Can you explain how these ratings affect the suitability of the fittings for different applications?

Certainly! The pressure and temperature ratings of

PPR (Polypropylene Random Copolymer) Tee fittings play a crucial role in determining their suitability for different applications. Here's how these ratings affect the performance and application of the fittings:

Pressure Ratings:

Low-Pressure Applications: PPR Tee fittings with lower pressure ratings, such as PN10, are suitable for applications with relatively low operating pressures. These may include residential plumbing systems, water distribution networks, and similar setups where the pressure requirements are not exceptionally high.

Medium to High-Pressure Applications: Fittings with higher pressure ratings, such as PN16, PN20, or PN25, are designed for use in applications with elevated pressure levels. These may include industrial processes, commercial plumbing, or larger-scale water supply systems.

Temperature Ratings:

Standard Temperature Applications: PPR Tee fittings with standard temperature ratings (commonly 5°C to 95°C) are suitable for most standard plumbing applications, including hot and cold water distribution in residential and commercial buildings.

High-Temperature Applications: In situations where higher temperatures are involved, such as in industrial processes or specific applications requiring hot water circulation, PPR fittings with extended temperature resistance may be necessary. Some formulations can handle temperatures above the standard range.

Versatility and Flexibility:

Versatile Use: PPR fittings are often chosen for their versatility. They can be used in various applications, including potable water systems, heating systems, cooling systems, and even certain chemical applications due to their corrosion resistance.

Flexibility in Design: The availability of PPR Tee fittings with different pressure and temperature ratings provides flexibility in designing plumbing systems. Engineers and installers can select fittings based on the specific requirements and conditions of the application.

Compliance with Standards:

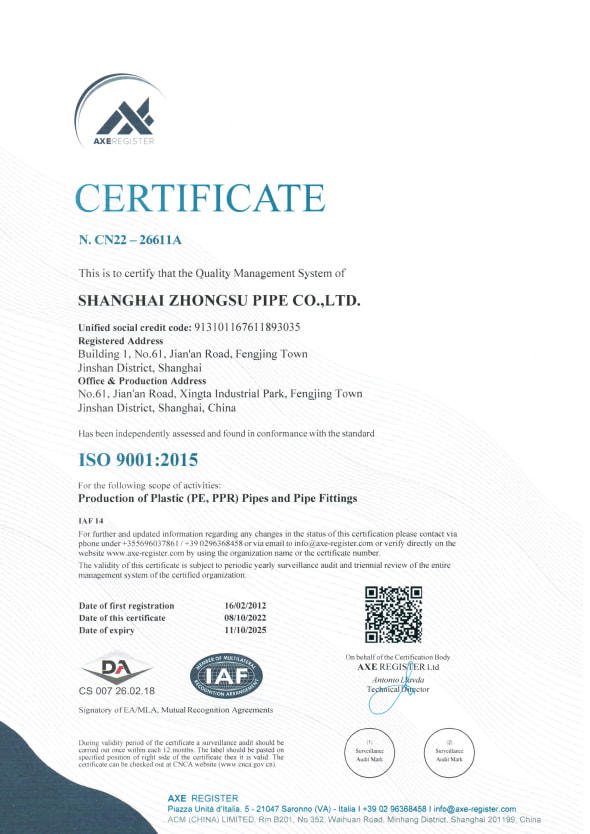

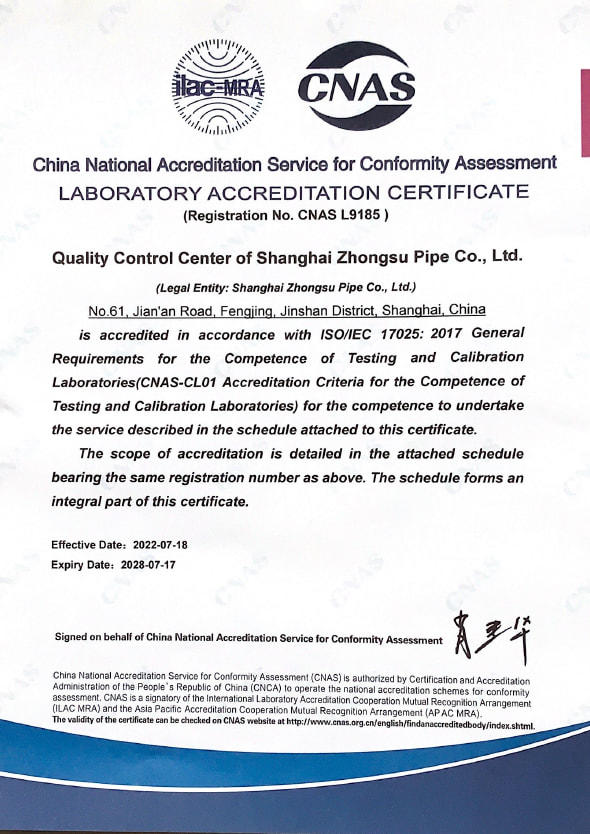

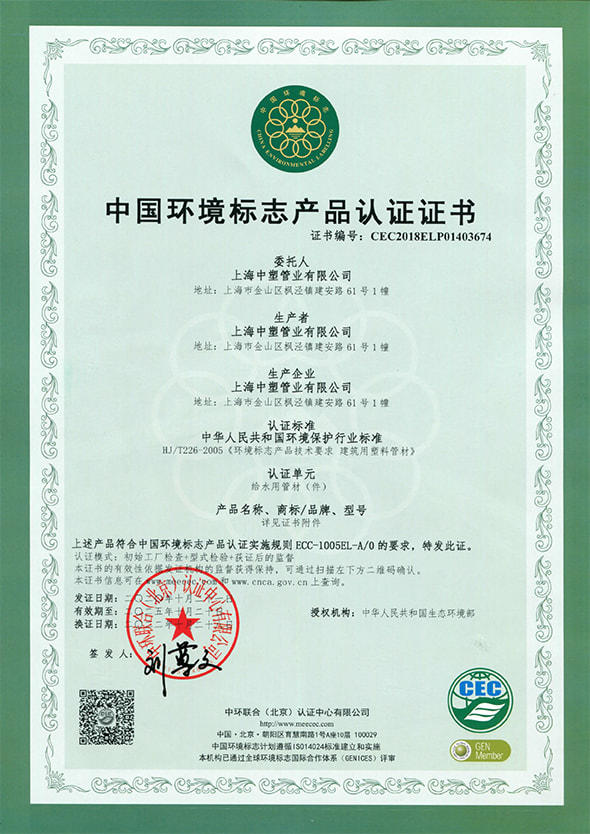

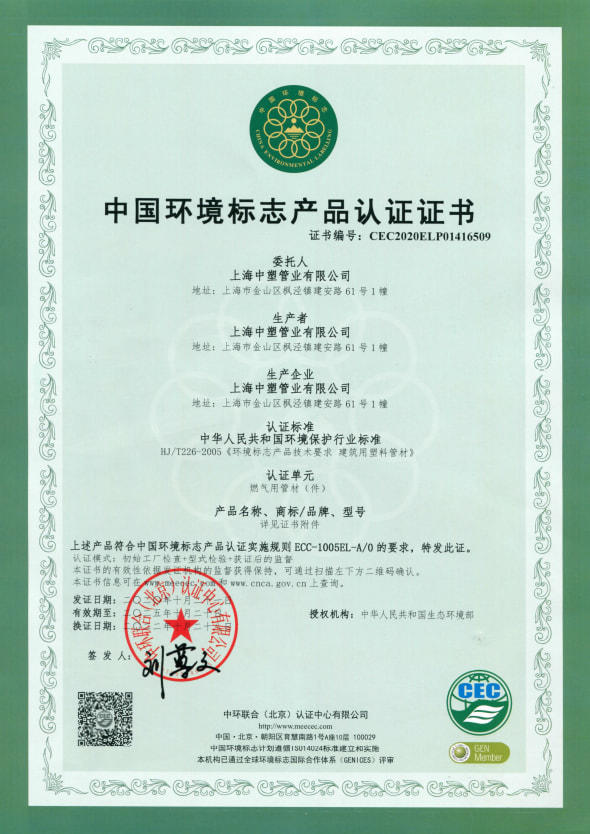

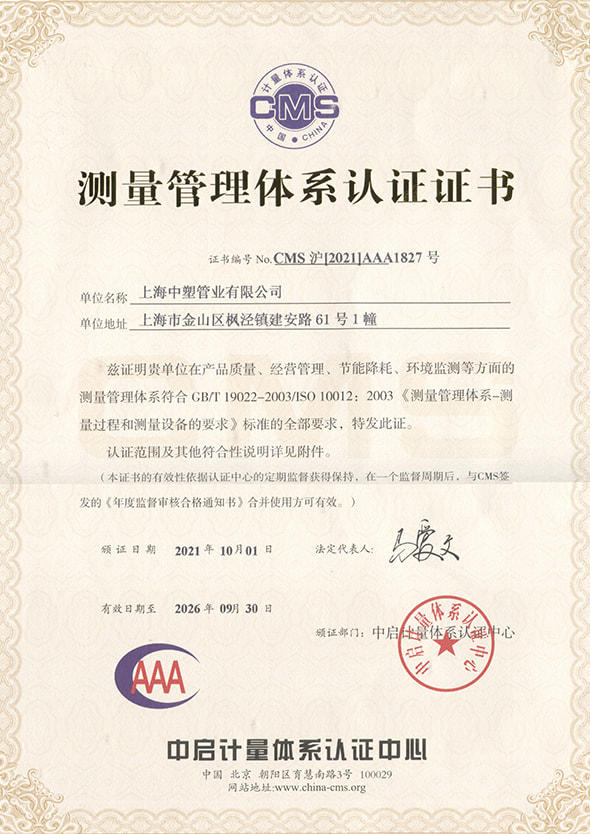

Meeting Regulatory Requirements: The pressure and temperature ratings of PPR Tee fittings must comply with relevant industry standards and local building codes. Adherence to these standards ensures that the fittings meet safety and performance criteria, making them suitable for use in specific regions or applications.

It's important for designers, engineers, and installers to carefully consider the pressure and temperature requirements of a given plumbing or piping system when selecting PPR Tee fittings. Choosing fittings with appropriate ratings ensures the integrity and reliability of the system while meeting regulatory and safety standards.

What is the manufacturing process for PPR Tee fittings?

The manufacturing process for

PPR (Polypropylene Random Copolymer) Tee fittings typically involves several steps to ensure precision, consistency, and the desired mechanical properties. Here's an overview of the general manufacturing process for PPR Tee fittings:

Material Selection:

PPR is a type of thermoplastic polymer, and its composition includes polypropylene and a random copolymer. The manufacturing process begins with the selection of high-quality PPR resin granules.

Extrusion:

The selected PPR resin is fed into an extruder, where it undergoes a melting process. The extruder applies heat and pressure to melt the resin, forming a homogenous molten material.

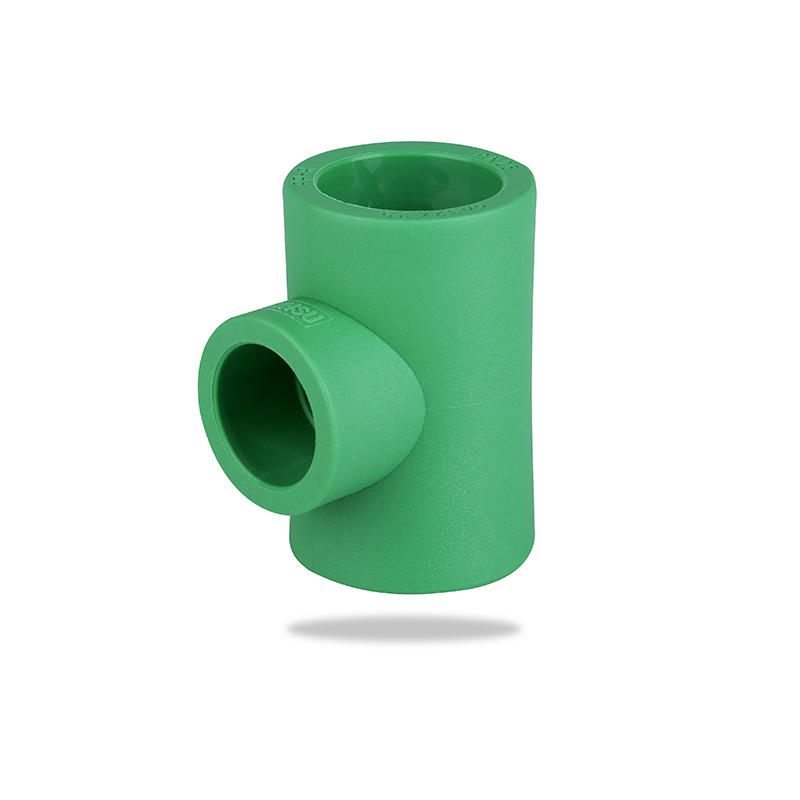

Pipe Profile Extrusion:

The molten PPR material is then passed through a die that shapes it into the profile of a Tee fitting. In the case of a Tee, the extrusion process forms the main body of the fitting, including the three branches.

Cooling:

After extrusion, the newly formed PPR Tee passes through a cooling process to solidify the material and maintain the desired shape. This is often achieved using water baths or air cooling methods.

Cutting and Sizing:

The extruded PPR profile is cut into specific lengths, corresponding to the dimensions of the Tee fittings. This step ensures uniformity and precision in the final product.

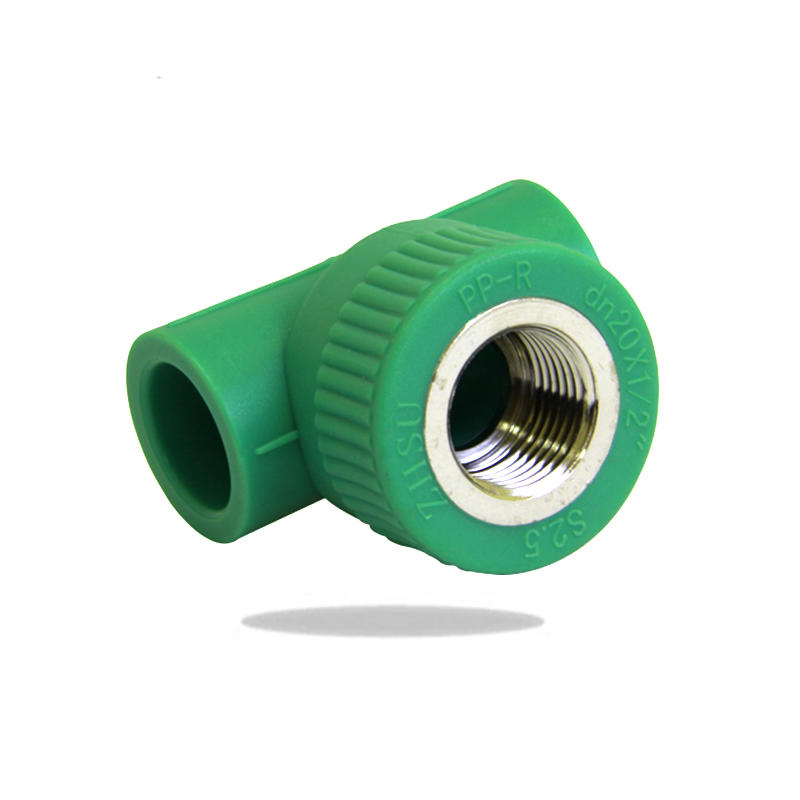

Molded Features:

If additional features, such as threads, reinforcement, or specific geometries, are required for the Tee fittings, a secondary molding process may be employed. This can involve the use of molds to shape and refine the fittings further.

Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure that the PPR Tee fittings meet the specified standards and requirements. This includes checking dimensions, pressure resistance, and other mechanical properties.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português