How does the modified crystallinity and temperature resistance contribute to the overall performance of PP-RCT pipes?

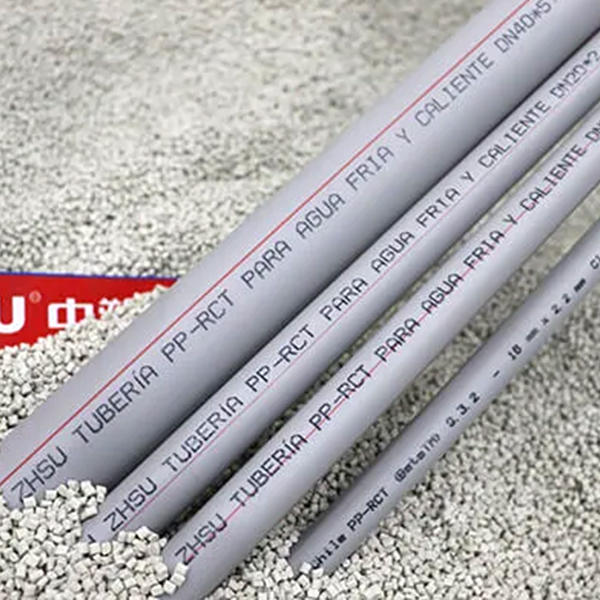

The modification of crystallinity and the enhanced temperature resistance in

PP-RCT pipes contribute significantly to their overall performance. Here's how these features impact the performance of PP-RCT pipes:

Improved Temperature Resistance:

PP-RCT pipes are designed to withstand higher temperatures compared to traditional PP-R (Polypropylene Random Copolymer) pipes. The modified crystallinity contributes to increased heat resistance, allowing PP-RCT pipes to handle higher temperature fluids in both hot water and industrial applications.

Extended Service Life:

The enhanced temperature resistance and modified crystallinity contribute to the overall durability and longevity of PP-RCT pipes. They can maintain their structural integrity and mechanical properties over an extended service life, even when exposed to elevated temperatures.

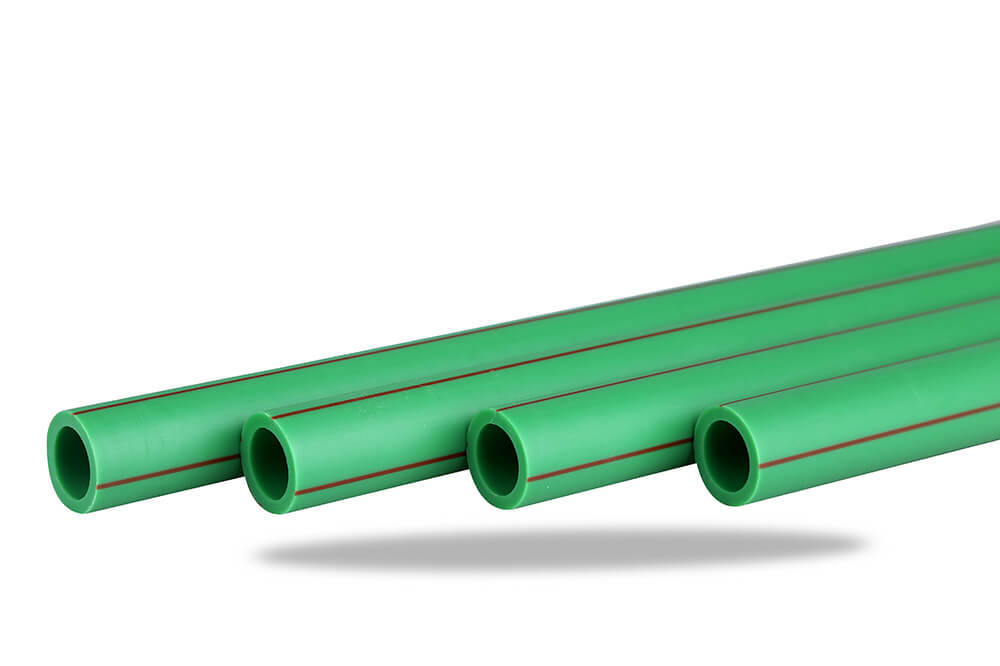

Higher Pressure Handling Capability:

The improved temperature resistance often correlates with an increased capability to handle higher pressures. PP-RCT pipes can maintain their strength and dimensional stability even in applications where both temperature and pressure levels are elevated.

Reduced Thermal Expansion:

The modified crystallinity in PP-RCT pipes helps reduce thermal expansion compared to standard PP-R pipes. This property is beneficial in plumbing and piping systems where minimizing expansion and contraction due to temperature variations is important for system integrity.

Enhanced Chemical Resistance:

The modification of crystallinity can enhance the chemical resistance of

Beta PPR Pipe. This makes them more resilient to the potential effects of chemicals or aggressive substances that may be present in the conveyed fluids.

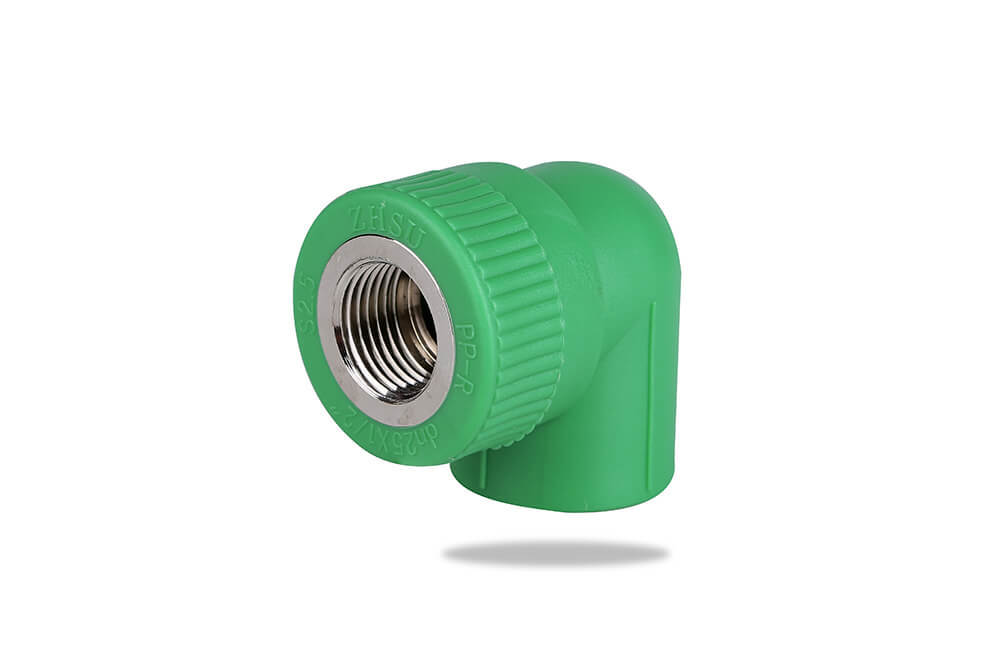

Improved Impact Strength:

The modified crystallinity can contribute to improved impact resistance, making PP-RCT pipes more robust and less susceptible to damage from external forces or mechanical stress during handling, transportation, or installation.

Ease of Installation:

PP-RCT pipes, with their improved temperature resistance and modified crystallinity, often maintain their form and ease of handling during installation. This can lead to smoother and more straightforward installation processes, reducing the likelihood of handling-related issues.

Compatibility with Various Applications:

The enhanced temperature resistance and modified crystallinity make PP-RCT pipes suitable for a broader range of applications, including those involving higher temperatures and more demanding conditions. This versatility expands the scope of applications for PP-RCT piping systems.

Consistent Material Properties:

The modification of crystallinity helps ensure consistent material properties throughout the pipe, resulting in uniform performance characteristics. This contributes to the predictability and reliability of

Beta PP-RCT pipes in different operating conditions.

Resistance to Environmental Factors:

PP-RCT pipes exhibit resilience to environmental factors such as sunlight, UV radiation, and weathering. The modified crystallinity helps maintain the structural and functional properties of the pipes when exposed to external elements.

The combination of modified crystallinity and enhanced temperature resistance in

Beta PPR Pipe improves their overall performance by providing durability, extended service life, increased temperature handling capability, and versatility for various applications. These features make PP-RCT pipes a suitable choice for plumbing, heating, and industrial piping systems where reliability under challenging conditions is crucial.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português