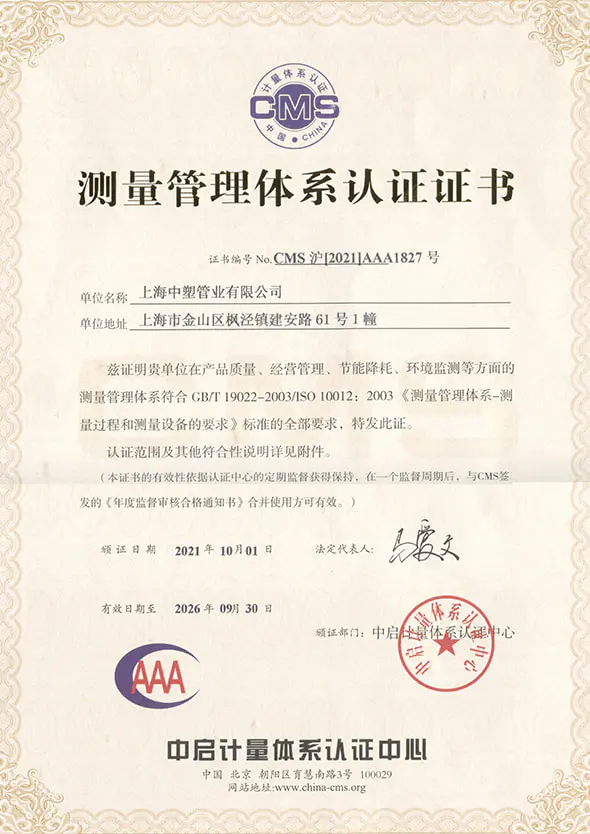

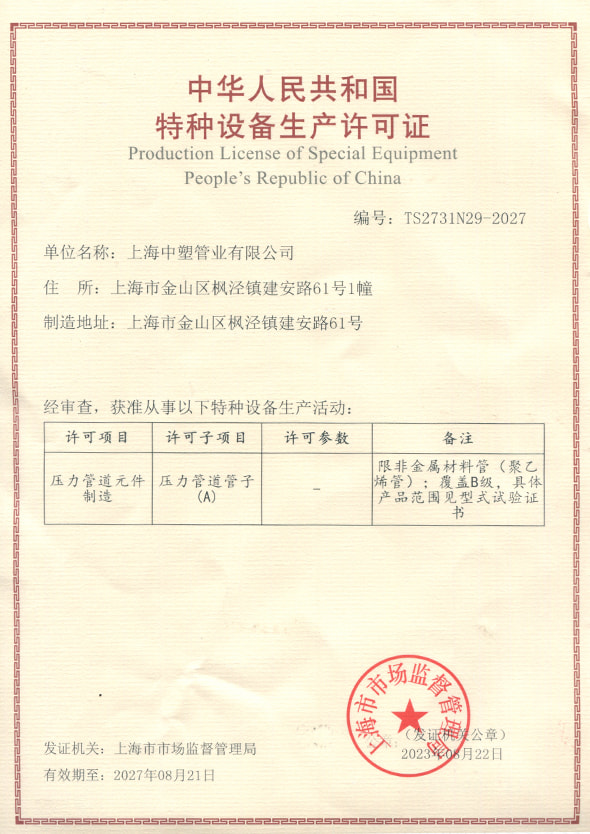

Shanghai Zhongsu Pipe Co., Ltd., established in 2004 with a registered capital of RMB 1.01 billion, is a leading manufacturer specializing in high-quality PPR and HDPE pipes and fittings. Located in Jinshan District, Shanghai, China, the company occupies an area of 70,000 square meters and operates advanced production lines that ensure high productivity and fast lead times. As a high-tech enterprise certified by ISO9001, ISO14001, and OHSAS18001, ZHSU has built a solid reputation both domestically and internationally for its commitment to quality, innovation, and sustainability.

Why HDPE Pipes Are Ideal for Natural Gas Distribution

One of the key reasons why HDPE pipes are widely used in natural gas applications is their superior mechanical properties. Unlike traditional metal pipes that are prone to corrosion and leakage, HDPE pipes offer excellent chemical resistance and do not rust or degrade when exposed to soil or moisture. This makes them particularly suitable for underground installations where maintenance and replacement can be costly and difficult.

Moreover, HDPE pipes have outstanding impact resistance , which allows them to withstand external forces such as ground movement, heavy traffic loads, and even seismic activities. This resilience ensures the integrity of the gas pipeline system under various environmental conditions.

Equally important is HDPE’s resistance to environmental stress cracking (ESCR) . Environmental stress cracking is a common cause of failure in polymeric materials, especially when they are exposed to chemicals, UV radiation, or fluctuating temperatures over long periods. HDPE pipes, however, are engineered to resist these stresses, ensuring long-term performance and safety—often exceeding 50 years in service life.

As a trusted name in the plastic pipe industry, Shanghai Zhongsu Pipe Co., Ltd. (ZHSU) plays a vital role in advancing HDPE technology for natural gas and other critical applications. The company has invested heavily in state-of-the-art production equipment and inspection systems to ensure that every HDPE pipe meets national and international standards, including ISO, GB, and ASTM specifications.

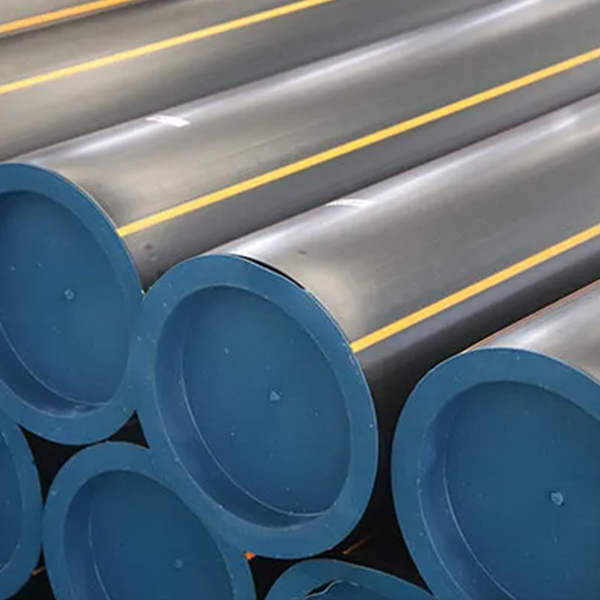

ZHSU's HDPE pipes are manufactured using 100% virgin raw materials sourced from reputable suppliers such as Borealis and top South Korean and Chinese brands. These premium materials guarantee the safety, durability, and environmental friendliness of the final products, aligning perfectly with ZHSU’s corporate mission: “to cherish every drop of water” and promote sustainable development.

The company also boasts a CNAS-certified national-level laboratory, which conducts rigorous testing on raw materials, semi-finished products, and finished goods throughout the production process. From the initial selection of resin to the final delivery of the product, every step is closely monitored to maintain consistent quality.

ZHSU offers a comprehensive range of Fusion Weld Gas Pipe, including those designed specifically for natural gas transmission. The diameter of ZHSU’s HDPE pipes can reach up to DN1200mm , making it one of the few manufacturers in China capable of producing large-diameter HDPE pipes for major infrastructure projects. This capacity enables the company to support large-scale municipal gas pipelines, industrial gas supply systems, and rural clean energy initiatives.

Beyond natural gas, ZHSU’s HDPE pipes are widely applied in:

Municipal water supply and drainage

Building internal and external plumbing

Rural drinking water safety projects

Sewage discharge and underground drainage

Nuclear power plant cooling systems

Thanks to their excellent performance and reliability, ZHSU’s products have gained popularity not only within China but also in overseas markets such as Southeast Asia, Africa, and Latin America. The company is committed to providing customers with competitive pricing , professional technical support , and timely delivery , all backed by a strong foundation of quality management and customer-oriented service.

Innovation and Corporate Values Driving Growth

At the heart of ZHSU’s success lies a clear and forward-looking development strategy: “Creating first-class enterprises, producing first-class PPR pipes & fittings, providing first-class service, establishing first-class HDPE pipes & fittings brand.” Guided by this vision, the company continuously invests in research and development, technological upgrades, and talent cultivation to maintain its leadership in the industry.

ZHSU embraces core values such as knowledge, courage, truth-seeking, and innovation , while adhering to the enterprise concept of customer-first, quality-driven, efficient management, and trustworthy cooperation . These principles not only shape the company’s internal culture but also define how it engages with global partners.

In recent years, ZHSU has actively participated in national rural drinking water safety projects and nuclear power plant construction, further expanding its application scope and market influence. The adoption of large-diameter HDPE production facilities marks a significant milestone in the company’s journey toward becoming a globally recognized brand.

HDPE natural gas pipe is an ideal choice for long-term underground use due to its excellent impact resistance, environmental stress cracking resistance, and extended service life. As a leader in the plastic pipe manufacturing industry, Shanghai Zhongsu Pipe Co., Ltd. continues to push the boundaries of innovation and quality, offering customers around the world safe, reliable, and sustainable piping solutions.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie