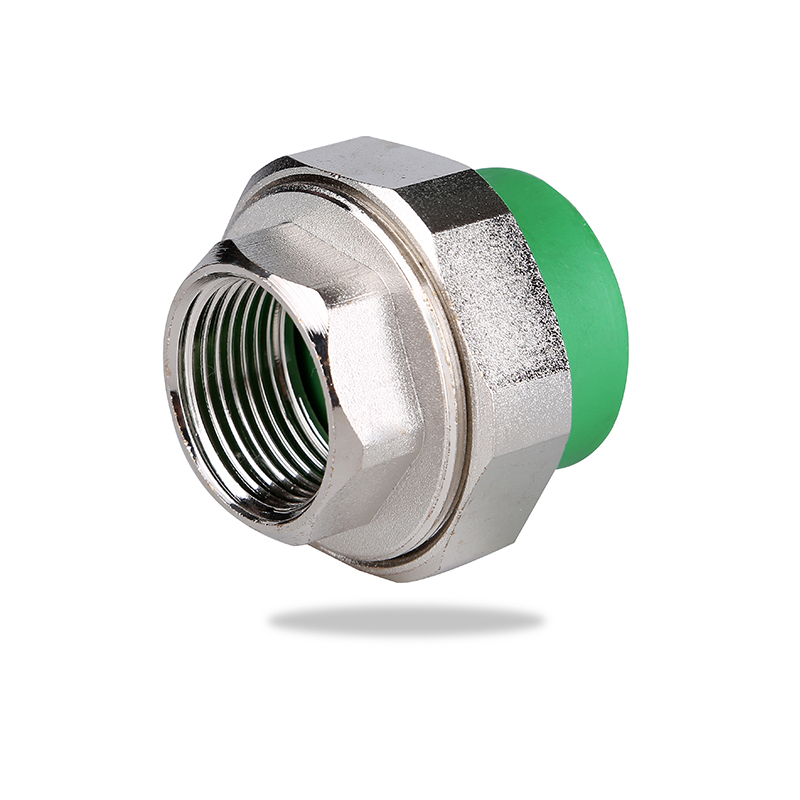

As a key connecting component in modern building water supply systems, PPR Union's sealing and stability directly affect the safe operation of the entire pipeline system. The implementation of these properties largely depends on the physical and chemical properties of the PPR material used. This article will analyze how PPR Union achieves good sealing and structural stability through material properties from a material perspective.

1、 The basic composition and structural advantages of PPR materials

PPR (Polypropylene Random Polymer) is a polymer material formed by randomly embedding ethylene monomers into propylene as the main chain. This molecular structure endows PPR material with excellent heat resistance, creep resistance, and chemical stability, making it an ideal choice as a hot water pipe and connector.

Compared to traditional PE or PVC materials, PPR has higher crystallinity and more uniform molecular chain distribution, which enables PPR Union to maintain a stable structural morphology under long-term pressure and temperature changes, and is less prone to deformation or cracking.

2、 Excellent hot melt performance ensures sealed connection

PPR material has good hot melt properties, which is one of the key factors for achieving sealing. During the installation process, PPR Union and PPR pipes are heated to around 260 ℃ using specialized hot melt tools and quickly connected, forming an integrated connection structure during the cooling process.

Due to the good fluidity and adhesion of PPR material in the molten state, it can fully fill the interface gap and form a seamless fusion sealing layer, thereby avoiding the problems of rubber gasket aging and loosening that are common in traditional metal joints, leading to leakage. This "self sealing" connection method enables PPR Union to have extremely high sealing reliability.

3、 Creep resistance ensures long-term structural stability

The creep resistance of materials is crucial in a continuously pressurized pipeline system. PPR material has excellent creep resistance, and can maintain its shape for a long time even at high temperatures of 70 ℃ and working pressures above 1MPa, without loosening or leaking at the connection due to stress relaxation.

This feature is particularly suitable for hot water systems and underfloor heating projects, ensuring the long-term stability of PPR Union under complex working conditions and effectively extending the service life of the entire pipeline system.

4、 Corrosion resistance and non-toxic environmental protection enhance the safety of use

PPR material itself has good chemical inertness, does not react with common ions in water, and will not cause corrosion, scaling and other problems due to long-term contact with water medium. Therefore, PPR Union can still maintain good performance in acidic and alkaline environments or chlorine containing disinfectant water, further improving its sealing and durability.

In addition, PPR material is non-toxic and harmless, and meets the standards for drinking water transportation (such as GB/T 18742, ISO 15874, etc.). It is widely used in cold and hot water systems in households and public buildings, ensuring the safety of water use for users.

5、 Moderate coefficient of thermal expansion, reducing the risk of stress failure

The linear expansion coefficient of PPR material is about 0.15 mm/(m ·℃), which is higher than that of metal materials but much lower than that of ordinary plastics. Under reasonable design, combined with appropriate bracket fixation and compensation measures, PPR Union can effectively cope with thermal expansion and contraction caused by temperature changes, avoiding interface cracking or sealing failure due to thermal stress concentration.

PPR Union can achieve good sealing and structural stability mainly due to the excellent hot melt resistance, creep resistance, corrosion resistance, and moderate thermal expansion coefficient of PPR materials themselves. These material properties not only ensure its reliable connection performance under various working conditions, but also make it an indispensable key component in modern building water supply systems. With the development of materials science, PPR Union still has significant room for improvement in performance optimization and application scenario expansion in the future.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie