Material Properties of PPR Pipe Fittings and Their Importance in Pipe Engineering

In the field of modern piping systems, PPR pipe fittings have become essential components due to their excellent performance, durability, and adaptability. As one of China’s leading manufacturers of high-quality plastic piping solutions, Shanghai Zhongsu Pipe Co., Ltd has played a pivotal role in advancing the application of PPR pipes and fittings across various industries.

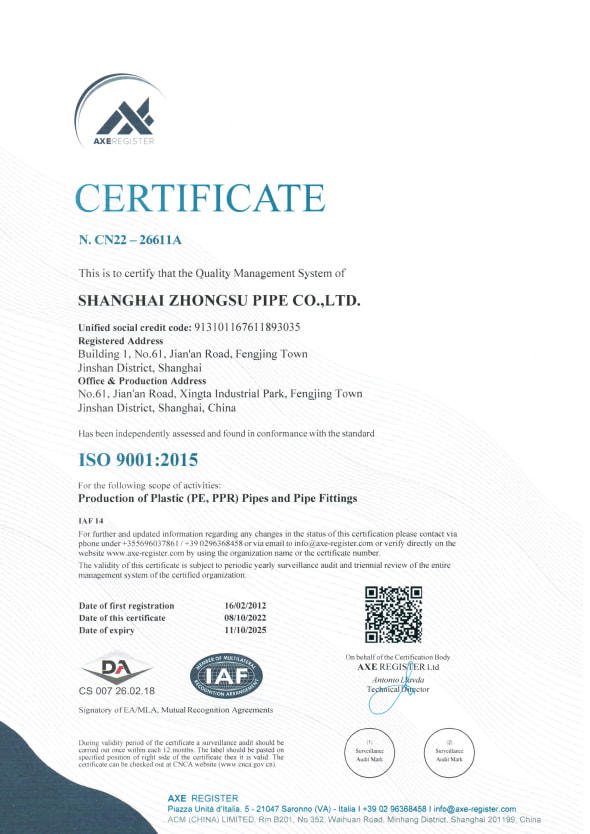

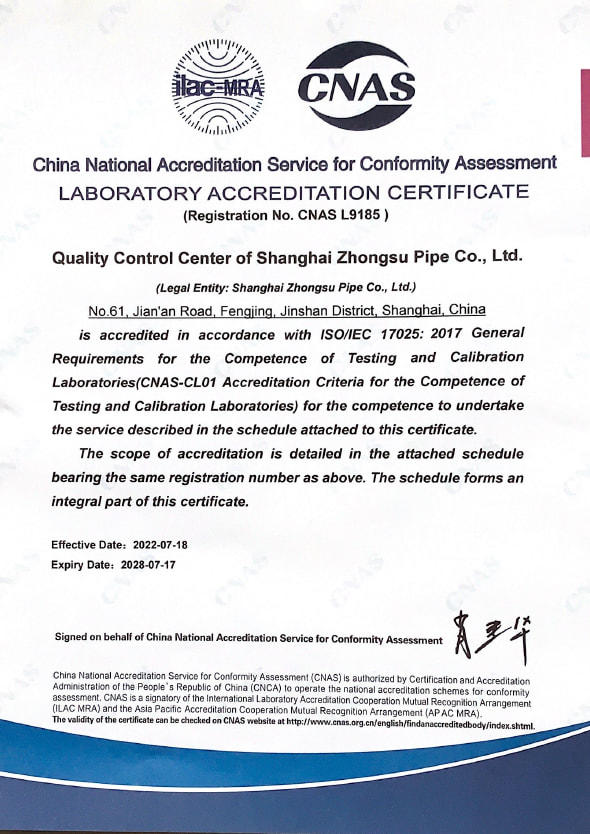

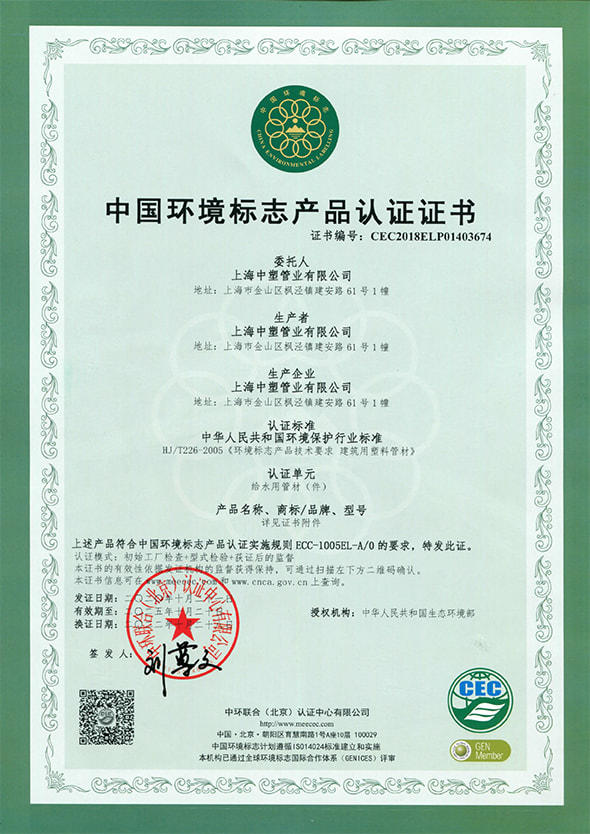

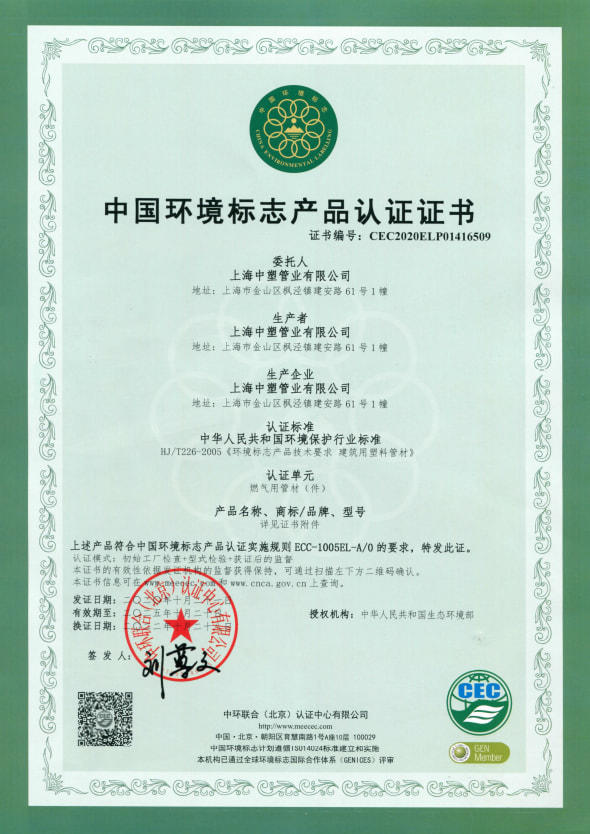

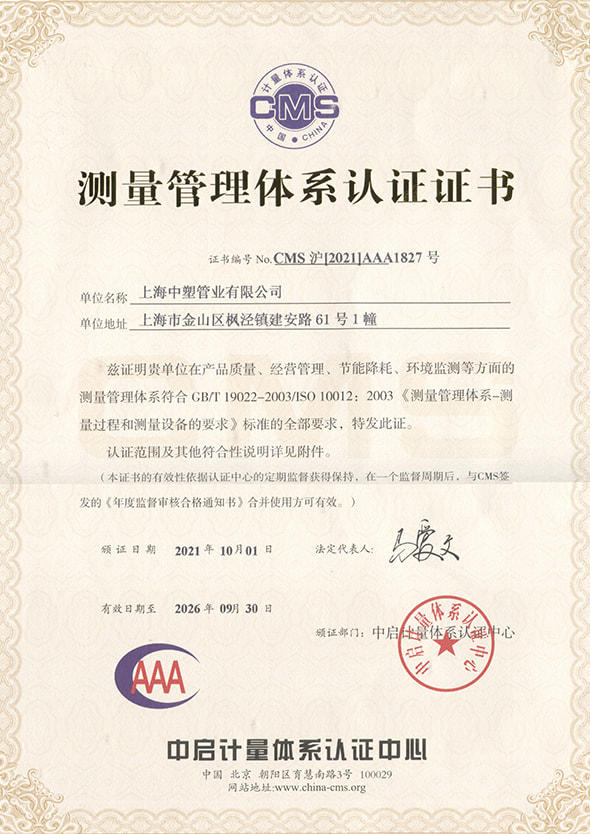

Established in 2004 with a registered capital of RMB 1.01 billion, Shanghai Zhongsu Pipe Co., Ltd is located in the Jinshan District of Shanghai, covering an area of 70,000 square meters. The company specializes in producing a wide range of products including PPR pipes and fittings, antibacterial PPR pipes, anti-UV PPR pipes, PP-RCT pipes, HDPE pipes, and related fittings. With advanced production lines and a CNAS-certified national laboratory, ZHSU ensures that every product meets stringent quality standards. The company uses 100% virgin raw materials from reputable brands such as Borealis and domestic suppliers, guaranteeing environmental friendliness and safety—core values that align with its mission: “cherishing every drop of water.”

Understanding PPR Material Properties

PPR, or Polypropylene Random copolymer, is a thermoplastic polymer known for its excellent thermal resistance, chemical stability, and mechanical strength. These properties make PPR fittings ideal for hot and cold water supply systems, especially in residential, commercial, and industrial applications.

One of the key material properties of PPR fittings is their ability to withstand high temperatures—up to 95°C for extended periods without deformation. This makes them suitable for use in underfloor heating systems, potable water distribution, and other high-temperature applications. Additionally, PPR fittings exhibit low thermal expansion compared to metal alternatives, reducing stress on the piping system and minimizing leakage risks.

Another important characteristic is their excellent corrosion resistance. Unlike traditional metallic piping systems, which are prone to rust and scale buildup, PPR fittings do not react with water or chemicals commonly found in municipal water supplies. This not only extends the service life of the system but also ensures consistent water quality and flow efficiency.

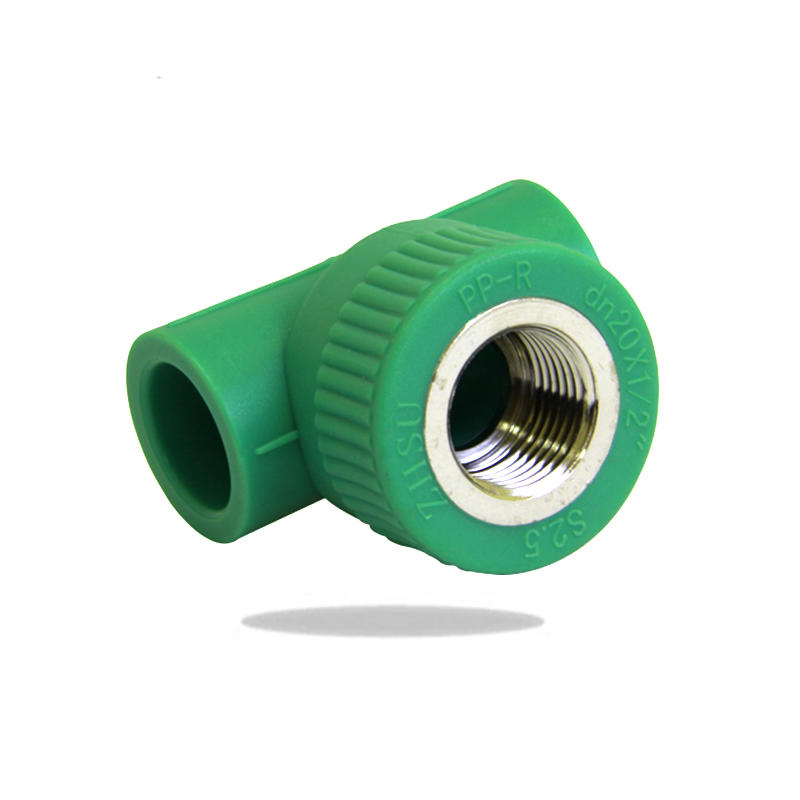

Moreover, PPR fittings are lightweight and easy to install using heat fusion techniques, eliminating the need for additional sealing materials such as gaskets or adhesives. This contributes to faster installation times and lower labor costs, making PPR systems highly cost-effective over their lifecycle.

Importance of PPR Fittings in Pipe Engineering

In pipe engineering, the choice of materials significantly affects the reliability, safety, and longevity of the entire system. PPR fittings play a crucial role in ensuring leak-free connections, structural integrity, and long-term performance of piping networks.

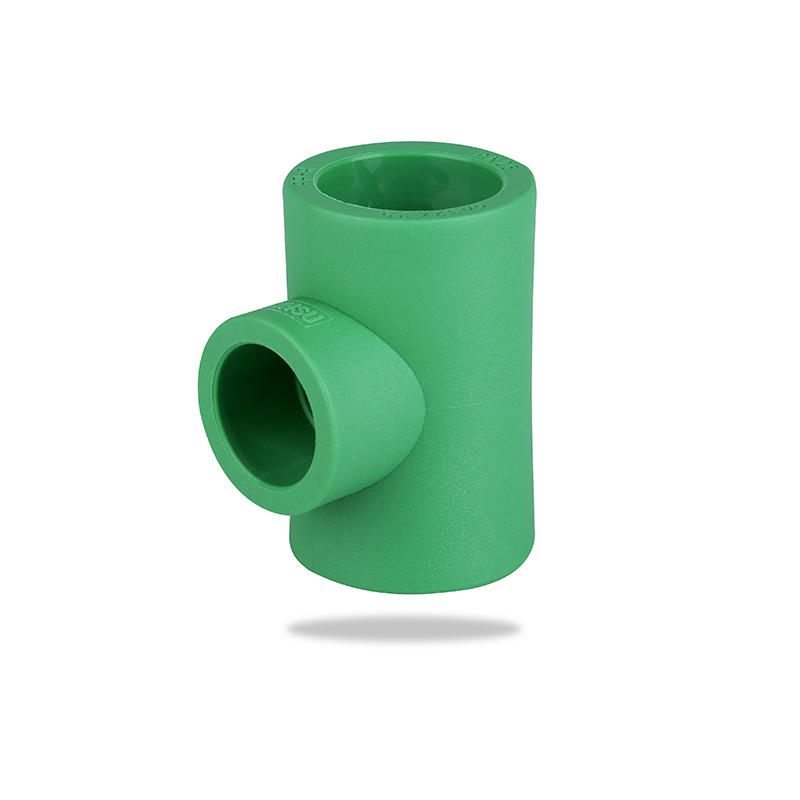

For instance, in building water supply and drainage systems, PPR Pipe Fittings provide seamless integration between straight pipes and directional changes, branch-offs, and terminations. Their compatibility with both rigid and flexible layouts allows engineers to design complex systems tailored to specific architectural and functional requirements.

Shanghai Zhongsu Pipe Co., Ltd emphasizes strict adherence to international standards such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and OHSAS 18001 (Occupational Health and Safety). This ensures that all PPR fittings produced by ZHSU meet or exceed the required technical specifications and safety benchmarks.

Furthermore, ZHSU has developed specialized variants of PPR fittings, including antibacterial PPR and anti-UV PPR pipes, catering to niche markets where hygiene and outdoor durability are critical. These innovations reflect the company’s commitment to continuous improvement and customer-centric product development.

Applications and Global Reach

ZHSU's comprehensive product system includes PP-R water supply pipes, antibacterial PP-R pipes, PP-RCT pipes, HDPE water supply and drainage pipes, and corresponding fittings. These products serve diverse applications such as municipal water supply, large-diameter underground drainage, sewage discharge, and rural water network transformation projects.

The company has also expanded its capabilities to meet the demands of large-scale infrastructure projects. For example, ZHSU has invested in large-diameter PE production facilities to support national rural drinking water safety initiatives and nuclear power plant construction. Currently, the company can produce PE pipes with diameters up to DN1200mm, positioning it among the few Chinese manufacturers capable of such large-scale production.

With exports reaching Southeast Asia, Africa, Latin America, and beyond, ZHSU’s reputation for reliable quality, competitive pricing, and professional service continues to grow. The company operates under core values such as "customer first, quality foremost, management efficiency, reputation, and sincerity," reinforcing its position as a trusted partner in global pipe engineering.

The material properties of PPR pipe fittings—such as high thermal resistance, corrosion resistance, ease of installation, and long service life—are fundamental to their success in modern pipe engineering. Companies like Shanghai Zhongsu Pipe Co., Ltd exemplify how innovation, quality control, and strategic development can elevate the performance and sustainability of piping systems worldwide.

As infrastructure demands continue to evolve, the importance of selecting high-performance materials like PPR will only increase. With its dedication to knowledge, courage, truth-seeking, and innovation, ZHSU remains committed to pushing the boundaries of what is possible in the world of pipe engineering, delivering value to customers and contributing to a safer, more sustainable future.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português