Comparative analysis of the corrosion resistance of PPR Cap and the performance of traditional metal pipe fittings

PPR pipes and fittings have emerged as a preferred alternative to traditional metal pipe fittings due to their superior corrosion resistance, ease of installation, and environmental benefits. This article presents a comprehensive comparative analysis between PPR caps and traditional metal pipe fittings, focusing on corrosion resistance, mechanical properties, longevity, maintenance requirements, and overall system performance. Additionally, this article highlights the expertise and product offerings of Shanghai Zhongsu Pipe Co., Ltd , a leading manufacturer in high-quality plastic piping systems.

Piping systems are essential components in residential, commercial, industrial, and municipal applications. Traditionally, metal pipes such as galvanized steel, copper, cast iron, and stainless steel were widely used for water supply, drainage, and heating systems. However, these materials are prone to corrosion over time, especially when exposed to moisture, chemicals, or aggressive environments. The development of thermoplastic piping systems like PPR has provided a durable and sustainable solution that addresses many of the limitations associated with metal piping.

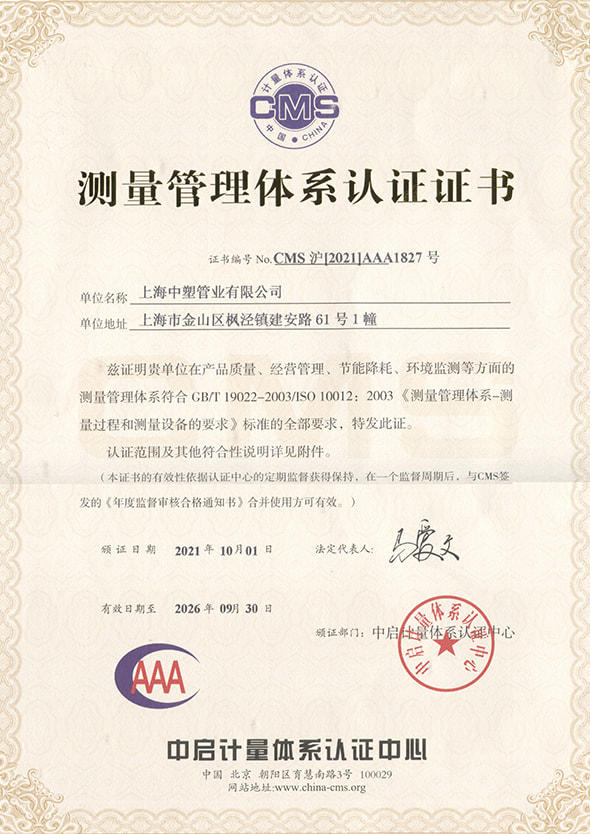

Shanghai Zhongsu Pipe Co., Ltd, established in 2004 with a registered capital of 1.01 billion RMB, is a pioneer in manufacturing high-performance plastic piping systems. Located in Jinshan District, Shanghai, China, and covering an area of 70,000 square meters, ZHSU specializes in producing PPR pipes and fittings, antibacterial PPR pipes, UV-resistant PPR pipes, PP-RCT pipes, and HDPE pipes. With advanced production lines and strict quality control measures, ZHSU ensures its products meet international standards while delivering superior performance in real-world conditions.

Understanding Corrosion in Metal Pipe Fittings

Corrosion is a natural electrochemical process that degrades metals when they react with their environment. In plumbing systems, corrosion can lead to pipe leakage, reduced flow capacity, water contamination, and eventual system failure. Traditional metal pipe fittings, including those made from iron, steel, and even copper, are vulnerable to several types of corrosion:

Oxidation (Rusting): Iron-based pipes form rust (iron oxide) when exposed to oxygen and moisture.

Galvanic Corrosion: Occurs when two dissimilar metals are connected in the presence of an electrolyte, causing accelerated degradation of one metal.

Pitting Corrosion: Localized corrosion that creates small holes in the metal surface, weakening structural integrity.

Microbiologically Influenced Corrosion (MIC): Microbial activity in water systems can accelerate corrosion processes.

These forms of corrosion not only shorten the service life of metal piping systems but also increase maintenance costs and pose risks to water quality.

Corrosion Resistance of PPR Caps

PPR caps and fittings offer a fundamentally different approach to corrosion resistance. As thermoplastic materials, PPR components do not undergo oxidation or chemical reactions with water, air, or most common chemicals found in plumbing systems. Here are some key reasons why PPR caps exhibit excellent corrosion resistance:

1. Chemical Inertness

PPR is chemically inert, meaning it does not react with water, acids, alkalis, or salts commonly present in domestic and industrial water supplies. This makes PPR ideal for use in aggressive environments where metal fittings would corrode rapidly.

2. No Electrochemical Reactions

Unlike metals, PPR is non-conductive and immune to galvanic corrosion. There is no risk of electrochemical degradation when PPR caps are used in mixed-material piping systems.

3. Longevity

PPR piping systems have an expected lifespan of over 50 years under normal operating conditions. Unlike metal fittings that degrade over time due to corrosion, PPR maintains its structural integrity and performance throughout its service life.

4. Hygienic Properties

ZHSU’s antibacterial PPR pipes and fittings incorporate additives that inhibit bacterial growth within the piping system, further enhancing the material's durability and safety for potable water applications.

5. UV and Heat Resistance

ZHSU offers anti-UV PPR pipes designed for outdoor installations, which resist degradation from sunlight exposure. Additionally, PPR can withstand temperatures up to 95°C for extended periods, making it suitable for both cold and hot water systems.

Comparative Performance: PPR vs. Traditional Metal Pipe Fittings

To better understand the advantages of PPR caps over traditional metal fittings, let's compare them across several performance criteria:

1. Corrosion Resistance

As previously discussed, PPR exhibits superior corrosion resistance compared to all types of metal fittings. While stainless steel and copper are more resistant than iron-based metals, they still experience corrosion over time, especially in saline or acidic environments. PPR, on the other hand, remains unaffected by water chemistry.

2. Installation and Maintenance

Metal fittings often require threading, welding, or soldering during installation, which increases labor costs and the potential for leaks. In contrast, PPR caps and fittings are joined using heat fusion technology, creating a seamless, leak-proof connection. This method is faster, cleaner, and requires less skilled labor.

Moreover, metal systems demand regular inspections and maintenance to address corrosion-related issues, whereas PPR systems require minimal upkeep.

3. Weight and Handling

PPR is significantly lighter than metal fittings, reducing transportation and handling costs. Its lightweight nature also makes it easier to install in tight spaces or multi-story buildings.

4. Cost Efficiency

While initial material costs for high-grade metals like copper may be comparable to PPR, the total lifecycle cost of PPR systems is generally lower due to reduced maintenance, longer lifespan, and ease of installation.

5. Environmental Impact

ZHSU uses 100% virgin raw materials from reputable brands such as Borealis, South Korea, and China, ensuring environmental friendliness and product safety. PPR is recyclable and does not release toxic substances during its lifecycle. In contrast, metal production involves higher energy consumption and carbon emissions, and corroded metal pipes can leach harmful ions into the water supply.

Applications and Market Reach of ZHSU Products

Shanghai Zhongsu Pipe Co., Ltd has built a robust product portfolio that includes:

PPR Water Supply Pipes & Fittings

Antibacterial PPR Pipes

Anti-UV PPR Pipes

PP-RCT Pipes & Fittings

HDPE Water Supply and Drainage Pipes

These products serve diverse sectors such as building water supply and drainage, municipal infrastructure, large-diameter underground drainage, sewage discharge, and rural water network transformation projects. ZHSU’s commitment to innovation is evident in its ability to produce HDPE pipes with diameters up to DN1200mm, meeting the demands of large-scale municipal and industrial projects, including nuclear power plant cooling systems.

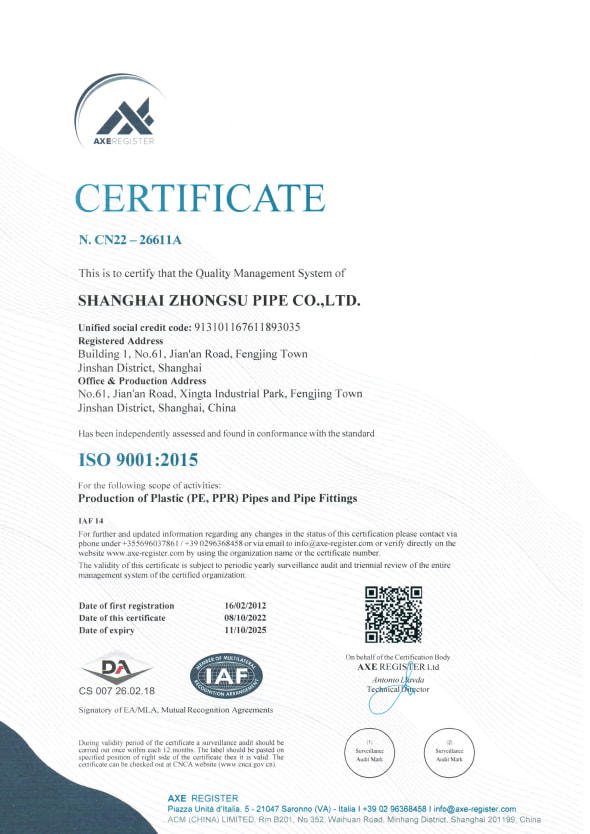

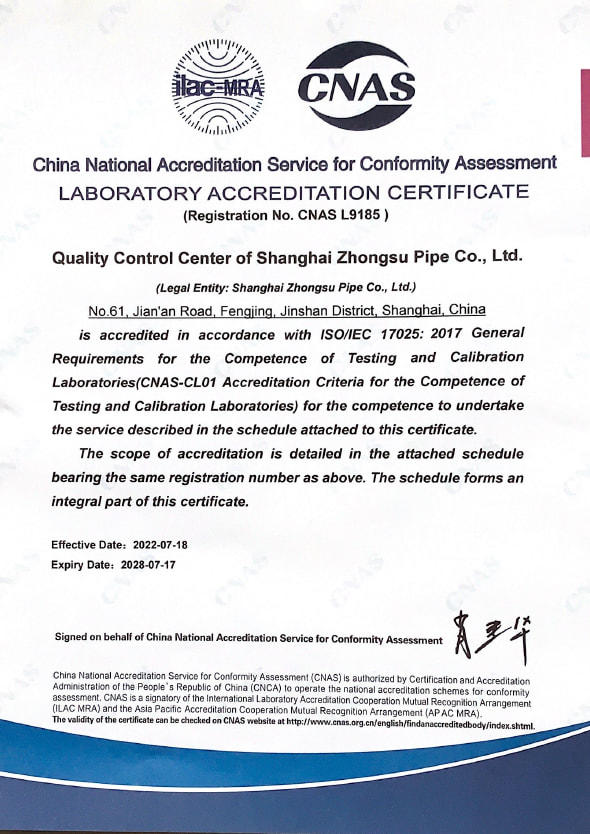

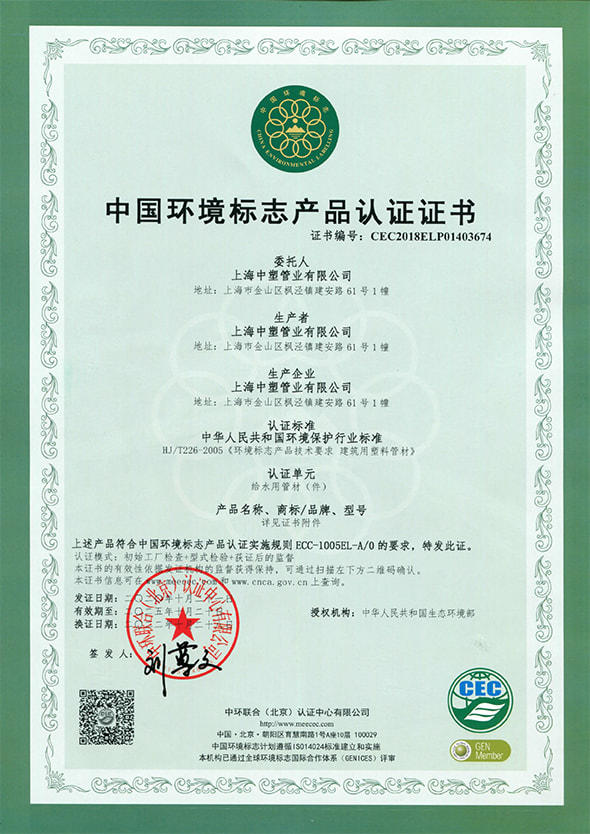

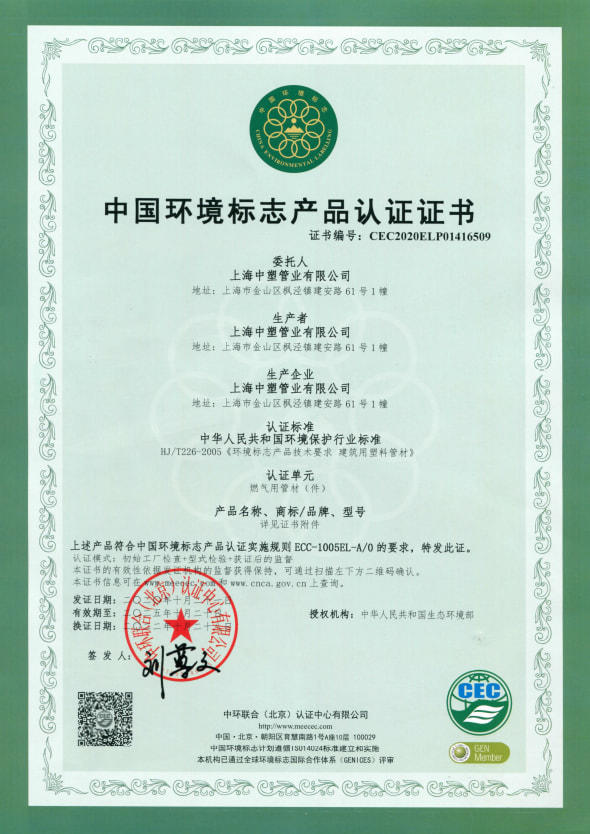

ZHSU’s products are not only popular within China but have also gained traction in international markets such as Southeast Asia, Africa, and Latin America. The company’s dedication to quality is reflected in its certifications, including ISO9001 (Quality Management), ISO14001 (Environmental Management), and OHSAS18001 (Occupational Health and Safety). Furthermore, ZHSU has been recognized as a "Shanghai Famous Brand Product," "Shanghai High-Tech Enterprise," and "Shanghai Famous Trademark."

The comparison between PPR caps and traditional metal pipe fittings clearly demonstrates the superiority of PPR in terms of corrosion resistance, durability, ease of installation, and environmental sustainability. While metal fittings have served the plumbing industry well for decades, their susceptibility to corrosion poses long-term risks and increased operational costs. On the other hand, PPR caps—especially those produced by leading manufacturers like Shanghai Zhongsu Pipe Co., Ltd—offer a reliable, cost-effective, and future-ready solution for modern piping systems.

ZHSU’s commitment to excellence, backed by state-of-the-art production facilities, certified quality management systems, and a wide range of innovative products, positions the company as a trusted partner for customers seeking high-performance plastic piping solutions. Whether for residential plumbing, municipal water networks, or industrial applications, PPR caps from ZHSU provide unmatched value and peace of mind.

As the global demand for sustainable and resilient infrastructure continues to grow, companies like ZHSU are at the forefront of driving innovation in the piping industry. By embracing core values such as customer-first service, technological advancement, and environmental responsibility, ZHSU is not only shaping the future of piping systems but also contributing to a safer, healthier, and more sustainable world.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português