Nuclear Power Plant HDPE Pipe is widely used in auxiliary systems of nuclear power plants due to its excellent sealing and connection reliability.

In the field of nuclear power plant construction, ensuring safety, durability, and reliability of materials used in auxiliary systems is of paramount importance. Among the various materials employed, Nuclear Power Plant HDPE Pipes have gained widespread recognition for their superior performance in demanding environments. With its exceptional sealing capability, chemical resistance, and long-term stability, HDPE pipe has become a preferred choice for fluid transport systems in nuclear power plants, especially in non-primary but critical auxiliary systems such as cooling water supply, drainage, and fire protection.

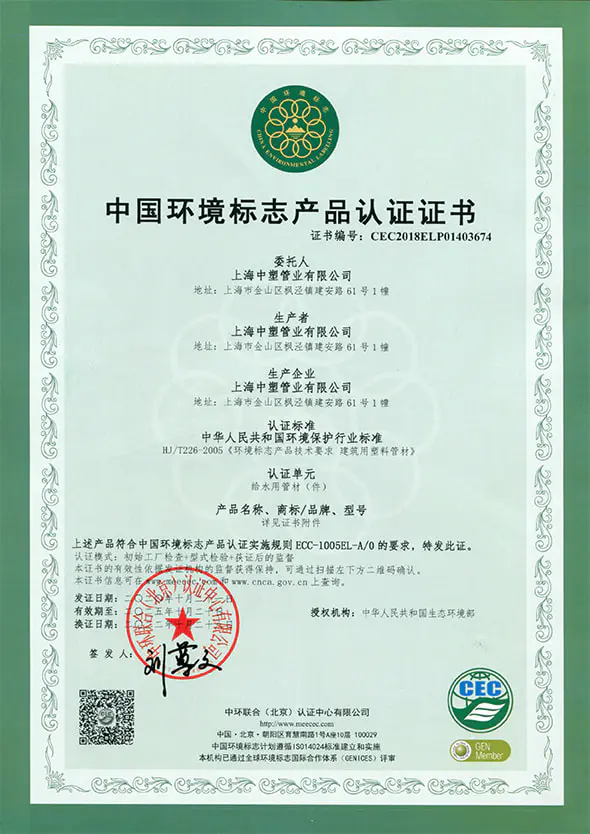

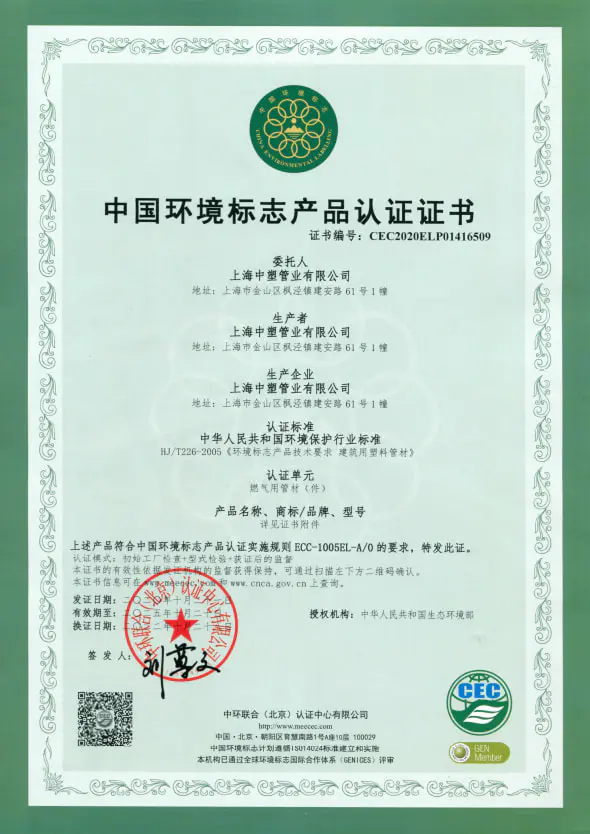

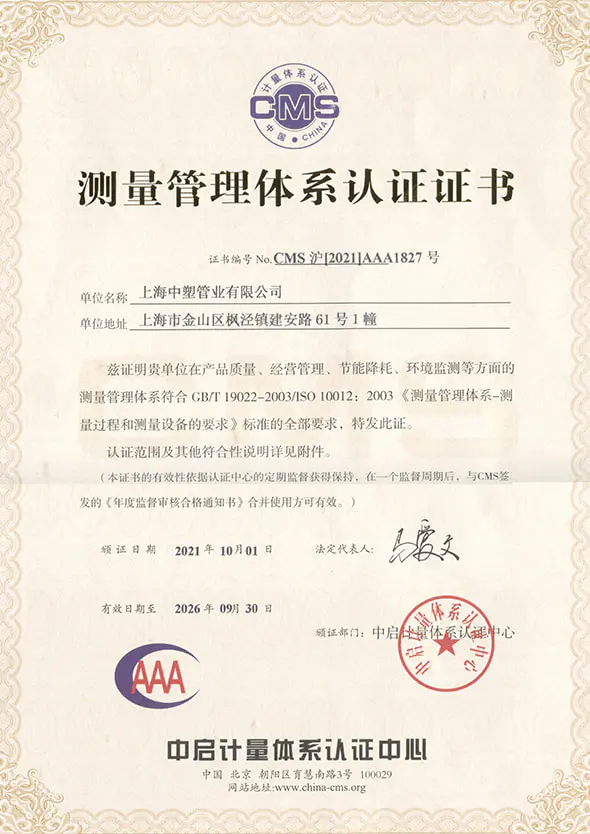

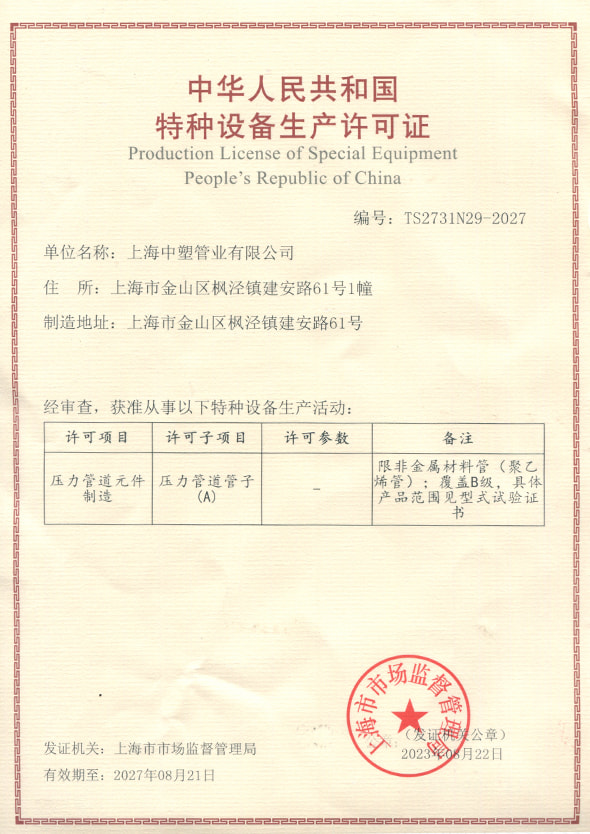

One of the leading manufacturers that have risen to meet this growing demand is Shanghai Zhongsu Pipe Co., Ltd. , a company established in 2004 with a registered capital of RMB 1.01 billion. Located in the Jinshan District of Shanghai, China, the company occupies over 70,000 square meters and has grown steadily through years of innovation and commitment to quality. As a high-tech enterprise certified by ISO9001, ISO14001, and OHSAS18001, Shanghai Zhongsu Pipe Co., Ltd. (ZHSU) has positioned itself as a reliable supplier of premium plastic piping systems, including HDPE pipes tailored for use in nuclear infrastructure.

Why HDPE Pipes are Essential for Nuclear Power Plant Applications

The auxiliary systems in nuclear power plants, though not directly involved in reactor operations, play a vital role in maintaining overall plant safety and efficiency. These include secondary cooling systems, waste treatment systems, emergency water supply lines, and fire suppression networks. In these applications, HDPE pipes offer several key advantages:

Excellent Chemical Resistance : HDPE is highly resistant to corrosion and chemical degradation, making it ideal for transporting treated or untreated water, including potentially aggressive media.

Superior Sealing Performance : The electrofusion and butt fusion jointing methods ensure leak-proof connections, which is crucial in nuclear facilities where even minor leaks can pose significant risks.

High Durability and Longevity : HDPE pipes have an expected service life of over 50 years under normal operating conditions, reducing maintenance needs and lifecycle costs.

Flexibility and Impact Resistance : HDPE's inherent flexibility allows it to absorb ground movement and seismic activity better than rigid piping systems, enhancing safety in geologically active regions.

These properties make HDPE an indispensable component in modern nuclear power plant designs, especially in countries expanding their clean energy portfolios through nuclear power.

ZHSU’s Commitment to Quality and Innovation

At the heart of Shanghai Zhongsu Pipe Co., Ltd.'s success lies its unwavering commitment to producing world-class HDPE and PPR piping solutions. The company specializes in a wide range of products, including HDPE pipes and fittings, antibacterial PP-R pipes, anti-UV PPR pipes, and PP-RCT pipes. Each product line is developed using state-of-the-art production equipment and adheres strictly to both national and international standards.

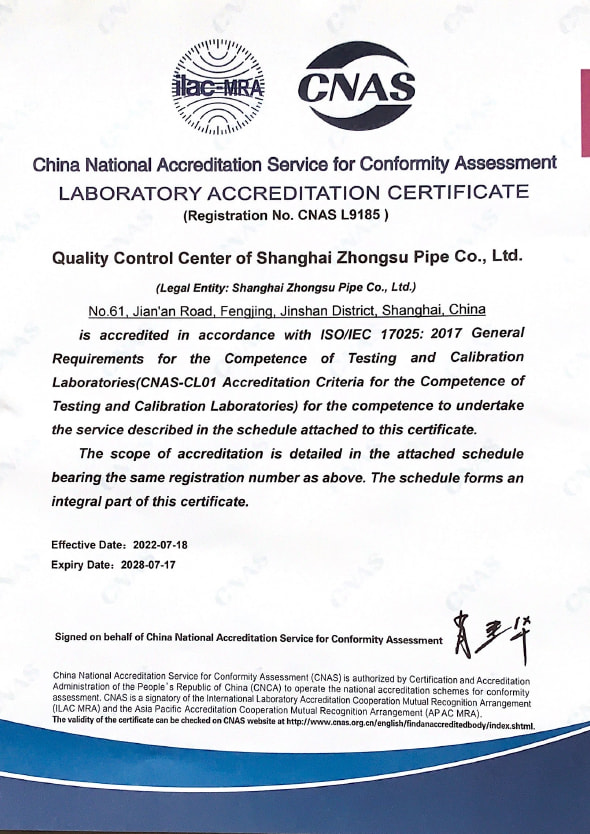

ZHSU has invested heavily in research and development, establishing a CNAS-certified national laboratory to ensure every product undergoes rigorous testing before leaving the factory. This includes pressure testing, material composition analysis, and long-term aging simulations—crucial steps when supplying products for nuclear applications.

Moreover, the company sources 100% virgin raw materials from reputable suppliers such as Borealis and leading South Korean and Chinese brands, guaranteeing environmental friendliness and product safety. ZHSU believes that "every drop of water counts" and views water conservation and sustainable development as integral parts of its corporate mission.

Meeting the Demands of Large-Scale Projects

As part of its strategic vision to become a first-class brand in the global piping industry, ZHSU has continuously upgraded its production capabilities to meet the evolving demands of large-scale infrastructure projects, including those related to nuclear energy.

One notable advancement is the company's ability to produce Nuclear Power Plant HDPE Pipe with diameters up to DN1200mm. This capacity places ZHSU among the few manufacturers in China capable of supplying large-diameter HDPE pipes, which are essential for major water conveyance systems within nuclear facilities. Such pipes are commonly used in primary and secondary cooling water circuits, drainage systems, and emergency water storage tanks.

This technological leap was driven by ZHSU's participation in nationwide rural drinking water safety projects and collaborations with nuclear power plant developers. By aligning with the national push toward green and sustainable energy, ZHSU has positioned itself at the forefront of the nuclear support infrastructure supply chain.

Global Reach and Market Recognition

Beyond domestic markets, ZHSU’s HDPE pipes and fittings have gained popularity in Southeast Asia, Africa, Latin America, and other regions where infrastructure development is booming. The company's export-oriented strategy, combined with competitive pricing and professional after-sales service, has earned it a strong reputation abroad.

Within China, ZHSU has been recognized as a “Shanghai Famous Brand Product,” “Shanghai High-Tech Enterprise,” and “Shanghai Famous Trademark.” These accolades reflect the market’s trust in the company’s technical expertise and consistent delivery of high-quality products.

For nuclear power plant developers, this means working with a supplier that understands the unique challenges of nuclear environments and is equipped to deliver customized piping solutions that meet exacting specifications.

As the global demand for clean and sustainable energy continues to rise, nuclear power remains a critical component of many countries’ energy strategies. The auxiliary systems within nuclear power plants require materials that offer unmatched reliability, longevity, and safety—qualities that HDPE pipes supplied by companies like Shanghai Zhongsu Pipe Co., Ltd. exemplify.

With its robust product portfolio, advanced manufacturing capabilities, and dedication to excellence, ZHSU is well-positioned to support the next generation of nuclear infrastructure. Whether in municipal water supply systems or the complex pipelines of a nuclear facility, ZHSU remains committed to delivering solutions that protect people, preserve resources, and promote sustainable development.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie