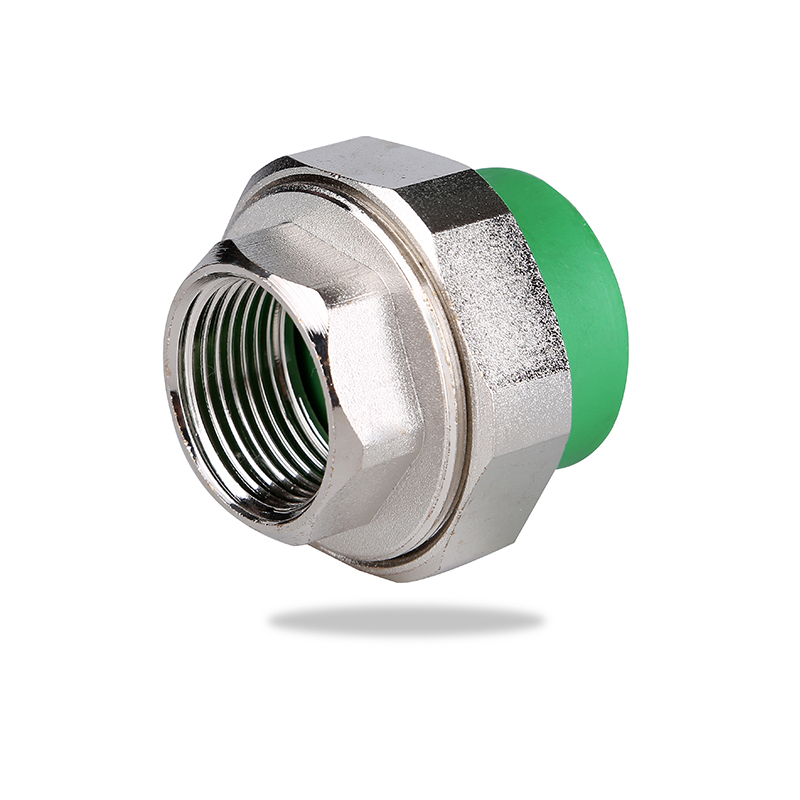

PPR Union (Polypropylene Random Copolymer Union) is a widely used pipe fitting in plumbing and heating systems. Made of PPR (Polypropylene Random Copolymer) material, it is known for its durability, resistance to high temperatures and pressures, and excellent chemical resistance. PPR Union fittings are typically used to connect two pipes or components in a system, allowing for easy disassembly or assembly when needed. These fittings are commonly found in water supply, heating, and industrial applications due to their cost-effectiveness and reliability.

1. Water Supply Systems

One of the most common uses of PPR unions is in residential and commercial water supply systems. They are used to connect various sections of piping in both cold and hot water installations. The ability of PPR pipes and unions to resist corrosion and scale buildup makes them ideal for transporting potable water. Since PPR is a non-toxic material, it does not affect water quality, which is crucial for drinking water systems.

In these systems, PPR unions are used to connect pipes where periodic maintenance or future repairs might be required. The unions allow for quick disassembly and reassembly, making it easier to replace sections of piping without disrupting the entire system.

2. Heating Systems

PPR unions are extensively used in heating systems, especially in underfloor heating and radiator installations. Due to their high thermal resistance, PPR pipes and unions can easily handle hot water temperatures ranging from 70°C to 95°C, making them ideal for both central heating and cooling systems.

In underfloor heating, for example, PPR unions are used to connect pipes in the floor heating system, which is typically used in homes, offices, and commercial buildings. The unions allow for easy maintenance and repairs without the need to disrupt the entire system.

For radiator heating, PPR unions help to connect the radiator to the main heating pipework, providing a secure and reliable connection that can handle both pressure and temperature fluctuations commonly found in heating systems.

3. Industrial Applications

In industrial applications, PPR unions are used for fluid and gas transport systems where the material needs to be resistant to both high pressure and temperature. PPR's resistance to chemicals and its non-corrosive nature make it an excellent choice for industries such as chemical, food processing, pharmaceuticals, and petrochemicals.

For example, in the chemical industry, PPR unions are used to connect pipelines that carry various chemical solutions, where traditional metal pipes might corrode or degrade over time. PPR's superior resistance to chemical corrosion ensures a longer-lasting, safe, and efficient piping system.

In the food processing industry, PPR pipes and unions are often used for transporting non-food fluids such as cleaning solutions or other substances that require non-corrosive, safe materials for transport.

4. Irrigation Systems

PPR unions are widely used in irrigation systems due to their flexibility, durability, and resistance to environmental factors like UV rays and weathering. In both agricultural irrigation systems and landscaping applications, PPR unions are used to connect pipes and components, ensuring a leak-proof and durable connection that can withstand the pressure of water flow in irrigation lines.

The ability to easily disassemble and reassemble sections of an irrigation system is particularly beneficial for seasonal adjustments or repairs. Moreover, the smooth inner surface of PPR pipes reduces friction, helping to maintain efficient water flow without the risk of clogging or scaling.

5. Compressed Air Systems

Another important application for PPR unions is in compressed air systems. PPR’s ability to resist high pressure and temperature fluctuations makes it a reliable option for connecting pipes that transport compressed air in industries like manufacturing, automotive, and construction. PPR unions are used in these systems because of their ability to handle pressure spikes without losing integrity.

Using PPR unions in compressed air systems reduces the need for regular maintenance or repairs compared to traditional materials, like metal or PVC, which may corrode, wear out, or break under extreme conditions.

6. Marine and Outdoor Applications

PPR pipes and unions are also used in marine and outdoor applications, where materials are subject to harsh environmental conditions. The material’s resistance to saltwater corrosion and UV degradation makes it a perfect choice for marine plumbing systems. Whether it's used for fresh water transport in boats or other vessels, or in offshore platforms, PPR’s durability and strength are valuable attributes in these extreme conditions.

For outdoor irrigation systems, especially in areas with high UV exposure, PPR unions are ideal as they do not degrade under sunlight, unlike other materials that may become brittle and break down after prolonged exposure to the sun.

7. HVAC Systems

In HVAC systems (heating, ventilation, and air conditioning), PPR unions are often used to connect piping for chilled water systems or hot water systems. Since PPR can handle a wide range of temperatures and resist corrosion from chemicals found in refrigerants or cooling fluids, it is well-suited for use in these types of systems.

The flexibility of PPR unions makes it easy to install and repair parts of an HVAC system without disturbing the overall operation. This is particularly beneficial in commercial buildings, where HVAC systems are complex and may require frequent maintenance or upgrades.

8. Gas Supply Systems

PPR unions are also used in gas supply systems, where the material’s resistance to corrosion and heat is highly beneficial. While PPR itself is not typically used for transporting natural gas, it is commonly employed in systems for transporting compressed gases like propane or butane. PPR pipes are resistant to rust, which can compromise the quality and safety of the transported gas.

The use of PPR unions allows for quick connections between sections of piping in gas systems, ensuring both ease of installation and reliable performance under pressure.

Benefits of Using PPR Unions

| Benefits | Description |

| Corrosion Resistance | PPR unions are highly resistant to corrosion, unlike metal pipes which may rust or degrade over time. |

| Temperature Resistance | Can withstand high temperatures, making them ideal for hot water and heating systems. |

| Easy Installation | PPR unions can be quickly installed and removed, simplifying maintenance and repairs. |

| Chemical Resistance | PPR is resistant to most chemicals, making it suitable for industrial and agricultural applications. |

| Durability | With a long lifespan, PPR unions are durable and can handle high pressure and stress without deteriorating. |

| Cost-Effective | PPR unions are more affordable compared to alternatives like copper or stainless steel, offering great value. |

| Environmentally Friendly | PPR is a recyclable material, contributing to sustainability and eco-friendliness. |

PPR unions are a versatile and essential component in modern piping systems. From water supply and heating systems to industrial applications, their ability to resist corrosion, handle high temperatures, and provide easy installation and maintenance make them a popular choice across multiple industries. Whether used in irrigation, compressed air systems, or marine applications, the advantages of PPR unions—such as their durability, resistance to chemicals, and cost-effectiveness—make them indispensable for both residential and commercial plumbing needs.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie