How does HDPE compare to other materials commonly used for pipes?

High-Density Polyethylene (HDPE) pipes are compared to various other materials commonly used for pipes based on several factors. Here's a comparison with some of the commonly used pipe materials:

HDPE vs. PVC (Polyvinyl Chloride):

HDPE:

Advantages: Greater flexibility, higher impact resistance, resistance to chemicals and UV, lightweight, better performance in cold weather.

Disadvantages: Lower temperature resistance compared to PVC.

PVC:

Advantages: Cost-effective, suitable for a wide range of applications, good chemical resistance.

Disadvantages: Less flexible, may become brittle over time, limited impact resistance.

HDPE vs. PPR (Polypropylene Random Copolymer):

HDPE:

Advantages: Better impact resistance, greater flexibility, higher temperature resistance, suitable for larger diameters.

Disadvantages: Slightly lower temperature resistance compared to PPR.

PPR:

Advantages: Better temperature resistance, smooth interior surface, corrosion-resistant.

Disadvantages: Less impact-resistant, typically used in smaller diameter applications.

HDPE vs. ABS (Acrylonitrile Butadiene Styrene):

HDPE:

Advantages: Greater flexibility, higher chemical resistance, lightweight, suitable for outdoor applications.

Disadvantages: Lower impact resistance compared to ABS.

ABS:

Advantages: Better impact resistance, suitable for low-temperature applications, smooth interior surface.

Disadvantages: Less flexible, lower chemical resistance compared to HDPE.

HDPE vs. Ductile Iron:

HDPE:

Advantages: Lightweight, flexible, resistant to corrosion and rust, easy to install, longer lifespan.

Disadvantages: Lower stiffness compared to ductile iron.

Ductile Iron:

Advantages: High stiffness, good pressure-bearing capacity, suitable for high-pressure applications.

Disadvantages: Heavier, prone to corrosion, may require cathodic protection.

HDPE vs. Concrete:

HDPE:

Advantages: Lightweight, flexible, resistant to corrosion, easy to install, suitable for trenchless installation methods.

Disadvantages: Lower pressure-bearing capacity compared to concrete.

Concrete:

Advantages: High pressure-bearing capacity, durable, resistant to external loads.

Disadvantages: Heavy, prone to corrosion of reinforcing steel, may require cathodic protection.

HDPE vs. Steel:

HDPE:

Advantages: Corrosion-resistant, lightweight, flexible, easier to handle and install, no need for corrosion protection.

Disadvantages: Lower pressure-bearing capacity compared to steel.

Steel:

Advantages: High pressure-bearing capacity, suitable for high-temperature applications, durable.

Disadvantages: Prone to corrosion, heavy, may require external corrosion protection.

The choice between materials depends on the specific requirements of the application. Factors such as cost, installation method, pressure requirements, chemical resistance, and environmental conditions play a crucial role in determining the most suitable pipe material for a given project. HDPE is often preferred for its versatility, ease of installation, and resistance to corrosion and chemicals, making it suitable for a wide range of applications.

What are the key material properties of HDPE that make it suitable for pipe applications?

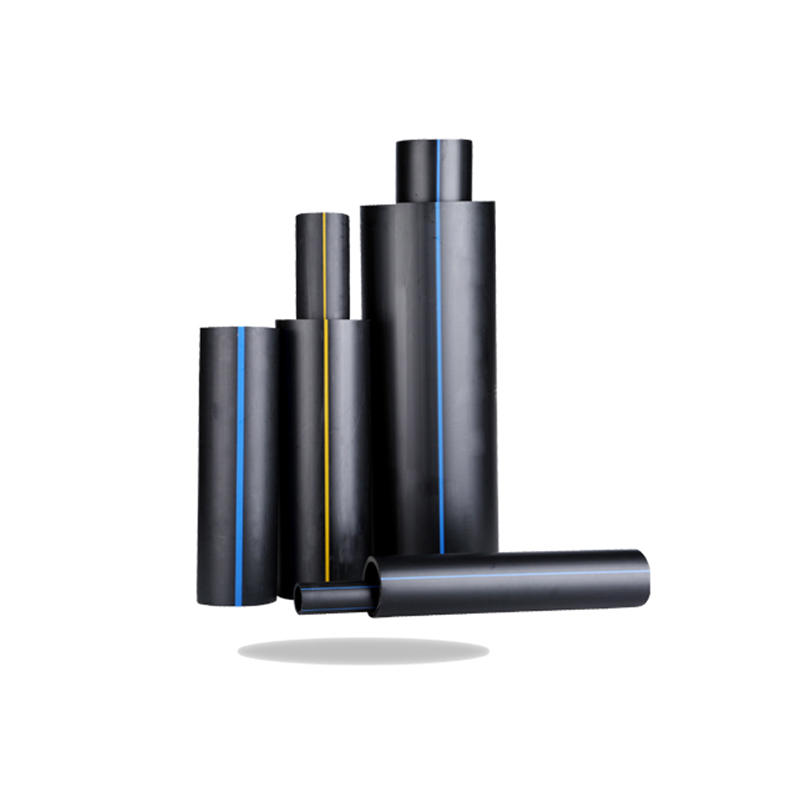

High-Density Polyethylene (HDPE) is a popular material for pipe applications due to its unique combination of material properties. The key material properties of

HDPE pipe that make it suitable for pipe applications include:

Chemical Resistance:

HDPE is highly resistant to a wide range of chemicals, making it suitable for conveying various substances without the risk of chemical degradation or corrosion.

Inert Material:

HDPE is inert to most common chemicals and does not impart any taste, odor, or color to the conveyed fluids. This property makes it ideal for transporting potable water and other sensitive liquids.

Flexibility:

HDPE pipes are flexible and have a high level of elasticity. This flexibility allows for easier installation around obstacles, reduces the need for fittings, and enables the pipe to withstand ground movement without cracking.

Toughness and Impact Resistance:

HDPE is known for its toughness and excellent impact resistance. It can absorb and distribute impact energy, making it highly durable and suitable for applications where pipes may be subjected to external forces.

Lightweight:

HDPE pipes are lightweight compared to traditional materials like metal or concrete. This characteristic simplifies transportation, handling, and installation, reducing overall project costs.

Corrosion Resistance:

HDPE is inherently resistant to corrosion and rust, making it an ideal choice for applications where exposure to corrosive substances or environments is a concern. It is particularly suitable for use in soil with aggressive corrosive properties.

Smooth Interior Surface:

HDPE pipes have a smooth interior surface that minimizes friction and provides efficient fluid flow. This smoothness contributes to reduced energy consumption and lowers pumping costs.

UV Resistance:

HDPE exhibits excellent resistance to ultraviolet (UV) radiation. This property makes HDPE pipes suitable for outdoor applications without the need for additional UV protection measures.

Hydraulic Properties:

HDPE pipes offer excellent hydraulic properties, providing a high flow rate with minimal head loss. This characteristic is advantageous for water distribution systems and other fluid transport applications.

Long Service Life:

HDPE pipes have a long service life and can withstand environmental stress cracking. They are resistant to aging and deterioration, contributing to a reliable and durable infrastructure.

Wide Temperature Range:

HDPE pipes can operate within a wide temperature range, making them suitable for both hot and cold fluid transport applications. They maintain their mechanical properties across a broad temperature spectrum.

Ease of Fusion Welding:

HDPE pipes can be joined using fusion welding techniques, creating strong and leak-resistant connections. Fusion welding also eliminates the need for adhesives or solvents.

Low Friction Coefficient:

HDPE exhibits a low friction coefficient, reducing energy losses and contributing to the overall efficiency of fluid transport systems.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português