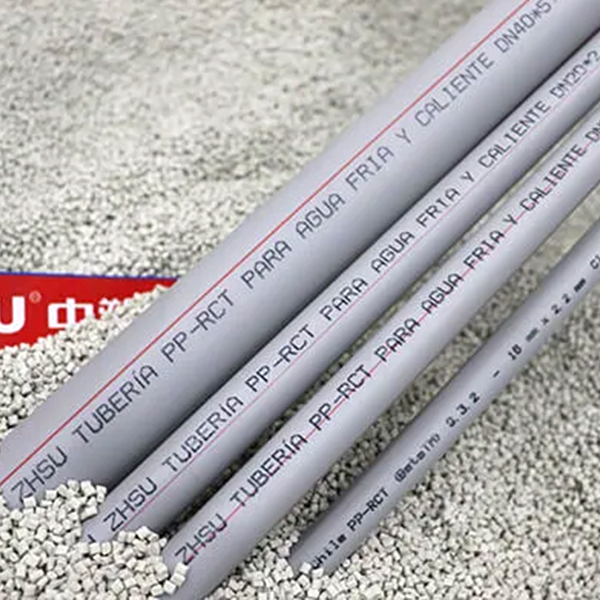

PP-RCT Pipe has higher pressure resistance and long-term thermal stability, suitable for high-temperature water transportation systems

In the modern construction and infrastructure industry, the demand for durable, safe, and high-performance piping systems is ever-increasing. Among various types of plastic pipes, PP-RCT pipe has emerged as a revolutionary product due to its excellent mechanical properties, pressure resistance, and long-term thermal stability. These characteristics make it particularly suitable for high-temperature water transportation systems such as hot water supply, radiant heating, and industrial applications.

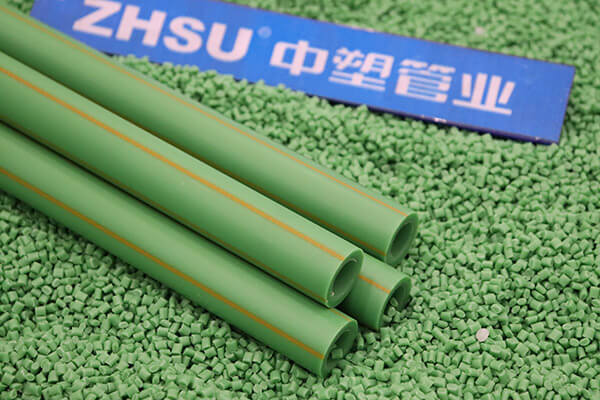

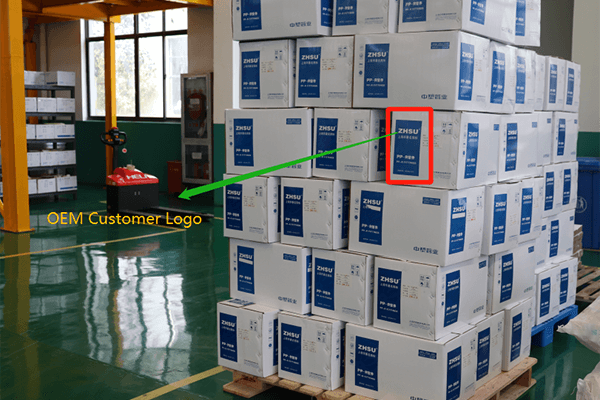

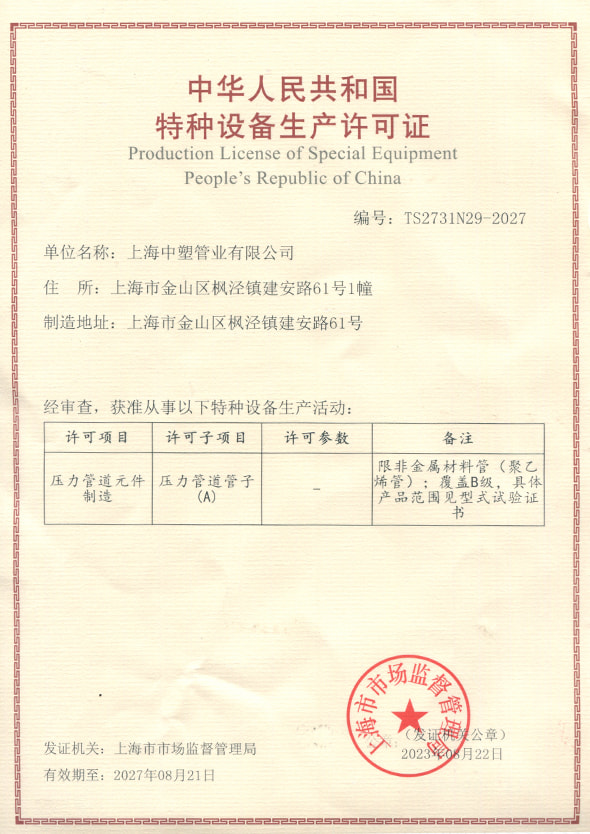

Shanghai Zhongsu Pipe Co., Ltd., established in 2004 with a registered capital of RMB 1.01 billion, is a leading manufacturer specializing in high-quality plastic piping systems including PP-R, antibacterial PP-R, anti-UV PP-R, PP-RCT, and HDPE pipes and fittings. Located in Jinshan District, Shanghai, China, ZHSU occupies an area of 70,000 square meters and has built itself into a first-class enterprise in the industry through continuous innovation, strict quality control, and customer-centric service.

The Technical Advantages of PP-RCT Pipes

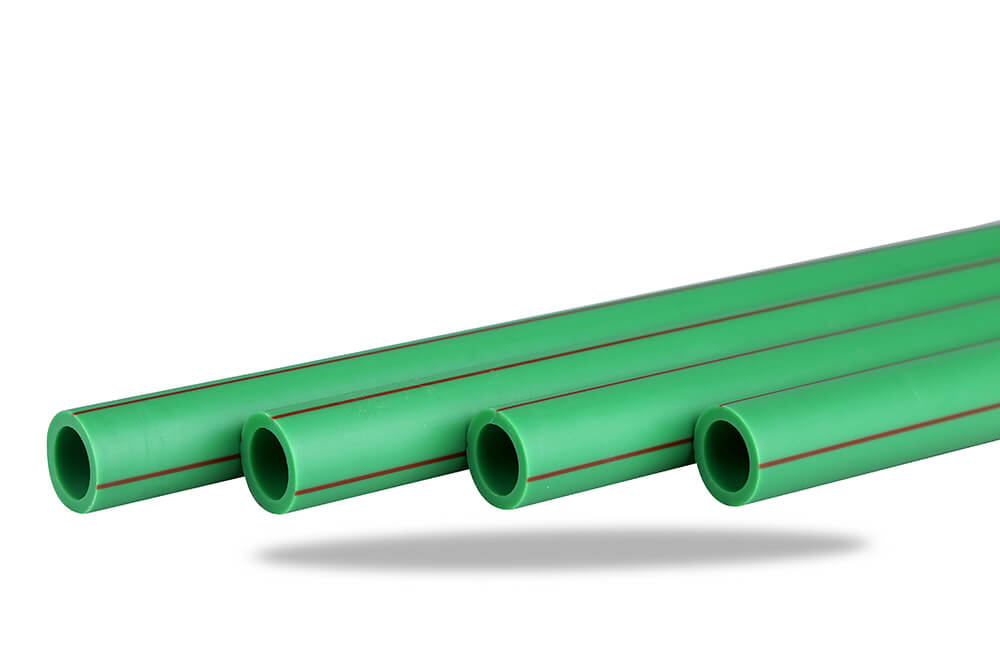

PP-RCT technology represents a significant advancement over traditional PP-R (Polypropylene Random) pipes. The key difference lies in the molecular structure and crystallinity of the material. PP-RCT is produced using a special polymerization process that enhances the transition temperature of the material, resulting in superior pressure resistance even at elevated temperatures.

Standard PP-R pipes are typically rated for a maximum operating temperature of 70°C under standard conditions. However, PP-RCT pipes can maintain their structural integrity and pressure-bearing capacity at temperatures up to 95°C over extended periods. This makes them ideal for use in central heating systems, district heating networks, and other applications where long-term exposure to high-temperature water is inevitable.

Moreover, PP-RCT pipes exhibit excellent creep resistance, meaning they do not deform or fail under constant stress over time. This ensures the safety and reliability of the entire piping system, especially in environments where the pipes may be subjected to both high pressure and high temperature simultaneously.

Why Choose PP-RCT from ZHSU?

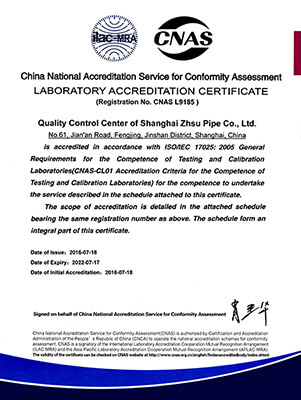

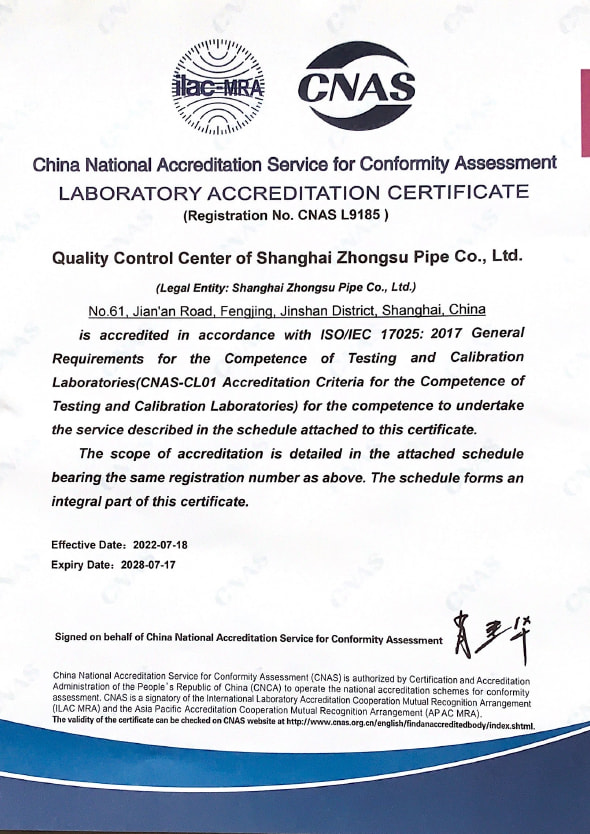

At Shanghai Zhongsu Pipe Co., Ltd., the production of PP-RCT pipes follows international standards and employs advanced manufacturing technologies. The company has invested heavily in state-of-the-art production lines and inspection equipment, ensuring that each batch of products meets stringent quality requirements. With CNAS-certified national laboratory facilities on-site, ZHSU conducts rigorous testing on raw materials and finished products, guaranteeing consistent performance and safety.

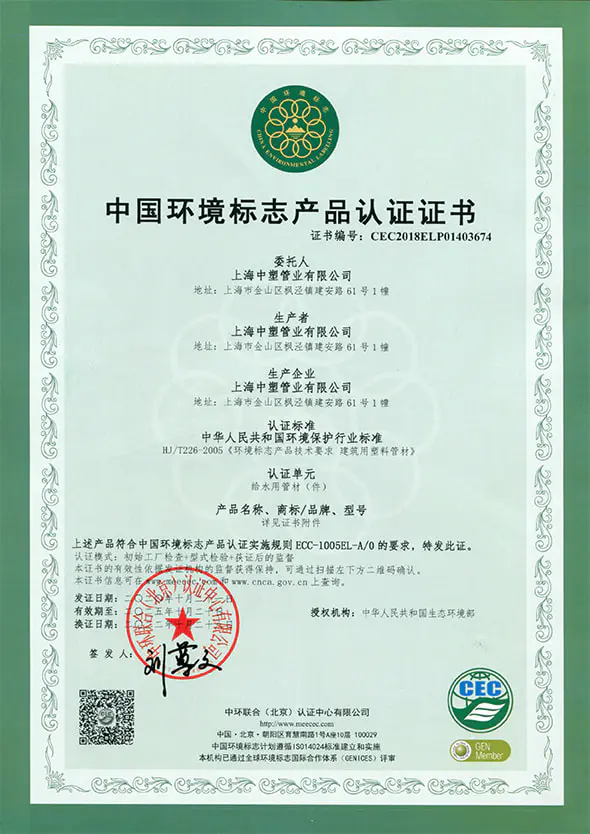

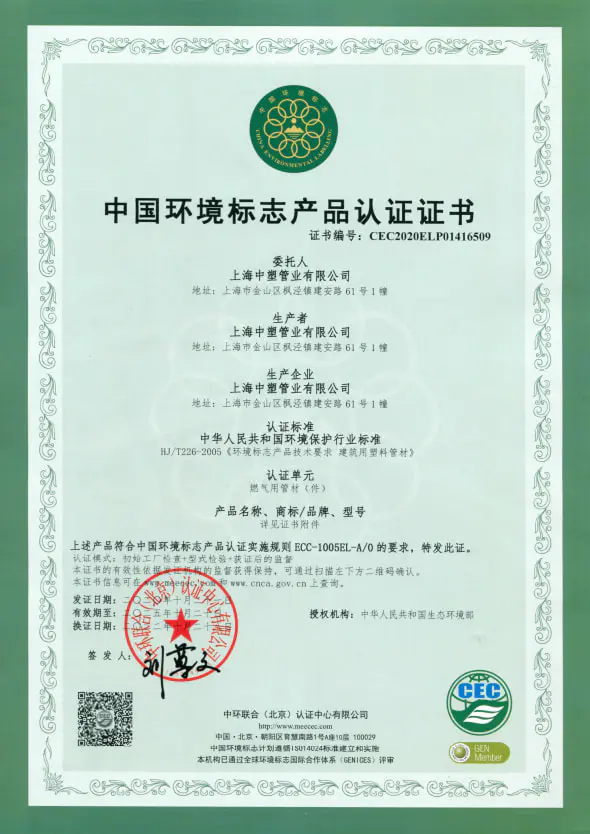

ZHSU uses only 100% virgin raw materials sourced from reputable suppliers such as Borealis and South Korean brands. These premium-grade materials ensure that the PP-RCT pipes are not only environmentally friendly but also resistant to chemical corrosion, making them suitable for a wide range of applications.

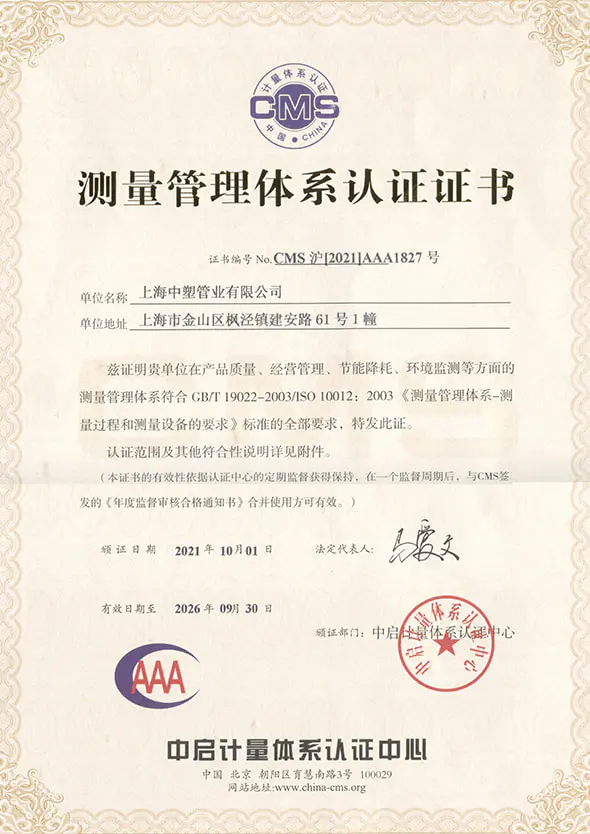

Furthermore, all ZHSU products are manufactured in strict compliance with ISO9001 (Quality Management), ISO14001 (Environmental Management), and OHSAS18001 (Occupational Health and Safety) standards. This comprehensive management system has earned ZHSU recognition as a “Shanghai Famous Brand Product,” “Shanghai High-Tech Enterprise,” and “Shanghai Famous Trademark.”

Applications of PP-RCT Pipes in Real Projects

The unique properties of PP-RCT pipes have led to their widespread adoption in various sectors:

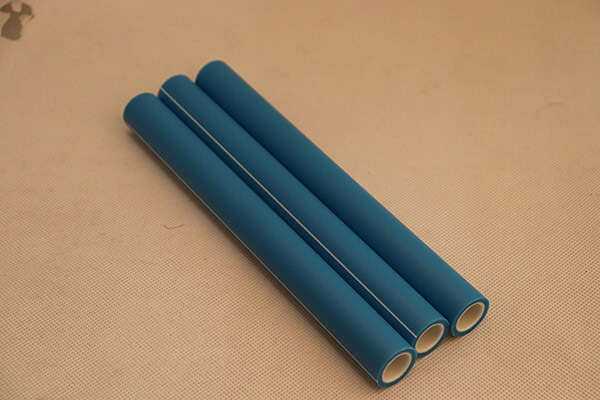

Building Water Supply Systems : In residential and commercial buildings, PP-RCT pipes are used for both cold and hot water distribution. Their ability to withstand high temperatures and pressures without degradation ensures a long service life and minimal maintenance.

Radiant Floor Heating Systems : Due to their flexibility and heat resistance, PP-RCT pipes are commonly used in underfloor heating systems. They provide efficient and uniform heat distribution while maintaining structural integrity under continuous operation.

Industrial Process Piping : Many industries require the transport of hot liquids or steam. PP-RCT pipes offer a lightweight yet robust alternative to metal piping, reducing installation costs and improving energy efficiency.

Municipal Infrastructure : ZHSU’s PP-RCT pipes are increasingly being used in municipal water supply projects, particularly in regions with extreme climate conditions. Their durability and resistance to environmental stress cracking make them ideal for underground installations.

Rural Drinking Water Projects : As part of national initiatives to improve rural water access, ZHSU has developed large-diameter PE pipes up to DN1200mm, complementing its PP-RCT product line. These solutions help deliver clean water safely and efficiently to remote areas.

Commitment to Innovation and Sustainability

ZHSU adheres to a development strategy centered around creating first-class enterprises, producing world-class products, providing exceptional services, and establishing top-tier brands in the HDPE and PP-RCT pipe industries. Guided by core values such as knowledge, courage, truth-seeking, and innovation, the company continues to push the boundaries of plastic pipe technology.

With a strong belief in sustainability and corporate social responsibility, ZHSU cherishes every drop of water and strives to contribute to global water conservation efforts. Its eco-friendly manufacturing processes and commitment to using non-toxic, recyclable materials reflect this vision.

Global Reach and Customer Satisfaction

Today, ZHSU's products are not only popular across China but have also gained traction in international markets such as Southeast Asia, Africa, and Latin America. The company offers competitive pricing, reliable quality, and professional after-sales service, enabling customers to achieve long-term value and mutual growth.

ZHSU remains dedicated to cooperating sincerely with both domestic and international clients, sharing the joy of creation and prosperity through innovative solutions and outstanding performance. Whether it's for urban infrastructure, rural development, or industrial applications, ZHSU’s PP-RCT pipes stand out as a symbol of excellence in modern piping technology.

PP-RCT pipes represent the future of high-performance plastic piping systems. With their superior pressure resistance, long-term thermal stability, and adaptability to demanding environments, they are the preferred choice for high-temperature water transportation. At Shanghai Zhongsu Pipe Co., Ltd., these qualities are backed by advanced technology, strict quality control, and a commitment to innovation—making ZHSU a trusted partner for engineers, contractors, and project developers worldwide.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie