PPR Tee, also known as Polypropylene Random Copolymer Tee, is a widely used piping component in plumbing, heating, and industrial piping systems. It serves as a crucial connector, allowing the diversion or branching of fluid flow within a pipeline. One common question among engineers, installers, and homeowners is whether PPR Tee can withstand high temperature and high pressure conditions. Understanding the capabilities and limitations of PPR Tee is essential for safe, reliable, and long-lasting piping installations.

Material Properties of PPR Tee

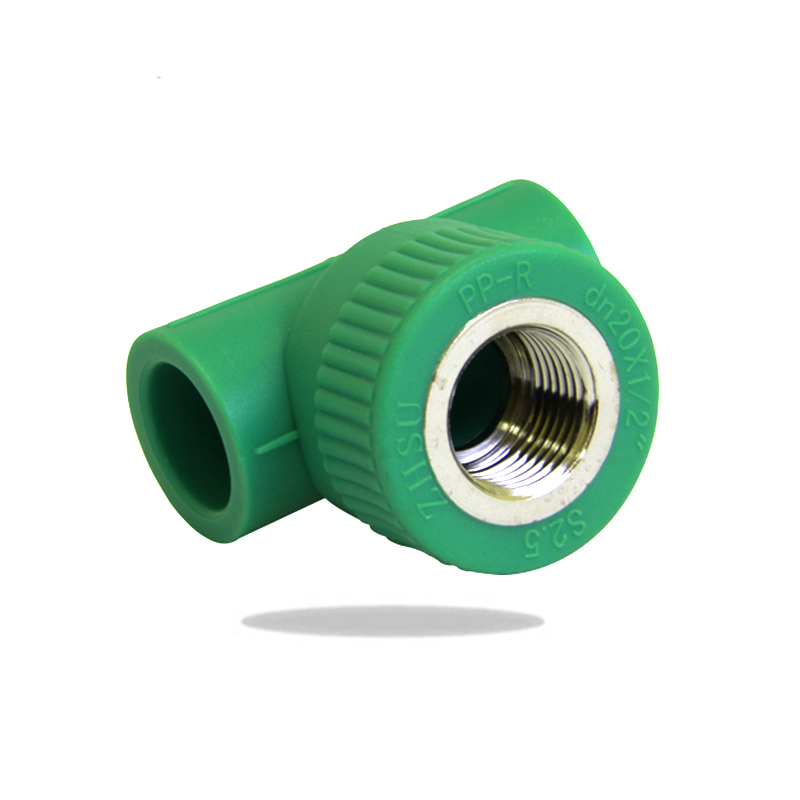

PPR pipes and fittings, including tees, are made from polypropylene random copolymer (PPR). This material is known for its excellent chemical resistance, smooth inner surface, and thermal stability. Compared to traditional PVC or metal pipes, PPR offers superior resistance to corrosion, scaling, and most chemicals commonly transported in domestic or industrial piping systems.

The material properties directly influence the ability of a PPR Tee to handle high temperatures and pressures. PPR has a maximum continuous operating temperature of approximately 70°C to 90°C (158°F to 194°F), depending on the specific grade and manufacturer specifications. Some high-temperature grades can withstand short-term exposure to temperatures up to 95°C to 100°C (203°F to 212°F).

Pressure Rating and Performance

PPR Tees are manufactured with specific pressure ratings, often denoted as PN (Pressure Nominal) values, such as PN10, PN16, or PN20, representing the maximum operating pressure in bars at 20°C. For example, a PN20 PPR Tee can safely operate at 20 bars (approximately 290 psi) at room temperature. However, it is important to note that the allowable pressure decreases as the temperature rises. At elevated temperatures, the material softens slightly, reducing its ability to resist internal pressure. Manufacturers typically provide derating charts showing maximum allowable pressures at different temperatures to ensure safe operation.

Factors Affecting High-Temperature and High-Pressure Performance

Several factors influence whether a PPR Tee can withstand high temperature and high pressure conditions:

- Wall Thickness: Heavier or thicker-walled PPR Tees can endure higher pressures and temperature fluctuations. Choosing the correct schedule or wall thickness is essential for system safety.

- Installation Quality: Proper fusion welding of the PPR Tee to the pipe is critical. Poor welding or uneven heating can create weak points that fail under pressure or heat.

- Environmental Conditions: Continuous exposure to sunlight, UV radiation, or chemicals may reduce the mechanical strength of PPR over time. While PPR is generally chemically resistant, extreme conditions should be considered in system design.

- System Design: The overall system, including elbows, bends, and tees, should be designed to minimize stress concentration points. Rapid temperature changes or excessive internal pressure surges can affect the durability of PPR fittings.

Applications and Limitations

PPR Tees are widely used in hot and cold water plumbing, underfloor heating, and industrial fluid transport. They are suitable for hot water systems at temperatures up to 70°C to 90°C and pressures up to their rated PN value. For higher-temperature applications, specialized high-temperature PPR grades or alternative materials such as PEX, CPVC, or metal fittings may be required.

While PPR Tee performs well in most residential and commercial applications, it is not recommended for steam lines or continuous operation above its maximum rated temperature. High-pressure industrial systems involving extreme heat may require reinforced materials or metal tees to ensure safety.

Maintenance and Safety Tips

To maximize the lifespan of PPR Tees under high-temperature and high-pressure conditions:

- Always adhere to manufacturer specifications for pressure and temperature limits.

- Avoid sudden pressure surges or thermal shocks.

- Ensure proper installation using recommended fusion welding techniques.

- Inspect periodically for leaks, deformation, or discoloration that may indicate material stress.

- Consider derating the system pressure at elevated temperatures to maintain a safety margin.

Conclusion

In conclusion, PPR Tee can withstand moderately high temperatures and pressures within the limits specified by manufacturers. Its polypropylene random copolymer construction provides excellent thermal and chemical stability, making it suitable for most domestic and commercial hot water systems. However, the performance of a PPR Tee depends on several factors, including wall thickness, quality of installation, system design, and environmental conditions. For extreme applications involving very high temperatures or pressures, alternative materials may be more appropriate. By following proper installation procedures, adhering to rated specifications, and maintaining the system, PPR Tees can provide reliable and long-lasting service in high-temperature and high-pressure piping systems.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie