During home decoration, the installation quality of the water pipe system directly affects the future safety and living comfort. PPR Coupling is a key connecting component in the PPR pipe system and is widely used in hot and cold water delivery systems. How to correctly use PPR Coupling for installation to ensure that the connection is firm and leak-proof is a skill that every construction worker or DIY enthusiast must master.

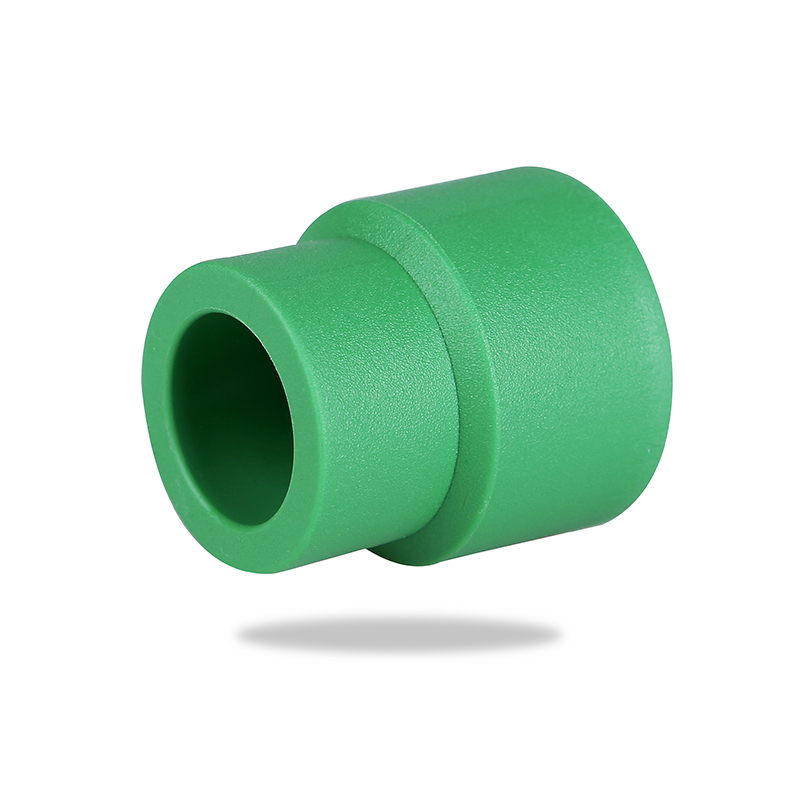

To understand the basic structure and principle of PPR Coupling. PPR Coupling is a straight-through pipe fitting with a smooth inner wall and PPR pipes that can be inserted at both ends. It is usually combined with the pipe by hot melt connection. Its material is random copolymer polypropylene (PPR), which has good high temperature resistance, corrosion resistance and sealing performance. The premise of using Coupling correctly is to have a full understanding of the material itself and choose products that meet national standards.

In actual operation, the correct installation steps are crucial. The first step is to prepare tools and materials, including a dedicated PPR hot melt welding machine, a cutter, a ruler, and qualified PPR pipes and Coupling. The second step is to cut the pipe. The cut must be flat and perpendicular to the pipe body to avoid poor sealing due to tilting. The third step is to mark the insertion depth and heat the pipe and the coupling interface. Pay attention to controlling the hot melt time and temperature (usually about 20 seconds, the temperature is about 260℃). The fourth step is to quickly insert the pipe into the coupling, keep it in a straight line and fix it for a few seconds to complete the cooling and shaping. The whole process needs to be fast and accurate to avoid overheating and deformation of the material or loose connection.

The following details should also be paid attention to during the installation process. First, avoid repeated heating of the same interface, otherwise it will destroy the molecular structure of the material and affect the sealing effect; second, do not forcefully insert or rotate the pipe to avoid forming a virtual connection or leaking point; third, a pressure test should be performed after the installation is completed. It is usually recommended to pressurize the system to 0.8MPa and keep it for more than 30 minutes after the system is installed to observe whether there is leakage to ensure the stability of the overall system.

At the same time, the construction environment will also affect the installation effect. The hot melt connection of PPR Coupling has certain requirements for the ambient temperature. Generally, it should be operated above 5℃ to avoid low temperature causing the material to cool too quickly and the bonding to be loose. The construction site should be kept dry and well ventilated to prevent moisture from affecting the welding quality.

Selecting high-quality PPR Coupling products is also the key to ensuring the quality of installation. Poor-quality pipe fittings may have problems such as uneven wall thickness and raw material doping, which not only affects the connection strength but also shortens the service life. Therefore, when purchasing, you should look for regular brands, check whether the product has relevant certification standards (such as GB/T 18742 national standard), and try to obtain samples for trial installation and testing.

To correctly use PPR Coupling in household water pipe installation, you must not only master scientific installation processes and techniques, but also pay attention to material quality, construction environment and post-testing. Only by being rigorous and meticulous in every link can we ensure that the pipes are firmly connected and well sealed, and truly realize a safe and reliable water supply system.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie