In the intricate dance of plumbing systems, finding components that seamlessly i...

READ MOREPPR Unequal Elbow

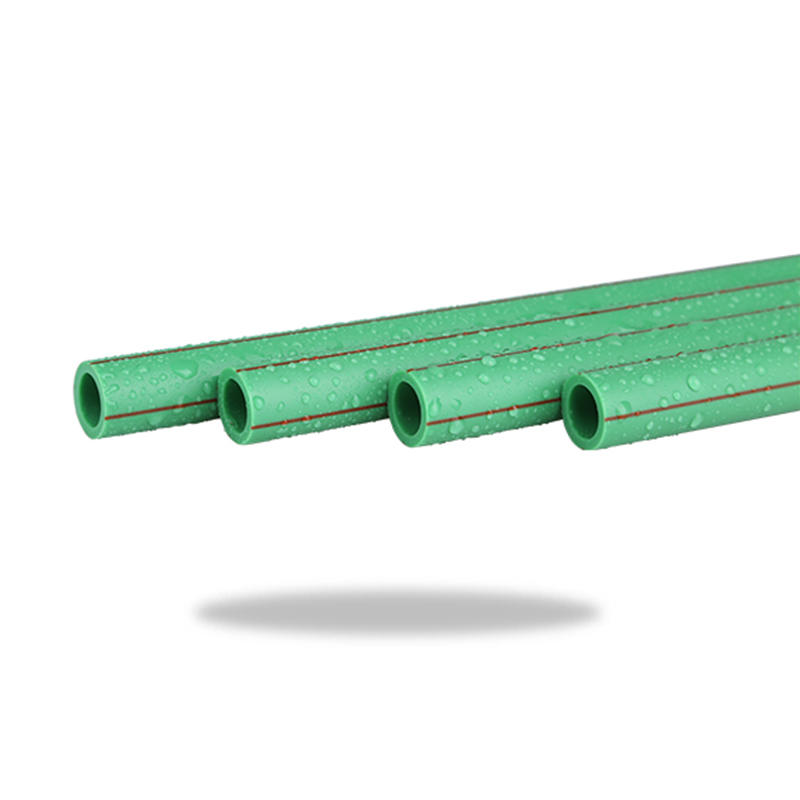

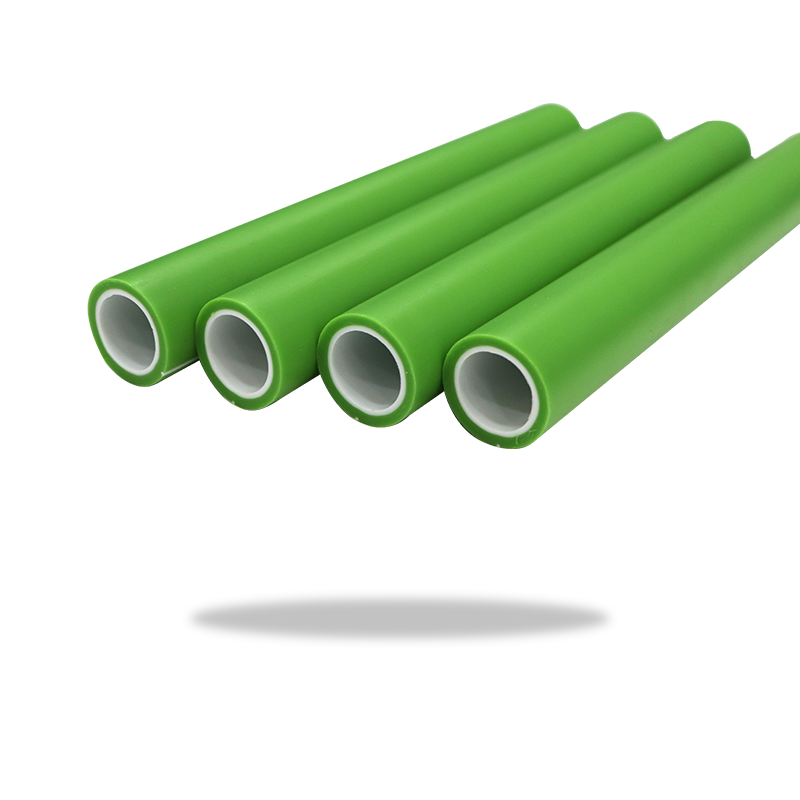

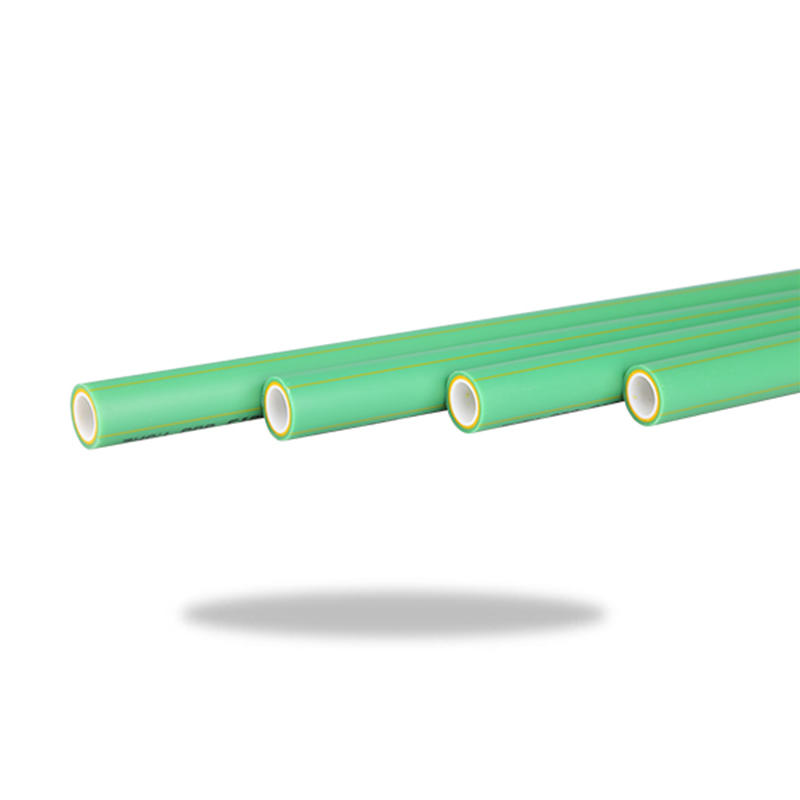

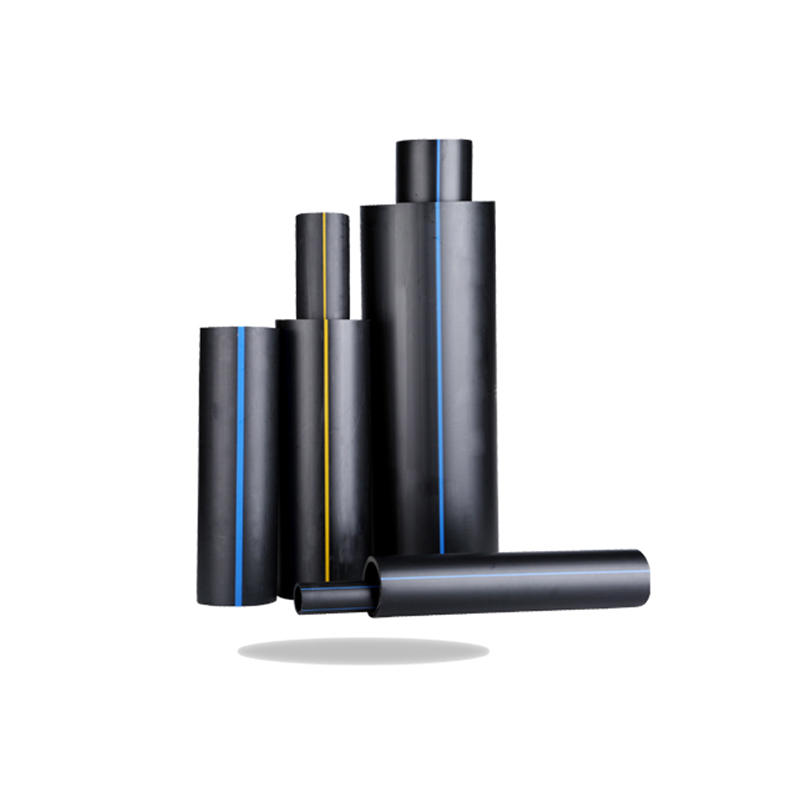

Shanghai Zhongsu Pipe Co.,Ltd established in 2004 with 1.01 billion registration capital, situated in Jinshan district of shanghai china, occupied 70000 square meters. ZHSU specialized in producing PPR pipe, antibacterial PPR pipe, anti UV PPR pipe, PP-RCT pipe, PE-RT pipe, HDPE pipe and fittings with various materials, adopted high technology production line to improve productivity and provide customer with fast delivery time. OEM PPR Unequal Elbow Manufacturers and Wholesale PPR Unequal Elbow Factory in China. In order to cooperate with national rural drinking water safety project, ZHSU adopted large diameter facility for PE production, our biggest PE pipe diameter reached DN1200mm at present, ZHSU has become one of the manufacturers in china who can produce such large diameter PE pipe.

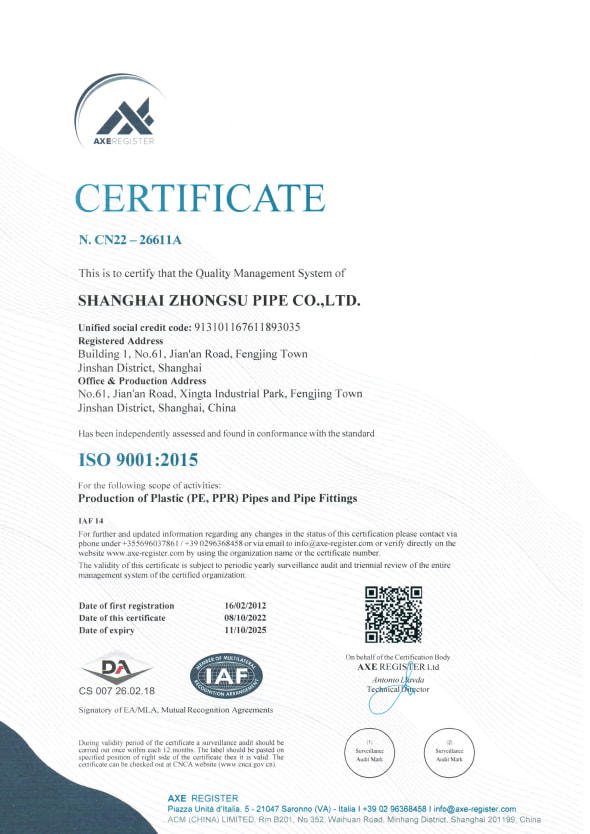

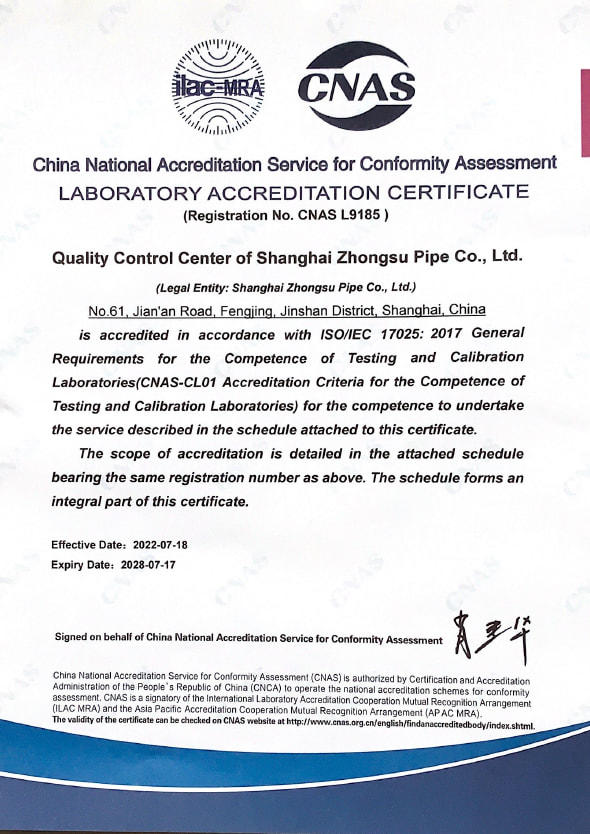

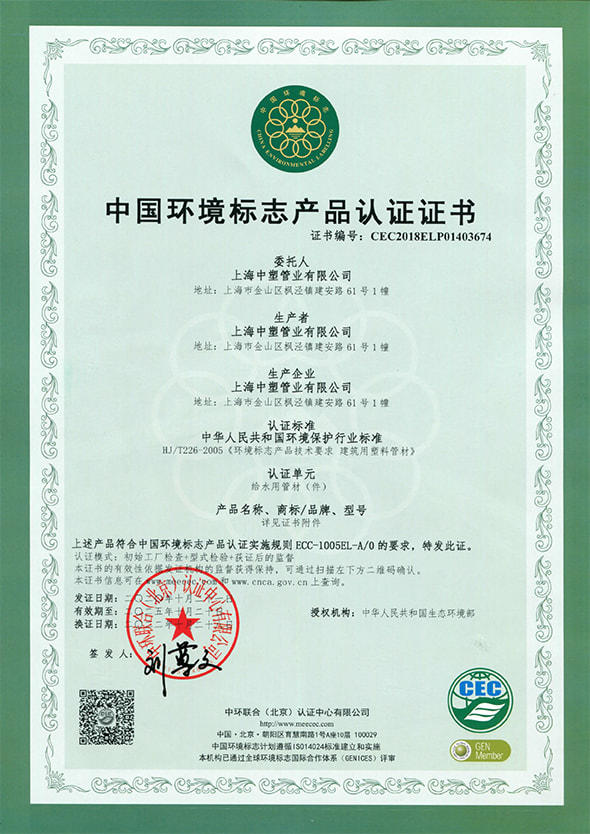

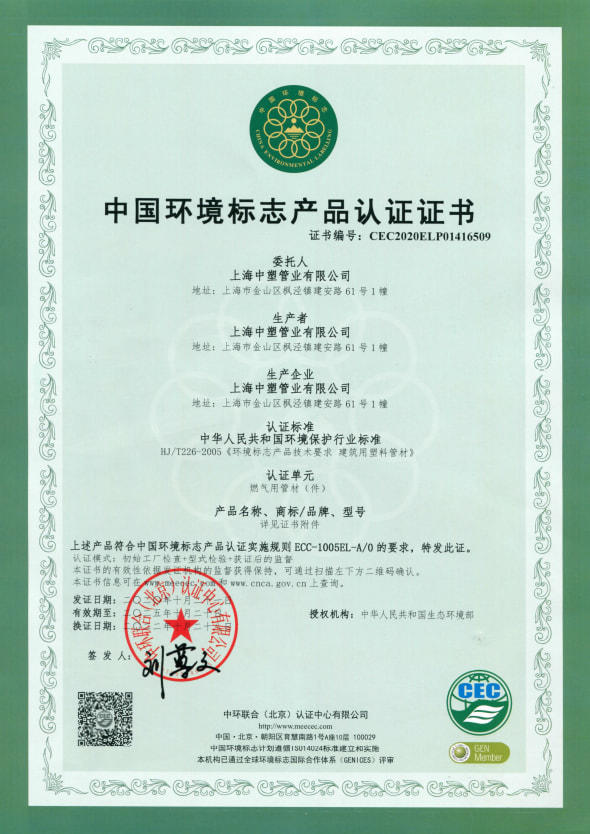

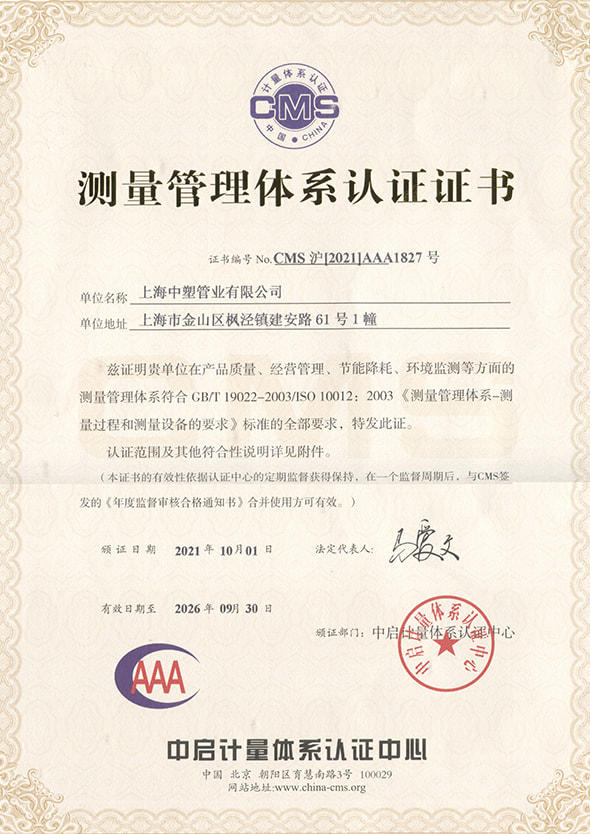

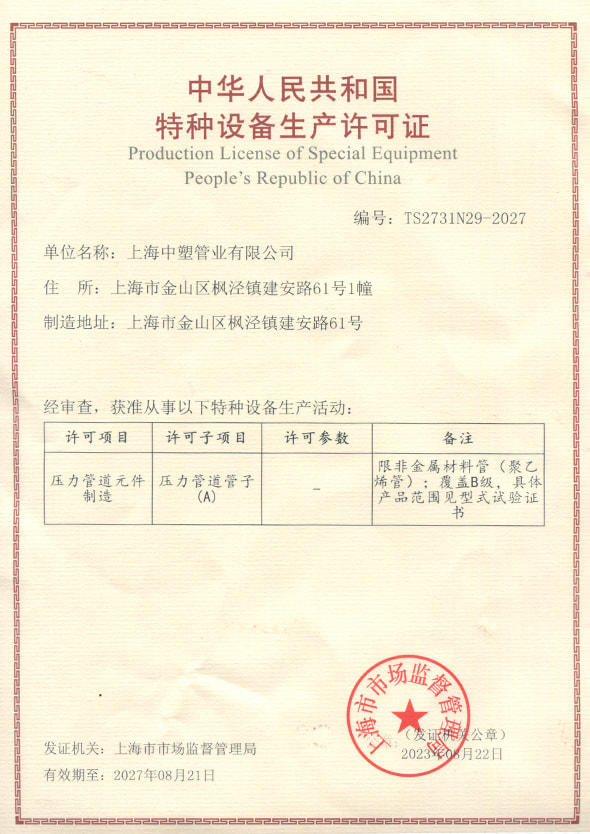

We adopted German brand Battenfeld-cincinnati production lines for plastic pipes to organize production in strictly accordance with international standards, the procedure from raw material purchasing to finished product delivery is fully under monitoring, passed ISO9001, ISO14001 and OHSAS18001 certification because of perfect management. Wholesale PPR Unequal Elbow. Besides we were nominated as ”Shanghai famous brand products, Shanghai high-tech enterprises and Shanghai famous trademarks”.

-

-

When need to choosing pipes for various applications, one of the critical factor...

READ MORE -

Polypropylene random copolymer (PPR) fittings have gained significant popularity...

READ MORE -

PPR (Polypropylene Random Copolymer) pipes have long been favored in plumbing sy...

READ MORE -

PPR (Polypropylene Random Copolymer) antimicrobial pipes have emerged as a cutti...

READ MORE

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português