Construction environment and process requirements that need to be paid attention to when installing PPR Cross

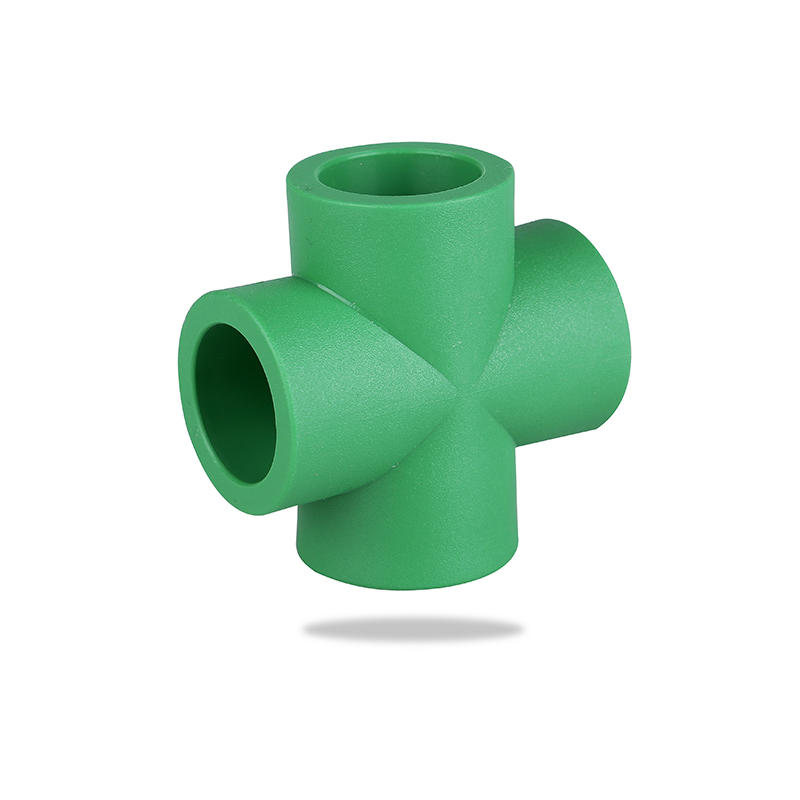

PPR materials have gained widespread popularity due to their excellent thermal resistance, corrosion resistance, and environmental safety. Among various fittings used in these systems, the PPR cross fitting plays a crucial role in water distribution layouts. However, the installation of PPR cross fittings requires meticulous attention to environmental conditions and construction processes to ensure durability, efficiency, and safety. This article discusses the key factors to consider during installation, based on industry experience and best practices, with reference to Shanghai Zhongsu Pipe Co., Ltd (ZHSU), one of China's leading manufacturers in plastic piping solutions.

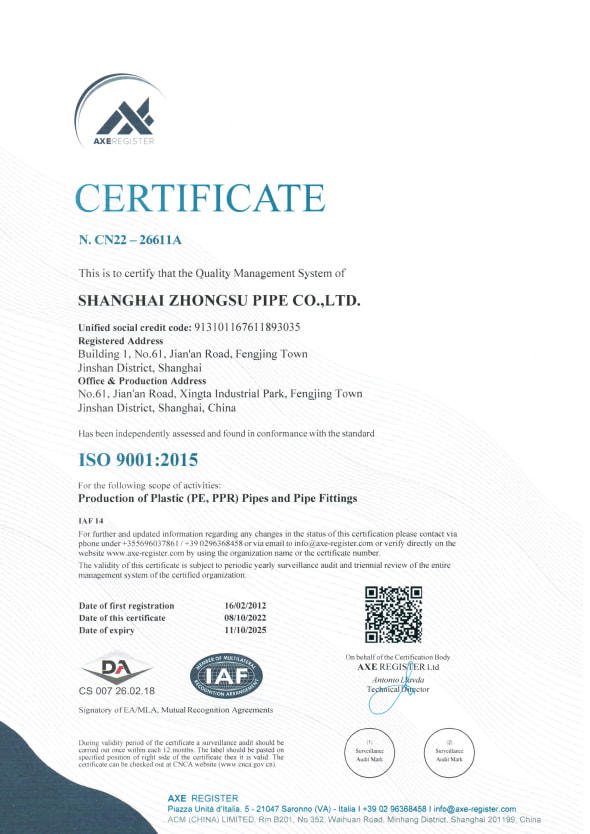

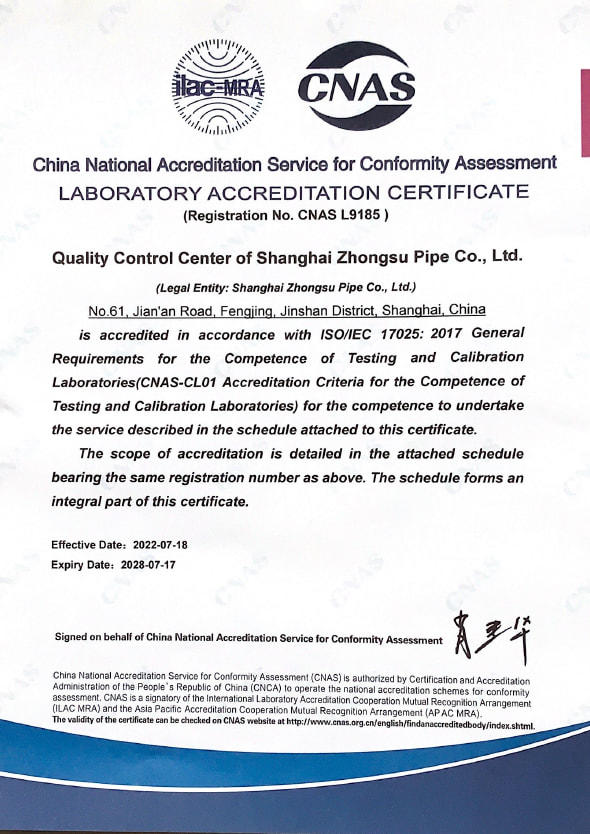

Established in 2004, Shanghai Zhongsu Pipe Co., Ltd (ZHSU) is located in Jinshan District, Shanghai, and occupies an area of 70,000 square meters. With a registered capital of 1.01 billion RMB, ZHSU specializes in the production of PPR pipe and fittings, including antibacterial and anti-UV PPR products, as well as PP-RCT and HDPE pipe systems. The company adopts advanced production lines and operates a CNAS-accredited national laboratory to ensure the highest standards of product quality.

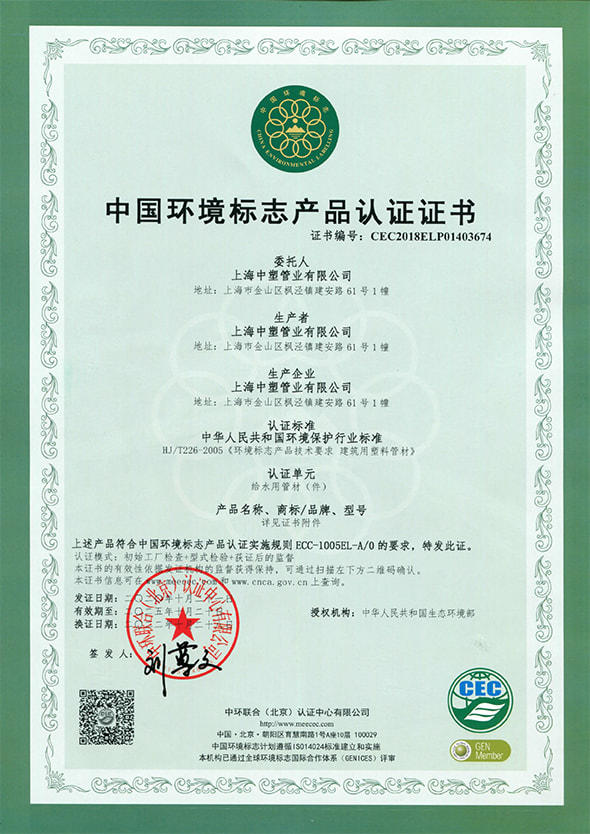

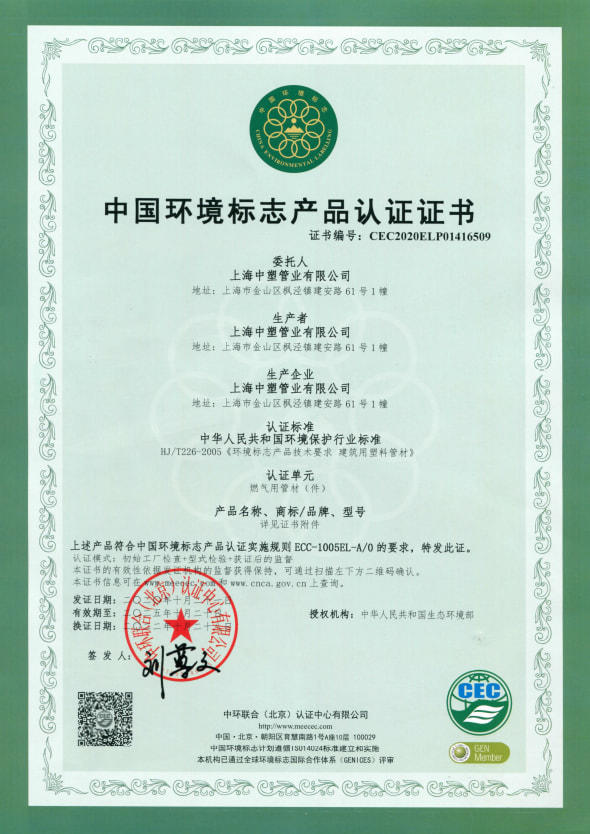

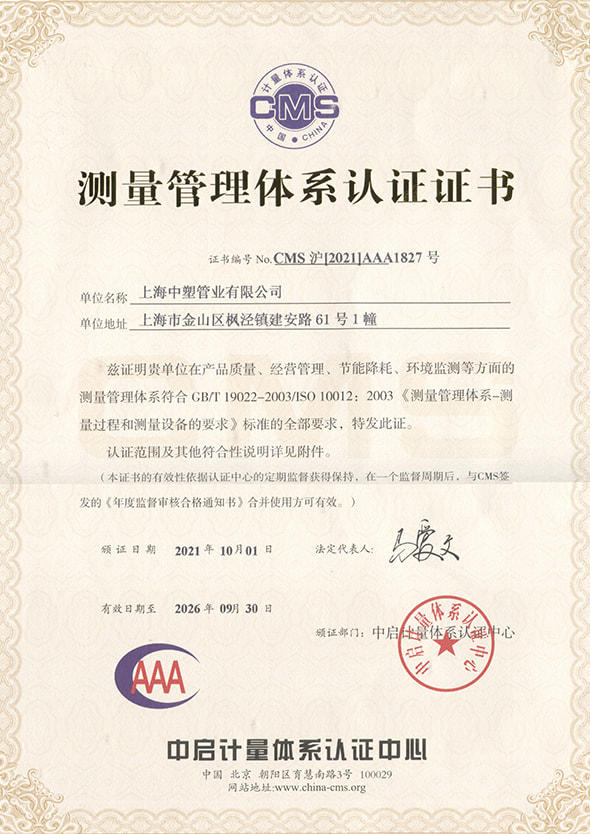

ZHSU is committed to using 100% virgin raw materials from globally recognized sources such as Borealis and South Korea, ensuring that its products are safe, environmentally friendly, and durable. The company holds certifications including ISO9001, ISO14001, and OHSAS18001, and is recognized as a “Shanghai High-Tech Enterprise” and a “Shanghai Famous Brand.”

Environmental Conditions for PPR Cross Installation

To guarantee the long-term performance of PPR cross fittings, it is essential to maintain a suitable construction environment. Based on industry knowledge and ZHSU’s product application standards, the following environmental conditions are recommended:

Temperature Control:

The ideal ambient temperature for installing PPR cross fittings is between 5°C and 35°C. Extreme cold can cause the pipe to become brittle, while excessive heat may soften the material, affecting fusion quality.

Clean and Dry Conditions:

The installation site should be free from dust, moisture, and oil to prevent contamination during the fusion process. A clean environment is vital for ensuring strong, leak-free joints.

UV Protection:

While ZHSU manufactures anti-UV PPR pipes, it is still recommended that PPR fittings and pipes be protected from prolonged direct sunlight during installation and storage to maintain material integrity.

Stable Support:

Ensure that all components, including the PPR cross, are adequately supported during installation to prevent undue stress on joints, especially during the heating and cooling phases.

Installation Process Requirements

ZHSU emphasizes adherence to national and international construction standards during installation. Below are the critical process requirements for the installation of PPR cross fittings:

Proper Cutting and Chamfering:

Use specialized pipe cutters to achieve clean, straight pipe ends. Chamfering should be performed to remove burrs and create a smooth insertion end, which helps ensure a proper weld.

Correct Heating Time:

Using an electric fusion welding tool, the pipe and PPR cross fitting should be heated for the manufacturer-recommended duration—typically around 5 seconds per 20mm of pipe diameter. Overheating can degrade material quality, while underheating may lead to weak joints.

Quick and Steady Joining:

After heating, quickly insert the pipe into the PPR cross fitting without rotation, and hold firmly until the joint cools down. ZHSU’s precision-engineered fittings ensure a snug fit for optimal fusion.

Inspection and Pressure Testing:

After installation, a thorough inspection should be conducted for visible flaws. ZHSU recommends pressure testing the system to identify any weak points before full commissioning.

Avoid Mechanical Stress:

Post-installation, ensure that the piping system is free from external stress or misalignment. Secure the system with proper clamps and supports as specified by ZHSU guidelines.

Safety and Compliance

As part of its mission to “cherish every drop of water,” ZHSU advocates for safe and sustainable construction practices. Installers should wear protective gloves and goggles during hot-melt operations. Additionally, all personnel should be trained in accordance with ISO standards to handle equipment and fittings responsibly.

ZHSU’s PPR products are widely used in residential buildings, municipal infrastructure, and rural water supply networks. Their durability and safety make them suitable for critical applications such as nuclear power facilities and large-scale water distribution systems, with product diameters reaching up to DN1200mm.

Installing PPR cross fittings demands attention to environmental factors and strict adherence to standardized procedures. Shanghai Zhongsu Pipe Co., Ltd sets a benchmark in the industry through its commitment to quality, innovation, and sustainability. By following ZHSU’s product-specific guidelines and maintaining a clean, controlled work environment, construction teams can ensure the long-lasting performance of PPR piping systems. With the guiding principles of “knowledge, courage, truth-seeking, and innovation,” ZHSU continues to provide first-class products and services that support safe and efficient infrastructure development worldwide.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português