Do Potable Water PPR Pipes have features to resist bacterial growth or biofilm formation within the pipes?

Potable Water PPR Pipes are designed with features to resist bacterial growth and minimize biofilm formation within the pipes. The inherent properties of the PPR material, along with the smooth inner surface of the pipes, contribute to creating an environment that is less conducive to bacterial colonization. Here are some factors that help resist bacterial growth and biofilm formation in Potable Water PPR Pipes:

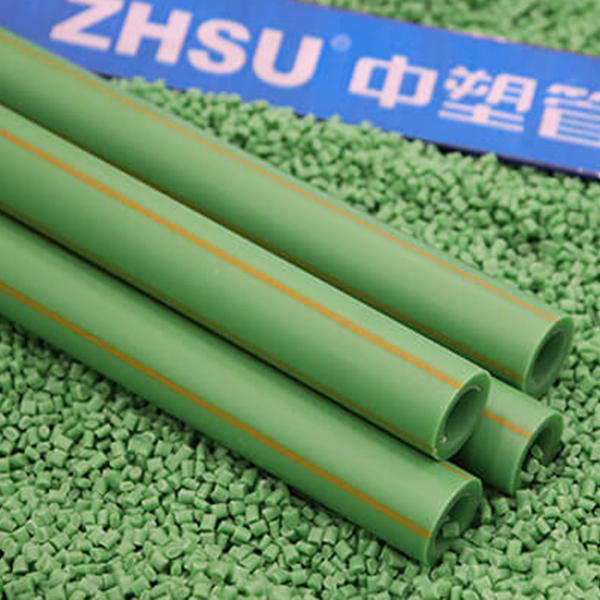

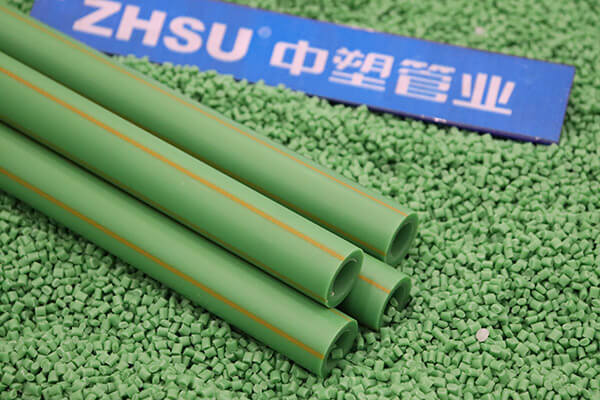

Smooth Inner Surface:

PPR Pipe for Potable Water typically have a smooth inner surface, which inhibits the attachment of bacteria and other microorganisms. The smooth surface reduces the likelihood of biofilm formation, making it more challenging for bacteria to adhere to the pipe walls.

Inherent Hygienic Properties:

The material properties of PPR contribute to its inherent hygienic characteristics. PPR is known for being resistant to scaling, corrosion, and chemical attacks, which helps maintain a clean and sanitary interior surface over time.

Resistance to Chemical Degradation:

PPR is resistant to chemical degradation, ensuring that the material itself does not break down and provide a nutrient source for bacteria. This resistance contributes to the long-term stability of the pipe material and discourages bacterial growth.

Non-Toxic and Non-Corrosive:

PPR is non-toxic and non-corrosive, ensuring that the material does not release harmful substances into the water that could promote bacterial growth. This characteristic is crucial for maintaining water quality in potable water systems.

High Purity and Low Extractables:

PPR is manufactured with high purity standards, resulting in low extractables from the material. Low extractables mean that there are fewer substances that can leach into the water, reducing the potential for bacterial support.

Resistance to Organic and Inorganic Contaminants:

The resistance of PPR to organic and inorganic contaminants further contributes to the prevention of conditions that would support bacterial growth. The material's inert nature helps maintain water purity.

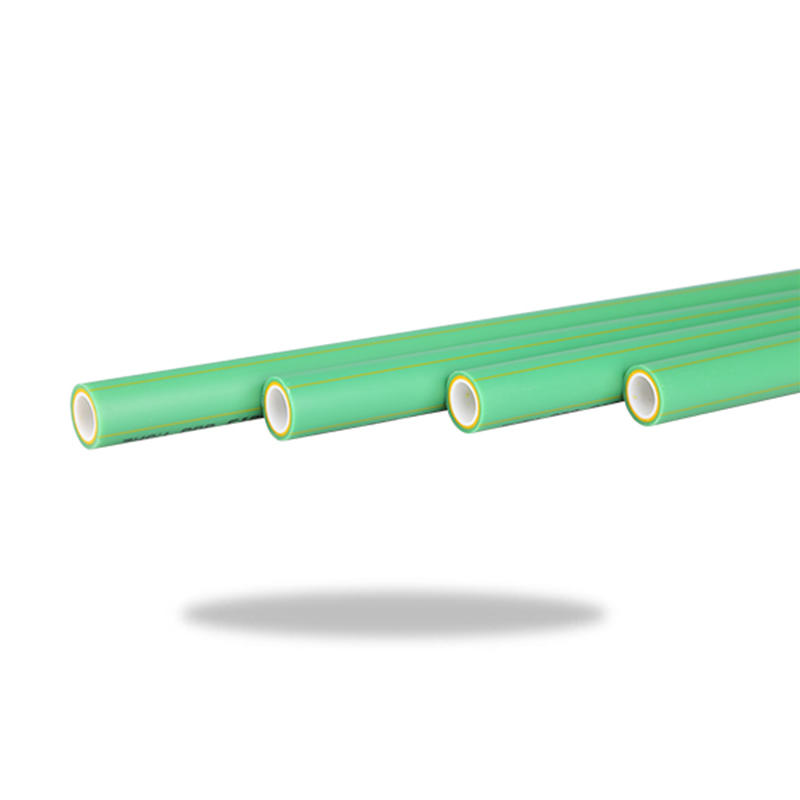

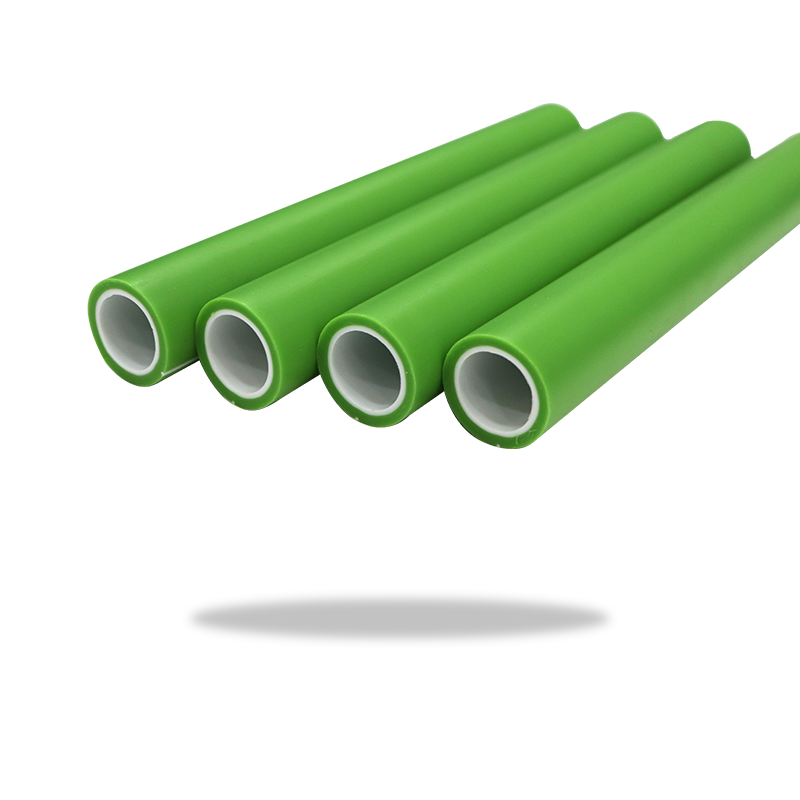

Biofilm Resilience:

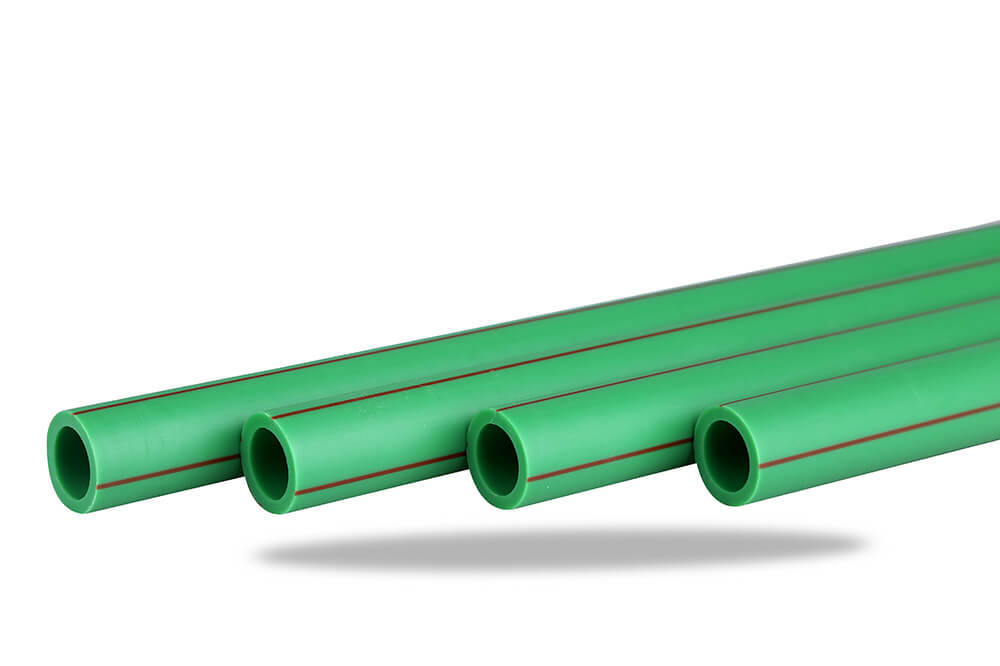

The smooth surface of

Hot Water PPR Pipe makes it more challenging for biofilms to adhere and thrive. Even if biofilms do form, the resilience of PPR against chemical degradation and scaling makes it easier to remove or prevent their buildup through standard cleaning procedures.

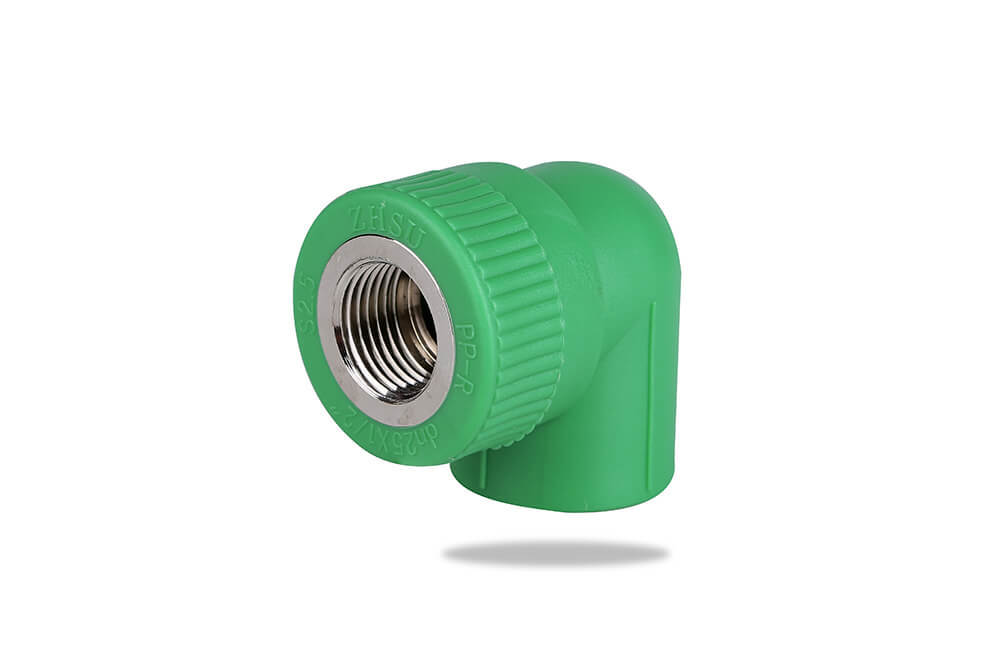

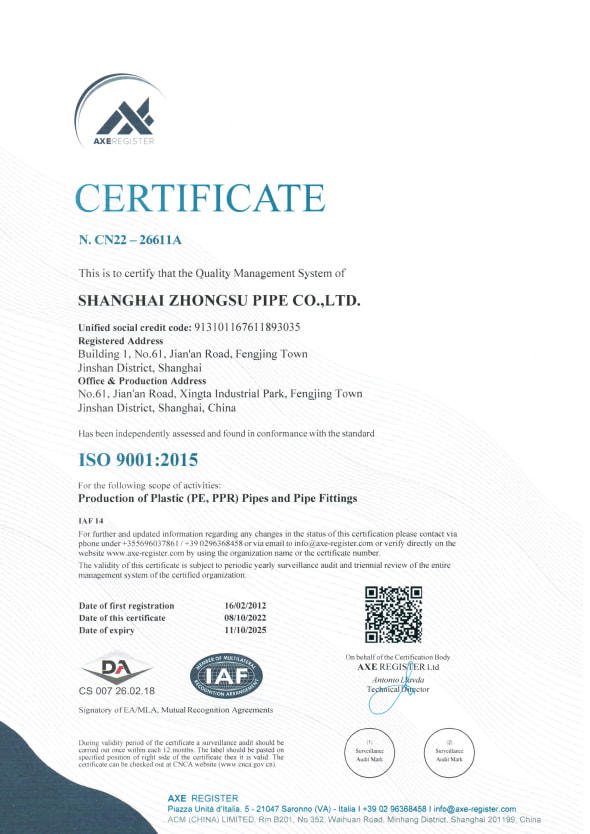

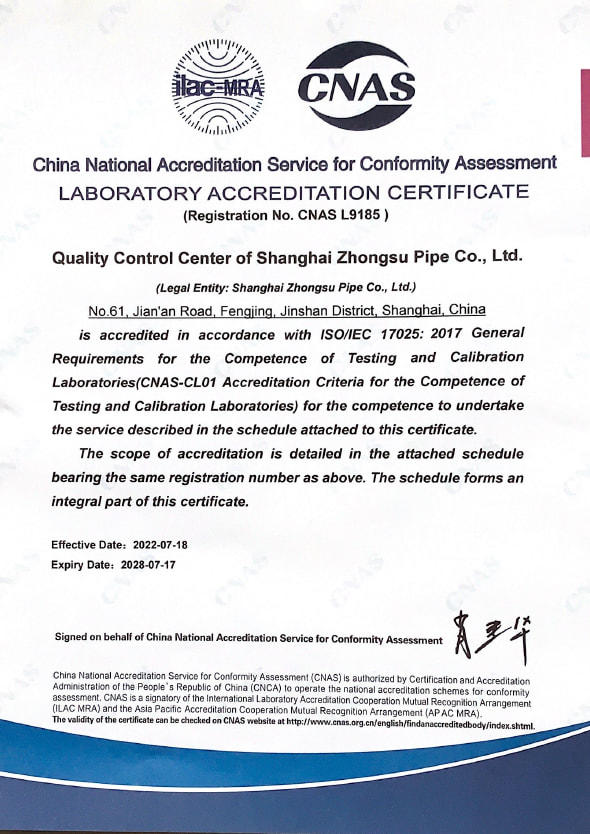

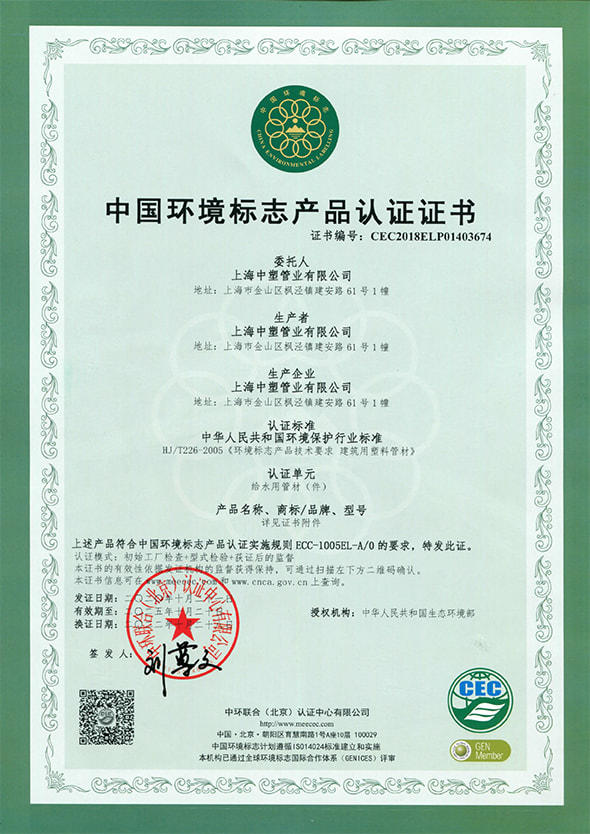

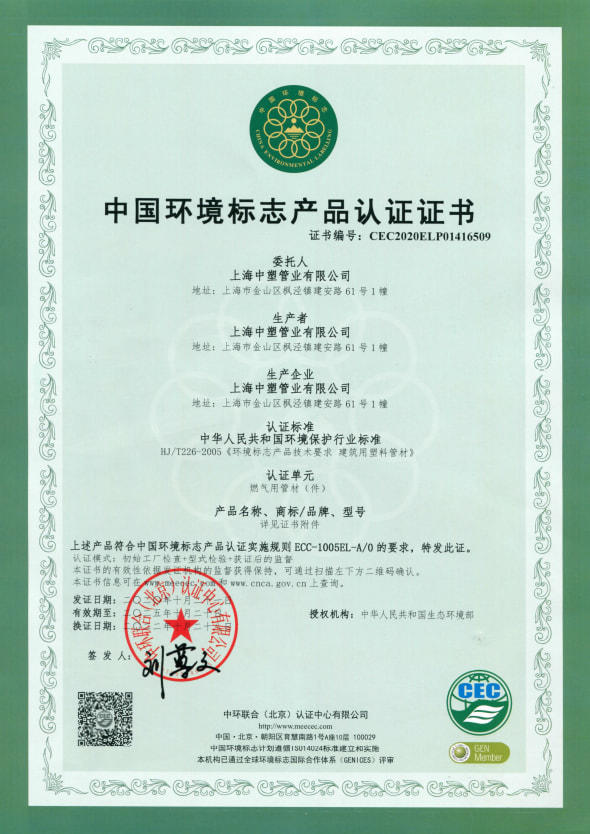

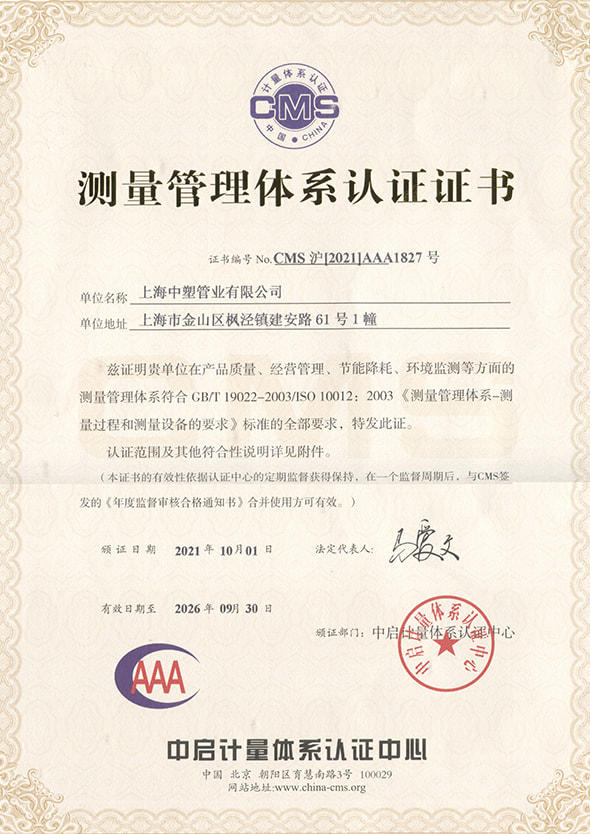

Compliance with Standards:

PPR Cold Water Pipe are often designed and manufactured to comply with health and safety standards, including those related to water quality. This compliance ensures that the pipes are suitable for use in potable water systems without compromising water hygiene.

While

PPR Hot and Cold Water Pipe offer resistance to bacterial growth and biofilm formation, proper maintenance and adherence to recommended installation practices are crucial to maximizing these benefits. Regular flushing, cleaning, and monitoring of potable water systems help ensure the ongoing integrity and hygienic performance of PPR Pipes in delivering safe drinking water.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português