In the world of modern plumbing and piping systems, fittings play a crucial role in connecting, directing, and distributing fluid flow. Among these fittings, the PPR Cross is a specialized yet essential component used to manage complex piping layouts with precision and efficiency. Though not as widely recognized as elbows or tees, the PPR Cross offers unique advantages when it comes to fourway piping intersections.

Understanding the PPR Cross

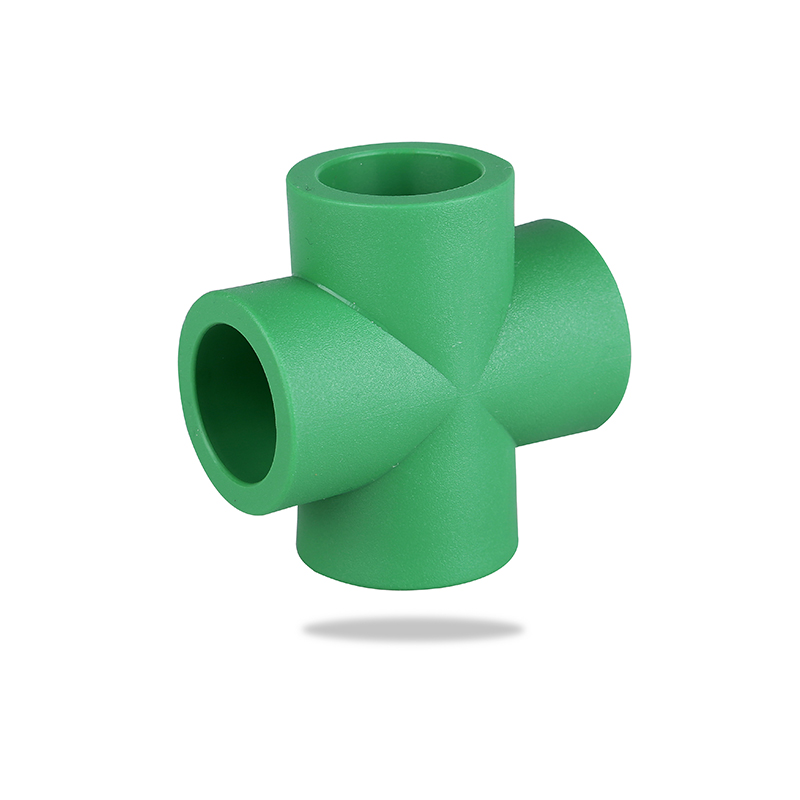

A PPR Cross is a fourway pipe fitting made from Polypropylene Random Copolymer (PPR). It has a symmetrical shape with four equalsized outlets, arranged at 90degree angles in the shape of a cross. This allows it to connect four PPR pipes in a central intersection, enabling fluid to flow in multiple directions simultaneously.

Unlike a tee, which connects three pipes in a Tshaped configuration, or an elbow, which simply redirects flow, the cross fitting is designed for more complex layouts where fluids must be distributed evenly or merged from different sources. The PPR Cross serves as a central point of distribution or collection, often found in heating systems, water supply networks, and industrial pipelines.

The Role of PPR Material

The performance of the PPR Cross is largely defined by the material it is made from. Polypropylene Random Copolymer (PPR) is a highperformance plastic known for its outstanding mechanical and chemical properties. It is widely used in hot and cold water systems due to its reliability, safety, and ease of installation.

PPR is particularly valued for its high temperature resistance, withstanding continuous exposure to water temperatures up to 95°C. It is also nontoxic and corrosionresistant, making it suitable for drinking water systems and other applications where hygiene and longterm durability are essential.

Additionally, PPR has low thermal conductivity, which helps reduce heat loss in hot water pipelines. It is resistant to scaling, chemical corrosion, and pressure stress, allowing PPR fittings like the cross to maintain integrity even under demanding conditions.

Structural Design and Function

The PPR Cross is engineered with both external symmetry and internal precision. Each of its four outlets is designed to match standard PPR pipe diameters, such as 20mm, 25mm, or 32mm. The inner surface of the fitting is smooth to ensure uninterrupted water flow and minimize friction or turbulence.

Internally, the design ensures balanced distribution of pressure and flow. The cross intersection is carefully molded to maintain structural strength where the four arms meet. This central area is typically the most stresssensitive zone, so manufacturers pay special attention to reinforcing it.

The function of the PPR Cross is to split or combine fluid flow at a central node. For instance, in a heating system, it may be used to divide heated water from a single source into four different circuits. In a water supply system, it might collect water from multiple lines and send it toward a common destination. Its design simplifies what would otherwise require multiple tee fittings and additional joints, reducing the chances of leakage and saving space.

Where PPR Cross Fittings Are Used

Although not required in every plumbing system, the PPR Cross becomes indispensable in complex installations. It is most commonly found in the following applications:

Residential and commercial water supply systems: especially where multiple distribution lines originate from a central source.

Underfloor heating systems: where water must be sent to different zones evenly.

Agricultural irrigation: to distribute water to several field lines from a central point.

Industrial fluid transport: in factories or chemical processing plants, where process fluids need to be managed in multiple directions.

In each of these settings, the ability of the PPR Cross to streamline distribution makes it both a practical and economical choice.

Differences from Other Fittings

The PPR Cross differs significantly from other standard pipe fittings in both form and function. While elbows and tees are used more frequently for directional changes and branching, the cross is chosen specifically when a true fourway connection is needed.

Its use can help reduce the total number of joints in a system, which is important because every joint is a potential point of failure. Fewer joints also mean faster installation and lower material costs over time. However, due to its symmetrical design, the PPR Cross requires careful planning to ensure that all four outlets are properly aligned and utilized, or securely sealed if not in use.

Standard Sizes and Compatibility

PPR Cross fittings are manufactured according to international and regional piping standards to ensure uniformity and compatibility. Common sizes range from 20mm to 63mm in diameter, with larger sizes available for industrial applications. They are compatible with other PPR pipes and fittings through heat fusion welding, a process that creates a seamless, leakproof joint by melting the pipe and fitting together under controlled temperature and pressure.

This heat fusion process ensures the longterm reliability of the system, making it resistant to mechanical stress and environmental degradation.

The PPR Cross is a highly functional and purposespecific fitting that supports efficient and reliable piping layouts. Though less commonly used than elbows or tees, it becomes essential in systems that require a balanced and centralized fluid distribution or collection point.

With its robust PPR construction, symmetrical design, and suitability for both residential and industrial applications, the PPR Cross offers longterm performance, minimal maintenance, and safe operation. Understanding its role in modern plumbing systems helps installers, engineers, and planners design networks that are not only functional but also costeffective and futureproof.

Great! Here's Part Two of the article, titled “Applications of PPR Cross in RealWorld Systems,” written in fluent, professional English and approximately 1000 words, continuing the same tone and structure as Part One.

Applications of PPR Cross in RealWorld Systems

In piping and plumbing design, functionality is often determined not only by the quality of materials but also by the efficiency of the system layout. The PPR Cross, with its unique fourway configuration, offers a valuable solution for engineers and installers who need to manage fluid distribution across multiple branches from a single point. Though it is not the most frequently used fitting, it plays a critical role in specific applications where space optimization and directional balance are necessary.

1. Residential Plumbing Systems

One of the most common settings where PPR Cross fittings are used is in residential water supply networks. In many modern homes, especially those built with energy efficiency and smart layout in mind, PPR Cross fittings serve as central junction points from which water can be distributed to multiple areas of the house.

For example, a cross fitting might be installed behind a wall where one line brings in cold water from the main supply, and three additional lines lead to the bathroom, kitchen, and laundry area. Instead of using multiple tee fittings, the installer can use a single PPR Cross to simplify the installation. This approach reduces the number of joints and lowers the potential for future leaks.

In highrise apartment buildings, where vertical water distribution is essential, PPR Crosses can be integrated into floorbyfloor piping layouts to deliver water efficiently to various units without complex branching systems.

2. Underfloor and Central Heating Systems

Another prominent application of PPR Cross fittings is in hydronic heating systems, particularly underfloor heating. In these systems, warm water is circulated through a network of pipes embedded in the floor, providing even, energyefficient heat throughout the building.

The PPR Cross serves as a key junction to distribute the heated water to different loops or zones within the floor plan. For instance, a single PPR Cross can branch warm water into four distinct zones—such as the living room, kitchen, bathroom, and hallway—allowing each zone to receive a consistent flow without the need for multiple tee installations.

This not only saves installation time but also ensures balanced water distribution, which is critical for maintaining even temperature levels across different parts of the floor.

In central heating systems that use radiators, PPR Cross fittings are also used to direct water to multiple radiators on the same floor, or to return water from different radiators back to the boiler in a centralized manner.

3. Agricultural Irrigation Systems

In agriculture, efficient water management is key to crop health and operational cost control. PPR Cross fittings are widely used in irrigation systems where water needs to be distributed evenly to multiple field lines.

A typical example is in drip or sprinkler irrigation setups, where a central pipe supplies water to several lateral lines. A PPR Cross installed at the intersection allows for fourway distribution from a single water source, reducing the need for multiple tees and complex valve combinations.

Because PPR material is resistant to corrosion and chemical fertilizers, the cross fitting holds up well in environments where exposure to soil, pressure changes, or treated water is common. It can be buried underground without the risk of rusting or decay, making it a longlasting solution for farms and greenhouses.

4. Commercial and Public Buildings

In large commercial buildings such as offices, hotels, and shopping malls, space efficiency and system reliability are top priorities. Plumbing and HVAC systems in these buildings often involve long distances and multiple branching routes for water supply, waste management, or climate control.

PPR Cross fittings are used to simplify pipe networks that must serve multiple zones or floors. For instance, in a hotel, a central pipe may carry water vertically through the building, and PPR Crosses are used at each floor to distribute water horizontally to guest rooms on either side of the corridor, as well as auxiliary areas like utility rooms or kitchens.

The use of PPR Crosses in these cases reduces the total number of joints, minimizes installation labor, and ensures a more compact system layout behind walls and ceilings.

5. Industrial and Process Applications

Industries such as food processing, chemical manufacturing, and pharmaceutical production require clean, noncorrosive, and pressureresistant piping systems. PPR Cross fittings are often found in such settings because they offer the ability to direct process fluids in multiple directions while maintaining system integrity and hygiene.

In a chemical mixing plant, for example, different fluids may be introduced into a single line using a cross connection, or mixed fluid might be distributed to different processing units. The nontoxic and chemicalresistant nature of PPR ensures compatibility with a wide range of industrial substances.

Additionally, the seamless heat fusion method used to connect PPR Cross fittings with pipes eliminates the risk of leaks or contamination, which is particularly important in regulated industries.

6. Renewable Energy Systems

As renewable energy systems like solar water heating become more common, PPR Crosses are also finding applications in distributing heated water to various parts of a building. In solar thermal systems, heated water collected from rooftop panels can be directed into multiple circuits using a PPR Cross, allowing for integration with underfloor heating, storage tanks, and domestic water lines.

The PPR material’s ability to withstand high temperatures and its insulating properties make it an ideal match for these systems, which often operate under variable pressure and temperature conditions.

While the PPR Cross may appear to be a simple fitting at first glance, its range of applications proves that it is an essential part of many advanced piping systems. From residential homes to large industrial plants, it provides a compact, efficient, and reliable way to manage fourway fluid flow.

Its usefulness becomes particularly evident in projects that demand precision, durability, and reduced installation complexity. By replacing multiple individual fittings with a single cross fitting, installers and engineers can save both time and materials—while ensuring a cleaner and more organized pipe layout.

Performance Features of PPR Cross

In modern piping systems, reliability and efficiency go hand in hand. It is not enough for a component to simply serve its function—it must also perform consistently over time, under varying pressures, temperatures, and environmental conditions. This is especially true in systems that handle water distribution, heating, or chemical transport. In this context, the PPR Cross stands out not only for its functional design but also for its exceptional performance characteristics.

1. High Temperature Resistance

One of the defining performance attributes of PPR Cross fittings is their ability to withstand elevated temperatures. Made from Polypropylene Random Copolymer (PPR), these fittings can handle continuous water temperatures up to 95°C, with shortterm peaks even higher.

This makes the PPR Cross especially suitable for systems such as:

Domestic hot water supply

Underfloor heating

Radiatorbased heating circuits

Solar thermal energy systems

Unlike many metal fittings, PPR does not corrode or weaken due to constant heat exposure. Its thermal stability ensures that expansion and contraction are minimal, especially when installed using proper design practices like compensators or flexible joints.

2. Excellent Pressure Endurance

In addition to high temperature resistance, the PPR Cross is engineered to endure significant internal pressure. Most highquality PPR fittings are rated for pressure classes like PN16, PN20, or PN25, which represent the maximum pressure (in bar) they can safely handle at 20°C.

Even at elevated temperatures, PPR Cross fittings maintain structural integrity within the approved range. This makes them ideal for use in pressurized systems such as:

Highrise water supply networks

Centralized heating or cooling circuits

Agricultural and industrial pumping systems

The robust wall thickness of the PPR Cross, combined with precision molding and fusionwelded joints, reduces the risk of bursting, cracking, or stress failures over time.

3. Long Lifespan and Material Stability

A major advantage of PPR piping components, including the cross fitting, is their long operational lifespan. When installed correctly, a PPR system can last 50 years or more under normal conditions.

The reason for this durability lies in the molecular structure of PPR, which offers high resistance to:

Creep (longterm deformation under constant stress)

Oxidation from oxygen in water

UV degradation when installed away from direct sunlight

Chemical attacks from mildly acidic or alkaline substances

These features make the PPR Cross an excellent choice for permanent installations where maintenance access may be limited or where longterm performance is critical.

4. Chemical Resistance

Another key performance feature is the PPR Cross's strong resistance to a wide range of chemicals. Unlike metal fittings that may rust, pit, or scale when exposed to aggressive media, PPR remains inert when in contact with:

Chlorinated water

Saline solutions

Weak acids and bases

Organic compounds (including alcohols and glycols)

This characteristic is especially valuable in systems like:

Laboratory or medical fluid transport

Chemical mixing or dosing pipelines

Foodgrade water systems

The nonreactive nature of PPR also ensures that no harmful substances leach into drinking water, preserving safety and quality.

5. LeakFree Connections Through Heat Fusion

One of the most impressive technical benefits of the PPR Cross is the fusion welding process used during installation. Instead of relying on threads, glues, or gaskets, PPR fittings are heat welded to pipes using specialized welding tools.

Here’s how it works:

The pipe and the PPR Cross fitting are both heated to a specified temperature.

Once the surfaces soften, they are quickly joined together.

As the plastic cools, the molecules of both pieces bond into a single, seamless unit.

This results in a leakfree connection that is stronger than the pipe itself. It eliminates potential weak points and dramatically reduces the risk of joint failure over time.

6. Smooth Internal Surface for Optimal Flow

Unlike metal pipes, which may corrode or accumulate scale over time, the inner surface of a PPR Cross is smooth and nonporous. This has two important effects:

Reduces flow resistance, allowing fluids to move with minimal friction and maintaining high efficiency

Prevents the buildup of mineral deposits, bacteria, or other contaminants

This smoothness also contributes to energy efficiency in pumped systems, reducing pressure loss and improving flow uniformity across all outlets.

7. Thermal and Acoustic Insulation Properties

PPR as a material naturally provides insulating properties, which benefit the system in multiple ways:

Thermal insulation: PPR reduces heat loss in hot water systems, helping to maintain temperature and reduce energy consumption.

Acoustic insulation: The density and texture of the material dampen the noise of flowing water, especially in highpressure systems, contributing to a quieter environment in residential and commercial buildings.

In buildings where noise reduction is a priority—such as hospitals, schools, or highend residences—this feature adds considerable value.

8. Safe, NonToxic, and EcoFriendly

Finally, PPR Cross fittings are completely nontoxic, making them safe for potable water applications. Unlike some older plastic systems that contained harmful chemicals (such as PVC with plasticizers), PPR contains no heavy metals or hazardous additives.

Additional environmental benefits include:

Recyclability: PPR materials can be recycled, reducing environmental impact.

Low carbon footprint during production, especially compared to metal alternatives.

No chemical emissions during use, which makes it ideal for green buildings and sustainable infrastructure.

This makes the PPR Cross a smart choice not only for performance, but also for environmental responsibility.

The performance features of the PPR Cross are a reflection of both its intelligent design and its advanced material composition. From high temperature and pressure resistance to chemical stability and seamless welding, every characteristic is tailored to deliver reliable, longterm performance in demanding conditions.

Whether installed in a home, factory, or commercial building, the PPR Cross offers peace of mind through its durability, safety, and efficiency. It’s more than just a connector—it’s a highperformance solution for modern fluid distribution systems.

Excellent! Below is Part Four: How to Select the Right PPR Cross, written in fluent English and approximately 1000 words, continuing the same tone and structure as the previous parts.

How to Select the Right PPR Cross

Choosing the right components for a piping system is crucial for its longterm performance, safety, and efficiency. While the PPR Cross may seem like a simple fitting at first glance, selecting the wrong size, pressure rating, or material grade can lead to costly problems during installation or operation. Whether you're working on a residential water line, a heating circuit, or an industrial system, making the right choice requires careful attention to several key factors.

This section outlines the most important considerations when selecting a PPR Cross for your project, including sizing, pressure rating, certification, environmental compatibility, and installation requirements.

1. Determine the Correct Pipe Size

The first and most basic requirement when selecting a PPR Cross is to match the correct pipe size. PPR pipes and fittings are available in a range of nominal diameters, typically measured in millimeters.

Common sizes include:

20mm (used for domestic water supply lines)

25mm and 32mm (used in mediumcapacity residential or small commercial systems)

40mm to 63mm (used for higher flow rates or central distribution systems)

To choose the right size:

Check the diameter of the connected pipes. All four outlets of the cross must match the pipe diameter unless you're using reducers or adaptors.

Account for future expansion. In some cases, it may be wise to use a slightly larger size if the system is expected to carry more load in the future.

Ensure internal consistency across the entire system. Mixing incompatible sizes or using poorly matched reducers can result in poor flow balance and pressure loss.

2. Understand the Pressure Rating (PN Rating)

Each PPR fitting is assigned a PN (Pressure Nominal) rating, which indicates the maximum pressure the fitting can handle at a reference temperature of 20°C. The most common ratings for PPR Cross fittings include:

PN16 – suitable for cold water or lowpressure systems

PN20 – commonly used for hot and cold water supply in homes and buildings

PN25 – suitable for highpressure or hightemperature applications

Keep in mind that pressure capacity decreases as temperature increases. For example, a PN20 fitting may perform well at 20°C but could lose up to 50% of its pressure capacity at 80–90°C.

To ensure safety and durability:

Match the PN rating to the intended application

Never operate a system near or beyond the maximum rated pressure

Refer to the manufacturer's pressuretemperature performance chart when working with hot water or steam systems

3. Confirm Product Certification and Standards Compliance

For critical systems—especially those carrying drinking water or being used in commercial or public buildings—certified and standardized fittings are a must. Highquality PPR Cross fittings should comply with recognized international or regional standards such as:

ISO 15874 (International standard for PPR piping systems)

DIN 8077/8078 (German standards for dimensions and performance)

GB/T 18742 (Chinese standard for polypropylene piping systems)

Additionally, look for certifications such as:

WRAS (Water Regulations Advisory Scheme – UK)

NSF (National Sanitation Foundation – USA)

CE marking (Europe)

ISO 9001 (Quality management certification)

Using certified components ensures that the material quality, dimensions, and performance ratings have been independently tested, which is particularly important in regulated environments.

4. Check for Material Purity and Grade

Not all PPR fittings are created equal. While most PPR Cross fittings are made from Polypropylene Random Copolymer Type 3, there are variations in purity, color additives, and processing methods.

Here’s what to look for:

Virgin PPR material – Always choose fittings made from pure, nonrecycled material for water supply or heating systems. Recycled materials may contain impurities that degrade over time.

Color coding – Some manufacturers use color to indicate material grade or application (e.g., green for domestic water, blue for cold water, grey for industrial).

UV protection additives – For outdoor installations, choose fittings with UVstabilized materials to avoid degradation from sunlight exposure.

Always request a technical datasheet or material certification from the supplier if the system is highvalue, longterm, or safetycritical.

5. Evaluate Thermal and Environmental Conditions

The installation environment has a significant impact on fitting selection. Consider the following when choosing a PPR Cross:

Operating temperature – For hightemperature systems (e.g., heating or solar water), select a PN25 fitting and confirm the pressuretemperature resistance from the manufacturer.

Exposure to chemicals – In case of exposure to detergents, fertilizers, or chemicals, confirm the material’s chemical compatibility.

Outdoor or underground use – For outdoor applications, ensure UV protection. For underground installations, make sure the fittings are resistant to soil pressure and moisture.

Failure to match the product’s characteristics with the environmental conditions can lead to premature failure, cracks, or leaks.

6. Consider Installation Tools and Compatibility

Heat fusion welding is the standard installation method for PPR Cross fittings. Before selecting a specific brand or model:

Confirm compatibility with your welding tools – Some manufacturers produce fittings with slightly different socket depths or melting characteristics.

Check for preformed guides on the fitting to ensure alignment during welding.

Assess ease of access – In tight or recessed areas, a large fourway fitting may require extra clearance during installation.

Where space is limited, it may be helpful to preassemble segments before positioning them in the final installation location.

7. Source from Reputable Brands and Suppliers

While price is an important factor, selecting a reputable brand often pays off in longterm reliability and support. Trusted manufacturers invest in quality control, certification, and R\&D to ensure their products perform as promised.

When sourcing PPR Cross fittings:

Avoid unbranded or lowquality imports without documentation.

Request samples or testing data if purchasing in bulk.

Choose suppliers who offer technical support, warranty, or installation guidance.

Spending slightly more on a trusted brand can help prevent system failures, water damage, or expensive repairs in the future.

Selecting the right PPR Cross is about much more than simply matching size and shape. It involves understanding pressure and temperature requirements, verifying material quality and certification, and planning for environmental and installation conditions.

By carefully evaluating these factors, you can ensure that your piping system performs efficiently, safely, and reliably for decades. The PPR Cross, when correctly selected and installed, becomes a critical building block in highperformance piping networks—offering both structural integrity and design simplicity.

Great! Here's Part Five: Installation Methods and Best Practices for PPR Cross, written in professional, fluent English and approximately 1000 words, continuing the structure and tone of the previous parts.

Installation Methods and Best Practices for PPR Cross

Installing a PPR Cross fitting properly is crucial for ensuring a longlasting, leakfree, and efficient piping system. While the PPR Cross offers excellent durability and performance, the true value of this fitting can only be realized when it is installed according to best practices. This includes proper preparation, correct heat fusion techniques, alignment, and postinstallation testing.

In this section, we’ll walk through the standard installation procedure, highlight common mistakes to avoid, and share practical tips to ensure a professional and reliable installation.

1. Understanding the Installation Method: Heat Fusion

The most common and recommended method for connecting a PPR Cross to pipes is thermal fusion welding. This method involves heating the ends of both the fitting and the pipes using a fusion welding tool, then joining them together to form a permanent molecular bond.

Unlike threaded or glued joints, heat fusion creates a homogeneous connection that is just as strong—or even stronger—than the surrounding material. When performed correctly, it results in a seamless, leakproof joint with no risk of loosening over time.

2. Tools Required for Installation

Before starting the installation, ensure you have the following tools and materials:

PPR pipe cutter – for making clean, straight pipe cuts

Pipe calibration tool – to round the pipe ends (especially important after cutting)

Deburring tool or scraper – to smooth rough edges

Fusion welding machine – with temperaturecontrolled heating sockets

Marking pen or chalk – for depth indication

Measuring tape or ruler

Gloves and protective gear – to handle heated components safely

It’s also a good idea to have a thermometer or thermostatic control to monitor the welding temperature, which typically ranges between 250°C and 270°C.

3. StepbyStep Installation Procedure

Here’s a standard procedure for installing a PPR Cross with four connected pipes:

Step 1: Prepare the Pipe Ends

Cut the pipes to the desired lengths using a pipe cutter.

Ensure that the ends are square and clean.

Use a calibration tool and deburring tool to remove any burrs and to restore the roundness of the pipe after cutting.

Step 2: Mark Insertion Depth

Measure and mark the insertion depth on each pipe. This depth depends on the pipe diameter and ensures that the pipe is inserted fully into the socket of the PPR Cross during welding.

Step 3: Heat the Pipe and Fitting

Once the welding tool has reached the correct temperature, insert the pipe end into the heating sleeve and the fitting end (PPR Cross) onto the opposite heating spigot.

Hold them in place for the prescribed heating time (typically 4–8 seconds for small diameters; longer for larger sizes). Do not rotate while heating.

Step 4: Join the Pipe and Fitting

Quickly remove both the pipe and the PPR Cross from the welding sockets and push them together straight and firmly until the pipe reaches the marked insertion depth.

Do not twist or rotate during joining.

Hold them in place for a few seconds to allow initial cooling and bonding.

Step 5: Allow Full Cooling

Let the joint cool naturally (usually 30 seconds or more).

Do not stress, bend, or move the joint while it is cooling.

Repeat the process for the remaining outlets of the cross.

4. Best Practices for Accurate and Durable Installation

To achieve optimal results, follow these proven best practices:

Maintain cleanliness: Always clean pipe ends and fitting sockets before welding. Dirt or grease can compromise the bond.

Use consistent heating time and temperature: Uneven heating can lead to weak joints or partial fusion.

Avoid overinsertion: Pushing the pipe too far beyond the marked depth can deform the fitting.

Work in a clean, temperaturecontrolled environment: Avoid performing heat fusion in very cold or windy conditions, which can affect the weld.

Align pipes carefully: Ensure that all four pipes are aligned before starting. Once a pipe is welded in place, adjusting its direction is not possible.

Preplan your layout: Due to the fixed angles of the cross, plan how pipes will approach each outlet to avoid conflicts or space issues.

5. Common Installation Mistakes to Avoid

Even experienced installers can make mistakes. Here are some common errors to watch out for:

Underheating or overheating the joint: This leads to weak bonding or deformation.

Using damaged or contaminated tools: Scratched or dirty heating elements can affect weld quality.

Forcing the pipe at an angle: This causes stress on the joint and may lead to cracks over time.

Skipping calibration: An improperly shaped pipe end can result in poor fit and uneven melting.

Not checking alignment: If any of the four pipe directions are misaligned, the system may suffer from uneven pressure and leakage risk.

Rushing the cooling phase: Moving the pipe before the weld is set weakens the bond.

Proper training and patience are key to avoiding these issues.

6. PostInstallation Testing

Once the entire section containing the PPR Cross has been installed:

Perform a pressure test (commonly using water or air) to check for leaks.

Ensure that the test pressure is applied gradually and held for at least 30 minutes.

Observe all joints carefully, especially at the PPR Cross, for signs of seepage or deformation.

If any leaks are found, the affected section must be cut out and reinstalled, as heatfused joints cannot be reopened or rewelded.

7. Additional Tips for Complex Installations

If not all four outlets of the cross are needed, cap the unused ends with PPR end caps, properly welded to ensure a sealed system.

For large systems, label each pipe direction during installation for easier identification and maintenance later.

In vertical installations, support the piping above and below the cross to prevent stress from the weight of long pipe runs.

Leave enough space around the PPR Cross to accommodate the welding tool and the installer’s hands—especially important in tight ceiling or wall cavities.

The PPR Cross is a highly dependable fitting when installed correctly. Its long lifespan, leakfree performance, and mechanical strength depend on proper installation techniques. By following the steps and best practices outlined in this section, you can ensure a clean, strong, and professionalquality joint that will serve reliably for decades.

Whether you're installing it in a home, commercial facility, or industrial setting, a properly welded PPR Cross becomes a seamless part of a robust piping system.

Summary: Understanding and Using the PPR Cross

The PPR Cross is a four-way pipe fitting made from Polypropylene Random Copolymer, designed to distribute or collect fluid in piping systems across four directions. Though not as commonly used as elbows or tees, it plays a vital role in complex layouts where centralized flow management is required.

Thanks to its high resistance to temperature and pressure, the PPR Cross is widely used in residential plumbing, underfloor heating systems, agricultural irrigation, commercial water networks, and industrial fluid transport. Its smooth internal surface, non-toxic material, and ability to withstand chemical exposure make it suitable for both hot and cold water systems.

One of its greatest advantages is its heat fusion installation method, which creates a seamless, leak-proof connection that outlasts mechanical joints. However, proper installation requires precise cutting, calibration, and alignment, along with careful attention to heating time and cooling.

When selecting a PPR Cross, factors such as pipe size, pressure rating (PN class), certification, material purity, and environmental conditions must be considered. Certified products that comply with international standards offer better performance and safety.

Overall, the PPR Cross is a durable, efficient, and eco-friendly solution for modern piping systems. When installed correctly, it enhances the system’s integrity, reduces maintenance, and ensures long-term reliability.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie