Long-term durability and construction economics of High Density Polyethylene (HDPE) Pipes in municipal water supply systems

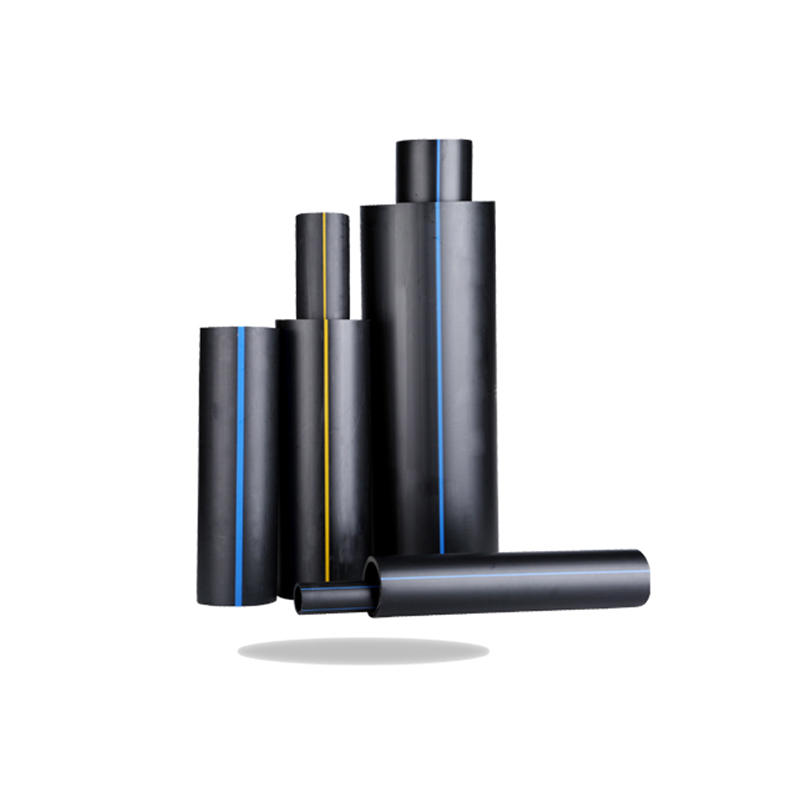

In the ever-evolving landscape of municipal water supply systems, infrastructure reliability, cost-efficiency, and environmental sustainability have become critical concerns. As cities grow and the demand for clean water increases, the materials used in pipeline construction must meet rigorous performance standards. Among the various pipe materials available today, High-Density Polyethylene (HDPE) pipes have emerged as a leading choice due to their exceptional durability, flexibility, and long-term economic benefits.

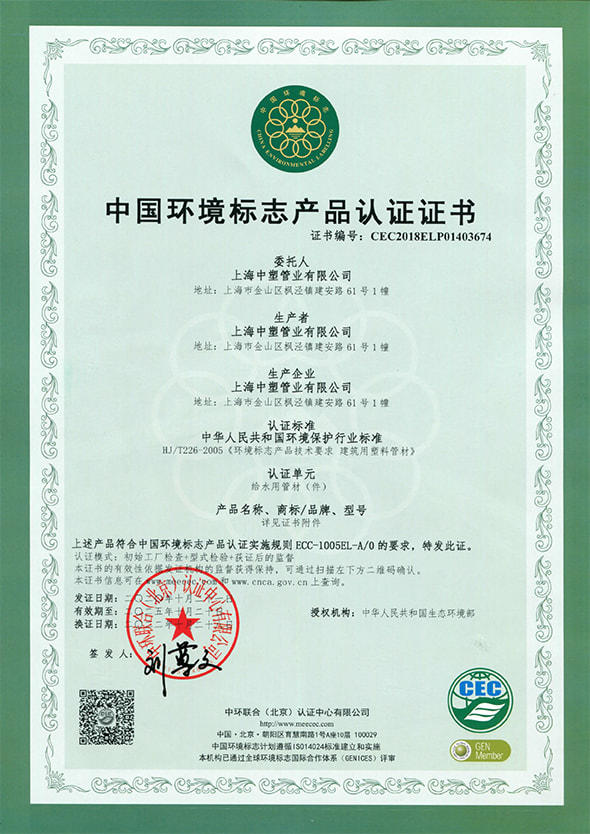

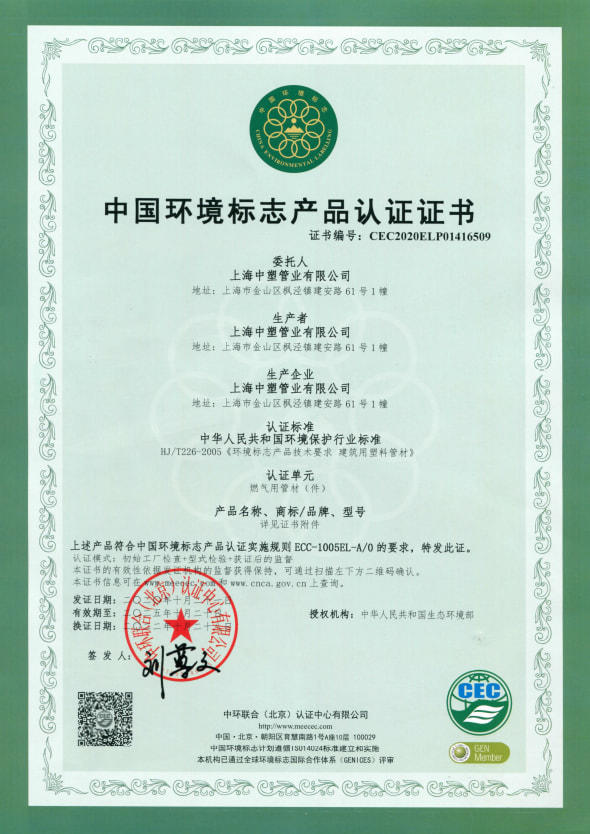

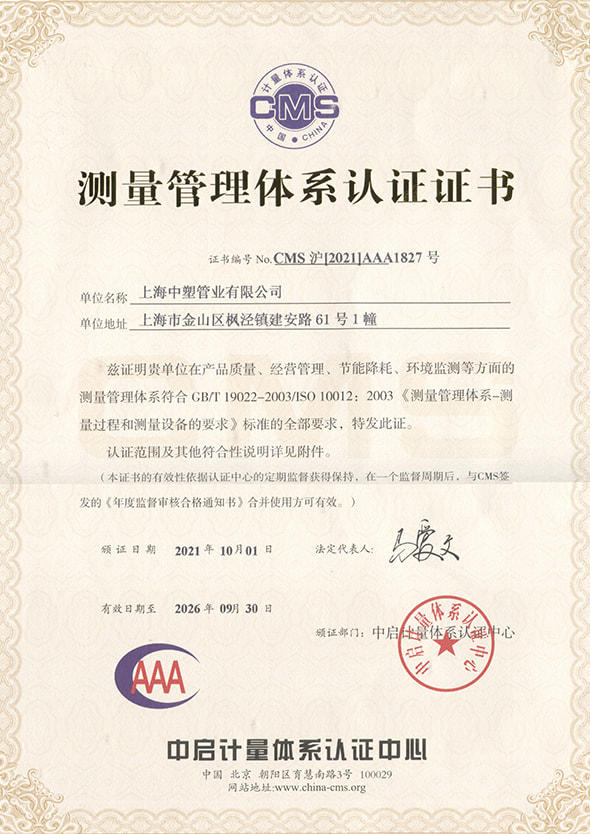

One company that has consistently contributed to this evolution is Shanghai Zhongsu Pipe Co., Ltd. , a trusted name in the production of high-quality plastic piping solutions since its establishment in 2004. With a registered capital of RMB 1.01 billion and a sprawling facility covering 70,000 square meters in Shanghai’s Jinshan District, Zhongsu Pipe has built a solid reputation for innovation, quality, and environmental responsibility in the manufacture of HDPE and PPR piping systems.

The Rise of HDPE Pipes in Municipal Infrastructure

High-Density Polyethylene (HDPE) pipes are thermoplastic polymers known for their excellent chemical resistance, low permeability, and remarkable strength-to-density ratio. These properties make HDPE an ideal material for use in municipal water supply systems where long-term performance and minimal maintenance are essential.

Unlike traditional materials such as concrete or metal, High Density Polyethylene (HDPE) Pipes do not corrode, scale, or degrade when exposed to aggressive soil conditions or chemicals commonly found in water distribution systems. This inherent resistance to corrosion significantly extends the service life of HDPE pipelines—often exceeding 50 years—with minimal need for repairs or replacements.

Moreover, HDPE pipes exhibit excellent flexibility, which allows them to absorb ground movements caused by seismic activity, frost heave, or settlement without cracking or leaking. This characteristic is particularly valuable in urban environments where subsurface conditions can be unpredictable.

Long-Term Durability: Why HDPE Stands Out

Durability is a cornerstone of any municipal water system. High Density Polyethylene (HDPE) Pipes offer several advantages in this regard:

Corrosion Resistance : One of the most significant causes of pipeline failure in traditional systems is corrosion. HDPE pipes are immune to electrochemical and chemical corrosion, ensuring consistent performance over decades.

Leak-Free Joints : HDPE pipes are typically joined using heat fusion techniques, creating a monolithic pipeline with joints that are as strong or stronger than the pipe itself. This eliminates common leakage points found in mechanical joint systems.

UV and Chemical Resistance : HDPE materials, especially those enhanced with UV stabilizers, maintain their structural integrity even under prolonged exposure to sunlight. Additionally, they resist degradation from a wide range of chemicals, making them suitable for both potable and wastewater applications.

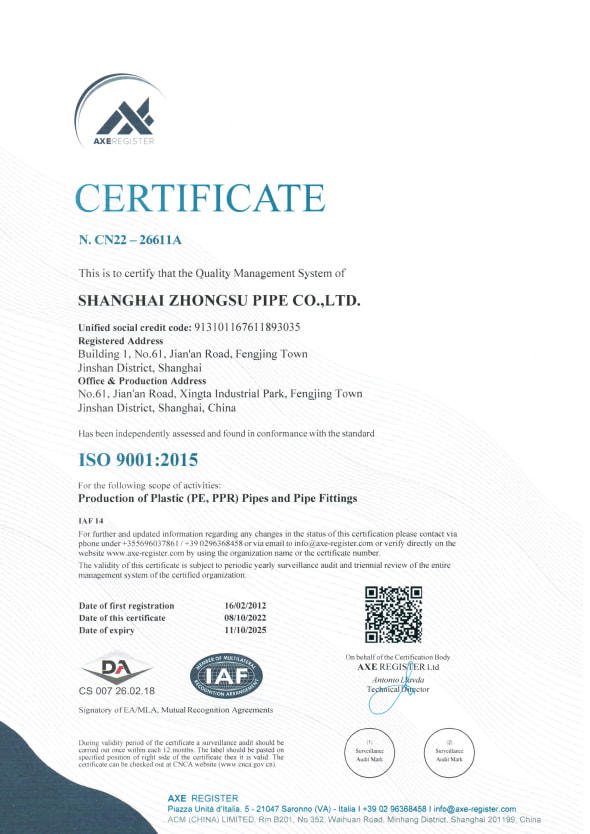

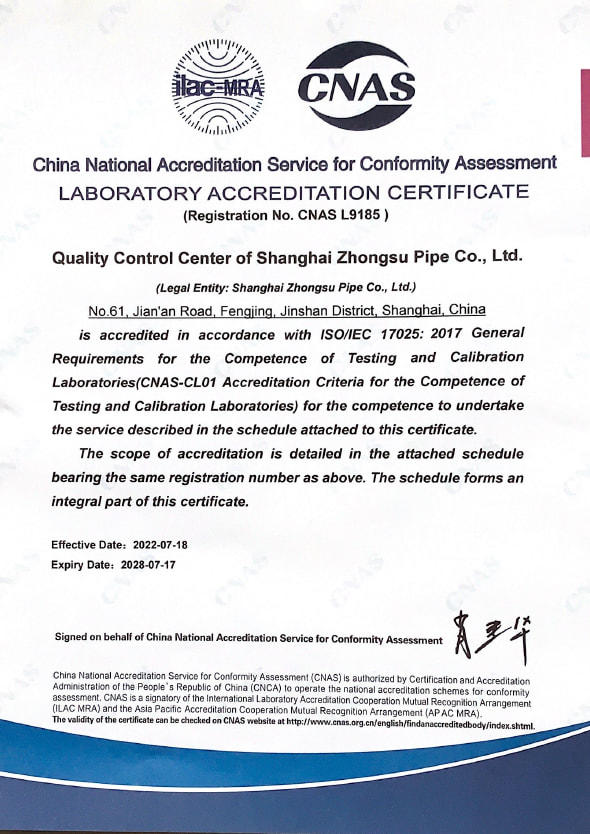

At Shanghai Zhongsu Pipe Co., Ltd. , these principles of durability are embedded into every product. The company produces HDPE pipes and fittings that adhere strictly to international standards and undergo rigorous testing in its CNAS-certified national laboratory. Using 100% virgin raw materials sourced from reputable suppliers like Borealis and South Korean brands, Zhongsu ensures that every HDPE pipe leaving its factory meets the highest benchmarks for safety, performance, and environmental friendliness.

Economic Advantages of HDPE Pipes in Municipal Projects

While durability is crucial, the economic viability of a piping system is equally important for municipal planners and engineers. HDPE pipes offer compelling cost advantages across the entire lifecycle of a project—from installation to maintenance to eventual replacement.

1. Lower Installation Costs

The lightweight nature of HDPE pipes reduces transportation and handling costs. Compared to heavier materials like ductile iron or concrete, HDPE pipes require less heavy machinery and fewer labor hours for installation. Their flexibility also allows for directional drilling and trenchless installation methods, further reducing disruption and cost in urban areas.

Zhongsu Pipe’s advanced manufacturing capabilities enable the production of large-diameter HDPE pipes up to DN1200mm, meeting the demands of large-scale municipal and industrial projects. This capacity positions Zhongsu among the few manufacturers in China capable of producing such high-specification HDPE products.

2. Reduced Maintenance and Repair Expenses

Due to their corrosion resistance and leak-proof joints, High Density Polyethylene (HDPE) Pipes require minimal maintenance throughout their lifespan. In contrast, traditional metallic or concrete pipes often necessitate frequent inspections, repairs, and eventually full replacements, all of which incur significant financial and operational burdens.

For municipalities, this translates into long-term savings on both direct repair costs and indirect losses from water leakage, service interruptions, and public inconvenience.

3. Extended Service Life

With an expected service life of over 50 years, HDPE pipes reduce the frequency of system-wide replacements. This longevity is supported by standardized testing protocols such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and OHSAS 18001 (Occupational Health and Safety), all of which Zhongsu Pipe has successfully implemented.

The company's commitment to quality is further evidenced by its recognition as a “Shanghai Famous Brand Product,” “Shanghai High-Tech Enterprise,” and “Shanghai Famous Trademark.” These accolades underscore Zhongsu’s leadership in delivering economically sound and technically superior HDPE piping systems.

Environmental and Social Responsibility

As global awareness of sustainability grows, so too does the importance of environmentally responsible infrastructure choices. HDPE pipes are fully recyclable and do not leach harmful substances into the environment, making them a green alternative to conventional materials.

At Zhongsu Pipe , environmental stewardship is part of the corporate mission. The company cherishes every drop of water and integrates eco-friendly practices throughout its operations—from sourcing sustainable raw materials to optimizing energy consumption during production. Its dedication to social responsibility aligns with global efforts to promote cleaner, more resilient water supply systems.

Real-World Applications and Global Reach

Zhongsu Pipe’s HDPE products have been widely applied in diverse sectors including building water supply and drainage, municipal infrastructure, rural water network transformation, and even nuclear power plant support systems. The company’s ability to produce large-diameter HDPE pipes has made it a key player in major infrastructure development projects across China and beyond.

Internationally, Zhongsu Pipe’s products are exported to Southeast Asia, Africa, Latin America, and other regions where reliable and affordable water supply systems are in high demand. These markets benefit not only from the technical superiority of HDPE pipes but also from Zhongsu’s commitment to customer-centric service, competitive pricing, and timely delivery.

Future Outlook and Innovation

Looking ahead, the role of HDPE pipes in municipal water supply systems will only expand. Innovations in material science, digital monitoring, and smart infrastructure integration will further enhance the performance and efficiency of HDPE pipelines.

Zhongsu Pipe remains at the forefront of this evolution, guided by its core values of “knowledge, courage, truth-seeking, and innovation.” The company continues to invest in research and development, adopting cutting-edge technologies and expanding its product portfolio to include next-generation piping solutions.

Its strategic vision—to build first-class enterprises, produce world-class products, deliver exceptional service, and establish globally recognized brands—ensures that Zhongsu Pipe will continue to play a pivotal role in shaping the future of municipal water infrastructure.

High-Density Polyethylene (HDPE) pipes represent a paradigm shift in the design and implementation of municipal water supply systems. Their unmatched durability, cost-effectiveness, and environmental benefits make them the preferred choice for modern infrastructure projects.

Shanghai Zhongsu Pipe Co., Ltd. exemplifies how a forward-thinking manufacturer can drive progress in this sector. By combining technological excellence with a strong sense of social responsibility, Zhongsu not only delivers high-performance HDPE piping systems but also contributes meaningfully to the sustainability and resilience of communities around the world.

As urbanization accelerates and water scarcity becomes an increasingly pressing issue, companies like Zhongsu Pipe will be instrumental in ensuring that clean, safe, and reliable water reaches every corner of society—efficiently, affordably, and sustainably.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português