How does the material composition contribute to the suitability of HDPE for gas applications?

The material composition of HDPE (High-Density Polyethylene) contributes significantly to its suitability for gas applications. Here are key ways in which the material composition makes

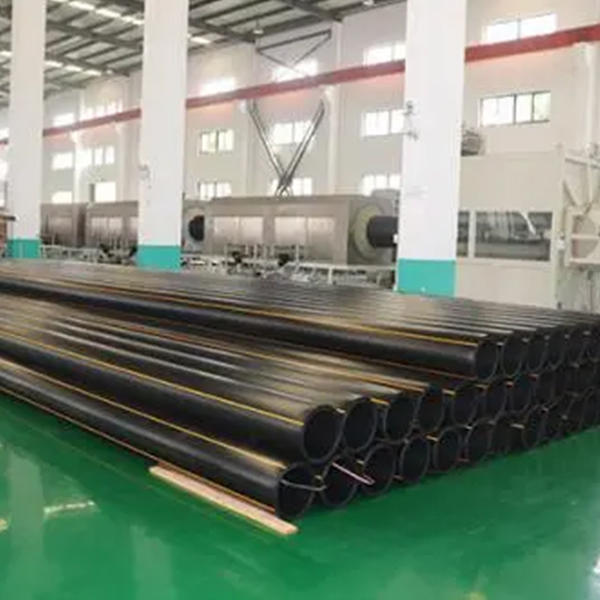

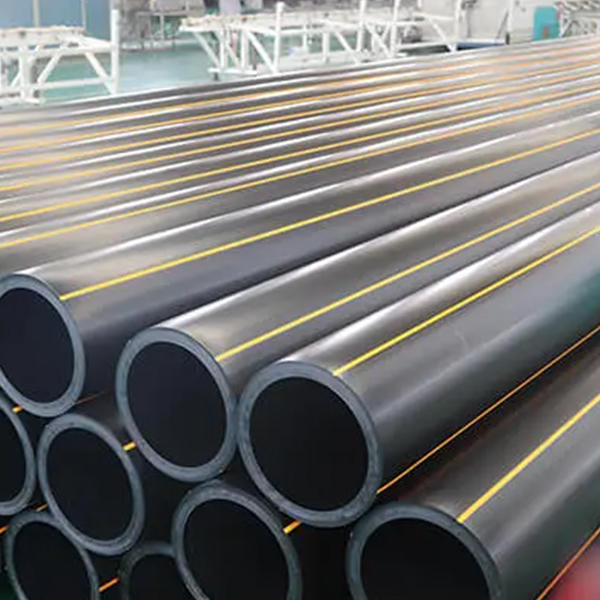

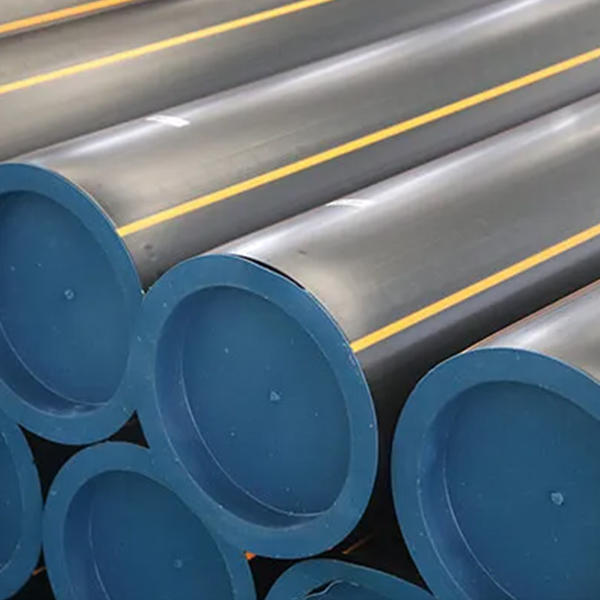

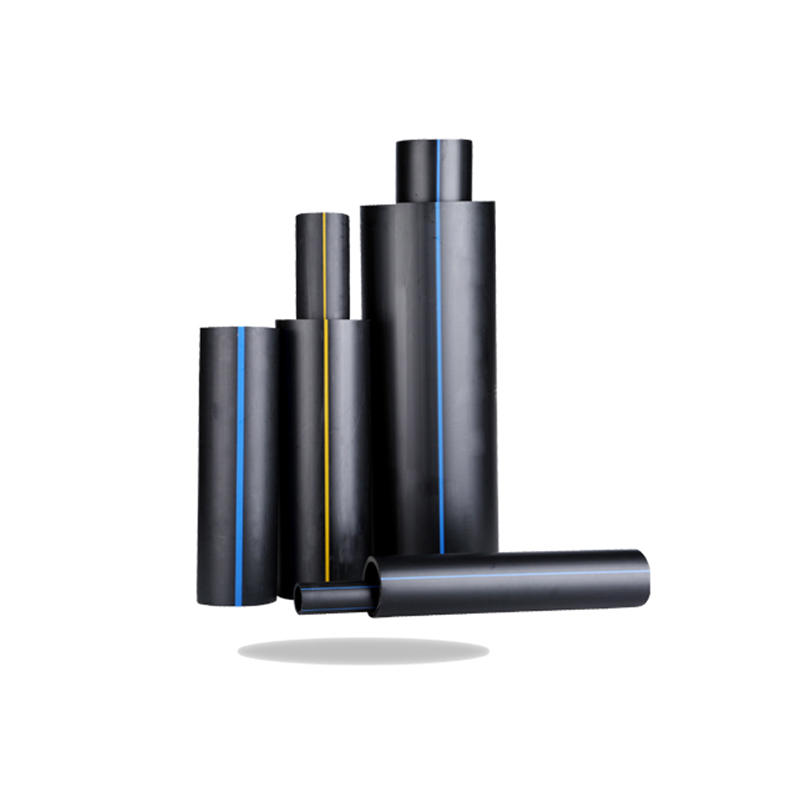

HDPE Pipe for Underground Oil & Gas Gathering systems:

Chemical Inertness:

HDPE is chemically inert, meaning it does not react with or corrode in the presence of gases. This property is crucial for ensuring the integrity of the gas distribution system and preventing contamination of the gas.

Low Permeability:

HDPE has low permeability to gases, minimizing the likelihood of gas leakage through the pipe walls. This characteristic is essential for maintaining the efficiency and safety of gas distribution networks.

Resistance to Cracking and Brittle Fracture:

HDPE exhibits excellent resistance to cracking and brittle fracture, providing durability and resistance to stress-related failures. This is particularly important in environments where the pipe may be subjected to external forces or ground movement.

Flexibility:

HDPE is a flexible material, allowing for the manufacture of coiled pipes and facilitating ease of installation. The flexibility is beneficial for navigating obstacles and adapting to the contours of the terrain during installation.

High Strength-to-Weight Ratio:

HDPE possesses a high strength-to-weight ratio, offering strength and structural integrity without excessive weight. This feature contributes to the overall robustness of the gas distribution system while maintaining ease of handling during installation.

UV Resistance:

Some HDPE formulations incorporate UV stabilizers, enhancing the material's resistance to ultraviolet (UV) radiation. This is particularly relevant for pipes exposed to sunlight during above-ground installations, ensuring long-term performance in outdoor environments.

Smooth Inner Surface:

HDPE Natural Gas Pipe typically have a smooth inner surface, reducing friction and facilitating the efficient flow of gases. The smooth surface minimizes energy losses and helps maintain the intended pressure within the gas distribution system.

Wide Temperature Range:

HDPE pipes can withstand a broad temperature range, making them suitable for gas applications that may involve variations in temperature. The material maintains its mechanical properties across a spectrum of operating temperatures.

Ease of Fusion Welding:

HDPE pipes can be joined using fusion welding techniques.

Fusion Weld Gas HDPE Pipe. The material's composition allows for a homogenous fusion at the joint, creating a strong, leak-free connection. Fusion welding is essential for maintaining the gas-tight integrity of the distribution system.

Resistance to Environmental Stress Cracking (ESC):

HDPE is resistant to environmental stress cracking, a type of cracking caused by a combination of stress and environmental factors. This resistance enhances the longevity of the material in gas distribution applications.

The material composition of HDPE, characterized by its chemical inertness, low permeability, flexibility, and other key properties, makes it highly suitable for use in gas applications. These attributes contribute to the reliability, safety, and longevity of HDPE gas distribution systems.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português