PPR Coupling stabilizes water flow and reduces leakage risk in floor heating systems

In modern building systems, underfloor heating has become an increasingly popular solution for its energy efficiency, comfort, and space-saving advantages. However, the performance of such systems heavily depends on the reliability and quality of the piping components used. One critical component that plays a key role in ensuring system integrity is the PPR coupling .

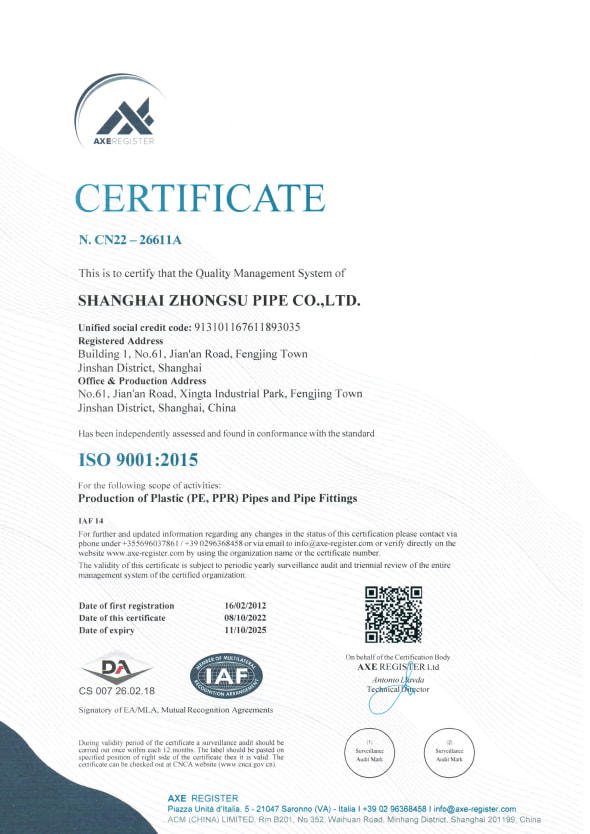

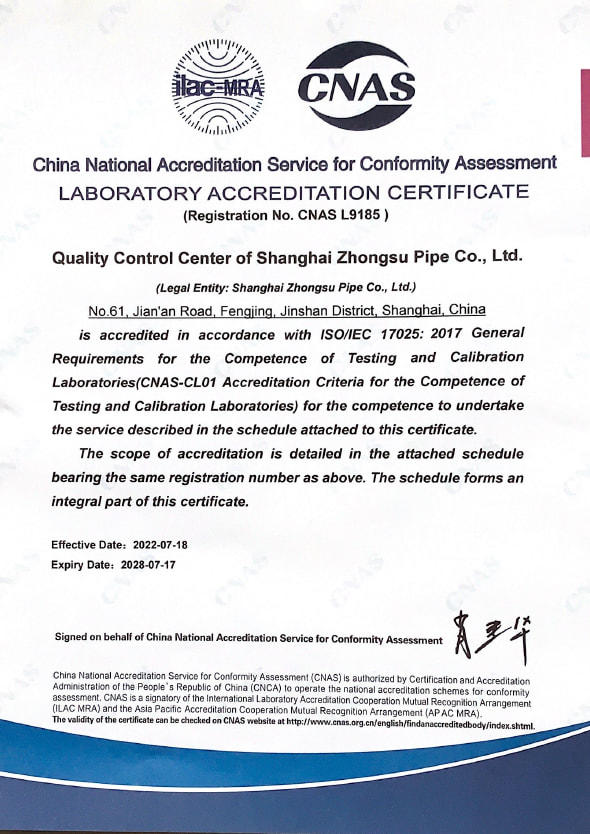

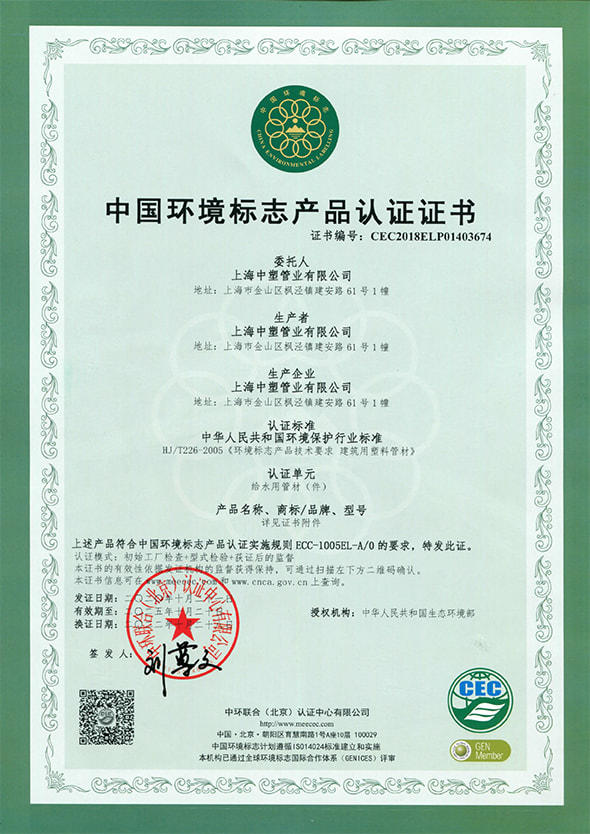

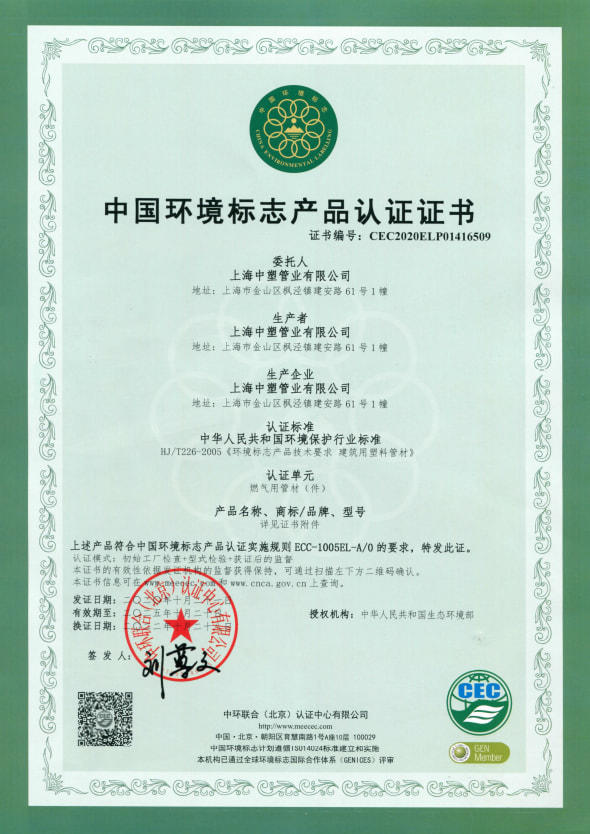

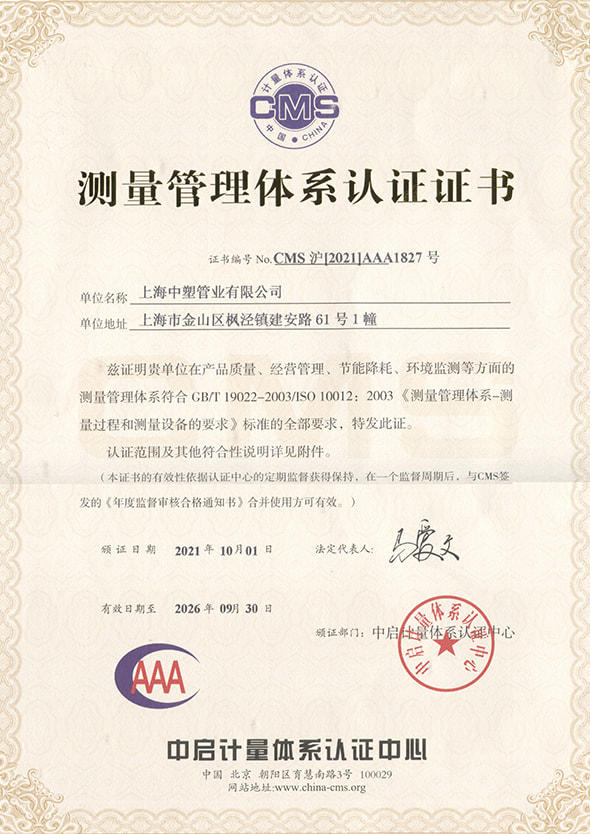

Shanghai Zhongsu Pipe Co., Ltd., established in 2004 with a registered capital of RMB 1.01 billion, is a leading manufacturer specializing in high-quality PPR pipes and fittings. Located in Shanghai’s Jinshan District and occupying over 70,000 square meters, ZHSU has grown steadily by adhering to its development strategy: “creating first-class enterprises, producing first-class PPR pipes & fittings, providing first-class service, establishing first-class HDPE pipes & fittings brand.” With advanced production lines, strict quality control, and international certifications including ISO9001, ISO14001, and OHSAS18001, ZHSU has earned recognition as a "Shanghai Famous Brand Product," "Shanghai High-Tech Enterprise," and "Shanghai Famous Trademark."

The Role of PPR Couplings in Floor Heating Systems

Floor heating systems rely on a network of pipes embedded within the floor structure to circulate hot water, thereby radiating heat evenly across the room. Given the enclosed nature of these systems, any leakage or inefficiency can result in significant damage and costly repairs. Therefore, the choice of pipe connections—particularly couplings—is crucial.

PPR couplings are specifically designed to connect two sections of PPR pipes through a heat fusion process. This method creates a seamless and durable joint that resists thermal expansion and contraction, which are common in heated environments. Unlike traditional metal fittings that may corrode or loosen over time, PPR couplings offer long-term stability and leak-proof performance.

ZHSU's PPR couplings are produced using 100% virgin raw materials from reputable global suppliers such as Borealis and South Korea, ensuring both environmental safety and mechanical strength. These materials are non-toxic, corrosion-resistant, and capable of withstanding temperatures up to 95°C, making them ideal for use in underfloor heating systems.

How PPR Couplings Improve System Performance

1. Stable Water Flow Distribution

In floor heating systems, maintaining a consistent and stable flow of water throughout the entire loop is essential for uniform heating. Any restriction or turbulence in the flow can lead to uneven temperature distribution, reduced efficiency, and increased energy consumption.

ZHSU’s PPR couplings are engineered with smooth internal surfaces that minimize friction and pressure drop. Their precise dimensions ensure proper alignment between connected pipes, promoting laminar flow and reducing the risk of flow obstruction. As a result, the heating system operates more efficiently, consuming less energy while delivering superior comfort.

2. Reduced Risk of Leaks

Leakage is one of the most serious concerns in closed-loop heating systems. Traditional threaded or compression fittings are prone to loosening due to vibration, thermal stress, or improper installation. In contrast, PPR couplings are fused directly to the pipe, creating a monolithic structure with no weak points.

ZHSU employs high-tech automated production lines and advanced inspection equipment to ensure each coupling meets stringent quality standards. The company’s CNAS-certified national laboratory conducts regular tests on material properties, tensile strength, and sealing performance, guaranteeing every product performs reliably under real-world conditions.

Moreover, because PPR material is inherently resistant to chemical corrosion and scale buildup, the risk of degradation over time is significantly reduced. This longevity not only enhances system reliability but also lowers maintenance costs.

3. Compatibility with Modern Installation Techniques

Modern underfloor heating installations often involve complex layouts with multiple loops and directional changes. PPR couplings provide flexibility in design and ease of installation, allowing plumbers to create customized configurations without compromising structural integrity.

ZHSU offers a wide range of PPR couplings in various sizes and types to suit different system requirements. Whether it’s straight connections, branch-offs, or transition fittings, the company provides comprehensive solutions tailored for residential, commercial, and industrial applications.

Additionally, ZHSU’s commitment to innovation has led to the development of antibacterial PPR pipes and fittings, which are especially valuable in hygienic environments such as hospitals and schools. These products inhibit bacterial growth inside the piping system, further enhancing safety and health standards.

Environmental Responsibility and Sustainable Development

As part of its corporate mission, ZHSU emphasizes environmental protection and sustainable resource utilization. Every product is manufactured with eco-friendly materials and processes that minimize waste and energy consumption. The company actively participates in national initiatives such as rural drinking water safety projects and nuclear power plant infrastructure development, contributing to the improvement of public welfare and environmental sustainability.

ZHSU’s large-diameter PE production capabilities, with a maximum diameter reaching DN1200mm, reflect its technological leadership and capacity to meet diverse market demands. While this technology primarily serves municipal water supply and drainage systems, it underscores the company’s ability to innovate and scale according to evolving industry needs.

Global Reach and Market Recognition

ZHSU’s products have gained widespread acceptance both domestically and internationally. In addition to dominating the Chinese market, the company exports to Southeast Asia, Africa, Latin America, and other regions. Its reputation for quality, reliability, and professional service has made it a trusted partner for engineers, contractors, and end-users alike.

The company continues to invest in research and development, striving to exceed current industry standards. Guided by its core values of “knowledge, courage, truth-seeking, and innovation,” ZHSU remains committed to advancing plastic piping technology and offering cutting-edge solutions for modern construction challenges.

PPR couplings play a vital role in stabilizing water flow and minimizing leakage risks in underfloor heating systems. Shanghai Zhongsu Pipe Co., Ltd. stands out as a premier provider of these essential components, combining technical excellence, rigorous quality control, and environmental responsibility.

With its extensive product line, international certifications, and customer-centric philosophy, ZHSU ensures that every project benefits from reliable, safe, and efficient piping solutions. As the demand for underfloor heating continues to grow worldwide, ZHSU is well-positioned to support this trend with innovative products that meet the highest standards of performance and sustainability.

For professionals in the construction and plumbing industries, choosing ZHSU means choosing peace of mind—knowing that every coupling, pipe, and fitting is designed to last, perform flawlessly, and contribute to a safer, greener future.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português